Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Calibrating

Customer benefits

- High-quality, reproducible products due to planar and smooth belt transport

- Durable machine due to stable and high-quality construction

- High flexibility due to modular design (stations can be retrofitted) and universal holding devices

- Time saving and improved user comfort thanks to electric height adjustment

- Cost and space saving in dry treatment due to elimination of grinding water (no water treatment required) and special waste disposal

- Further cost cuttings possible due to the usage of dust which occurs during the calibration process as a filler in the concrete mixture

Application / Features

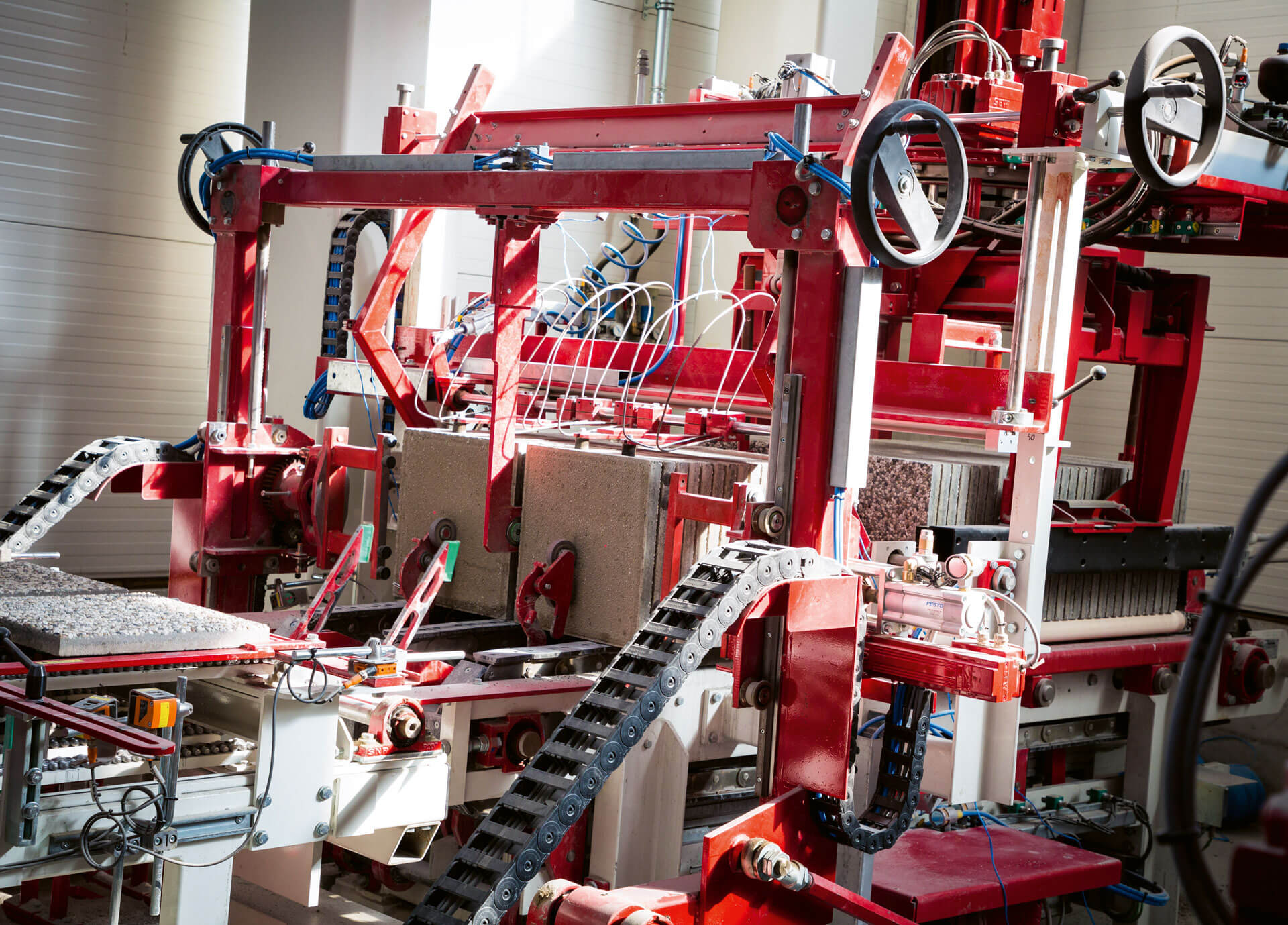

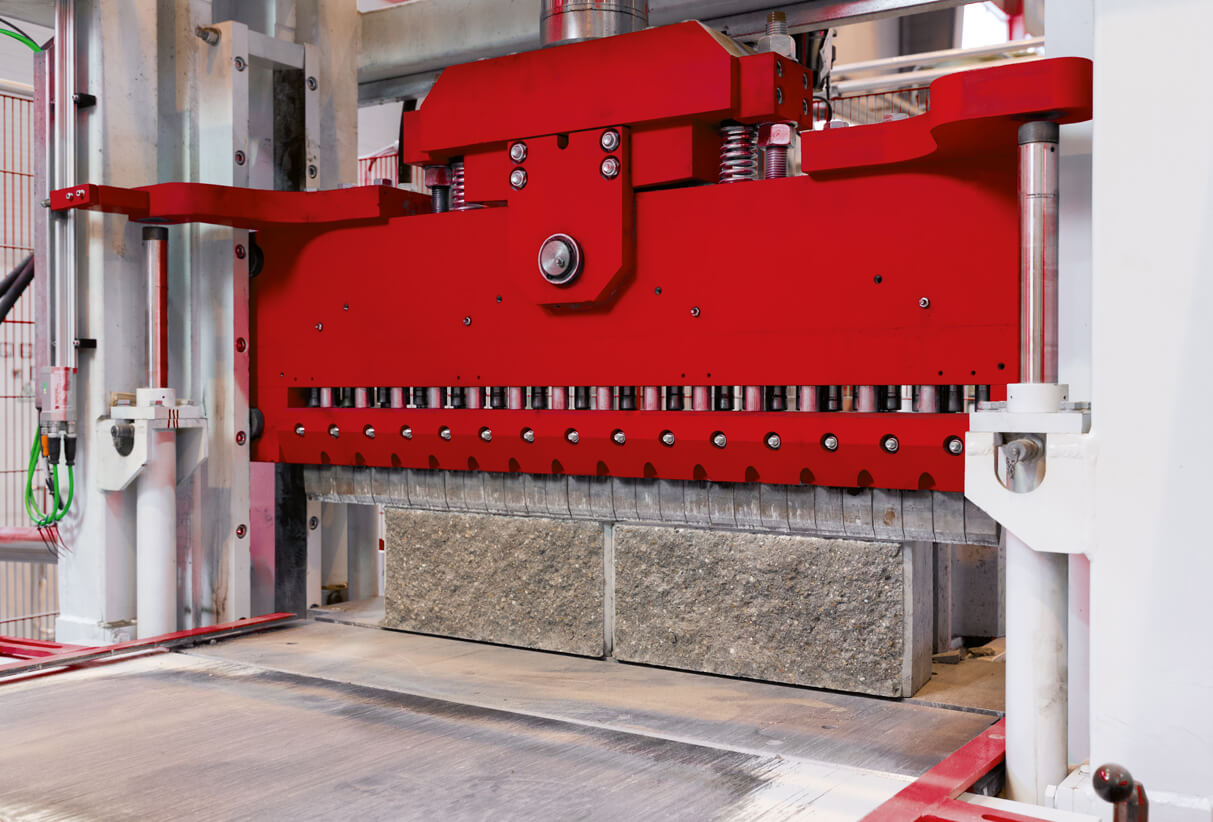

- The grinding machine serves to mill-off unevenesses of the surface of slabs and pavers which exceed the allowed production tolerances, i.e. variations of the height as well as of conicities

- Moreover, the machine can be used for the unilateral and bi-lateral layerwise milling of both wall stones and chimney stones in order to allow a mortar-free processing

- The treatment can be executed in dry mode or in wet mode

- Depending on the customer´s demand the machine can be equipped with up to 3 working stations

- Two working widths can be offered: 850 mm and 1,200 mm

- The machine is equipped with with lateral guidances which are optionally adjustable by means of an electric motor

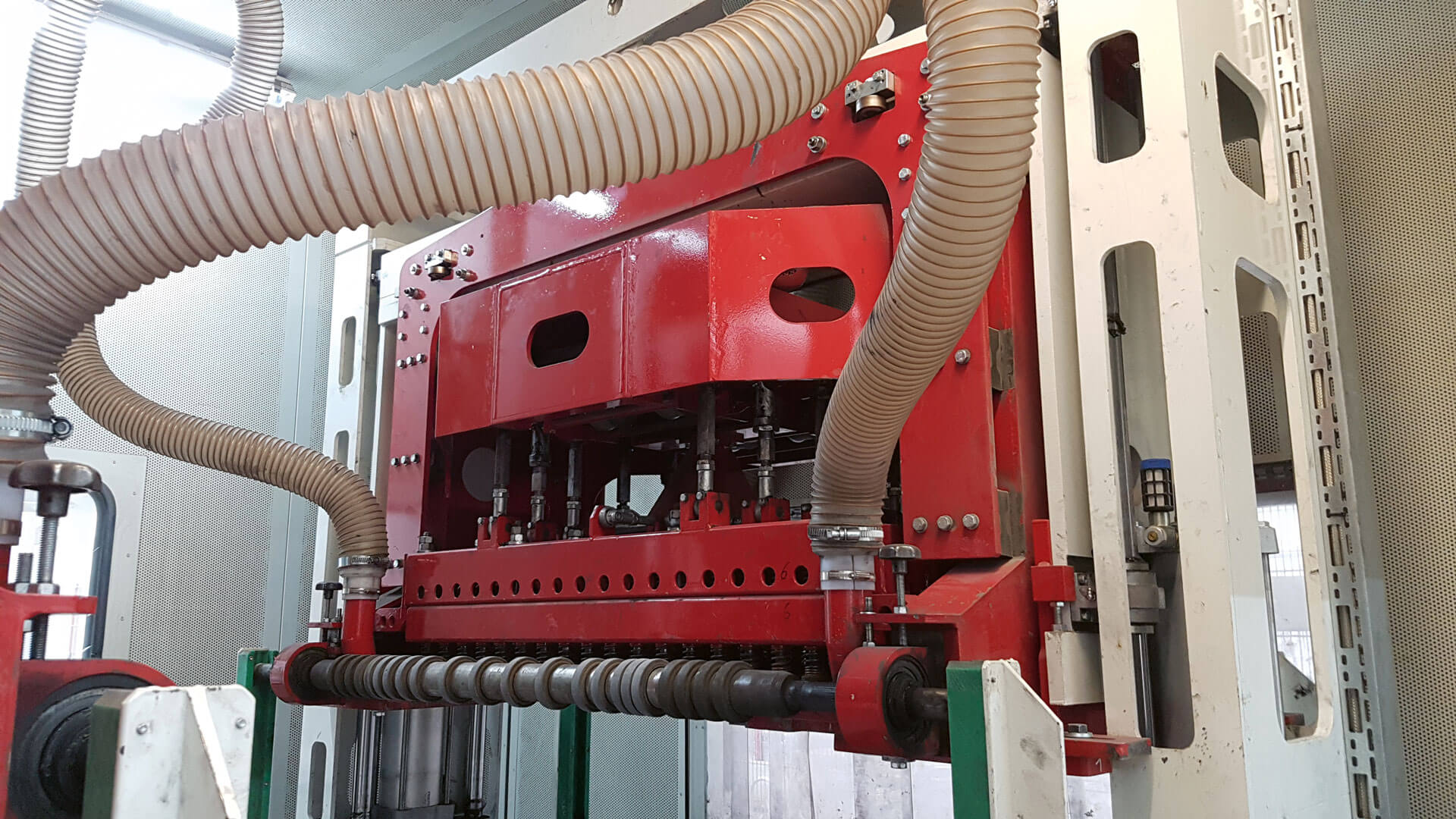

- Heavy-duty tunnel design

- Armoured machine bed, made from grey cast iron with hardened high-precision manganese steel ground plates

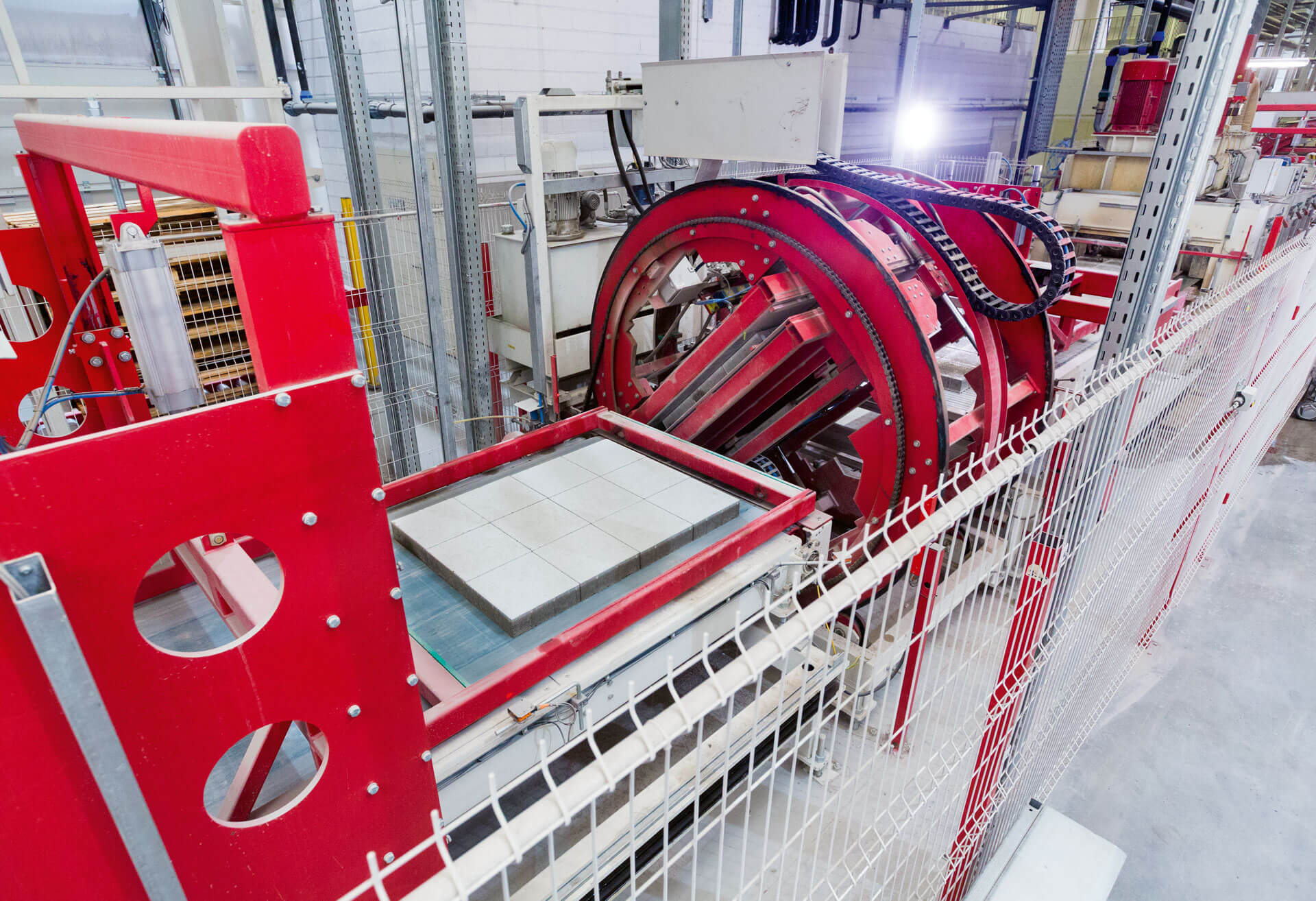

- Multi-layer armoured conveyor belt, make „Siegling“ for the planar transport of the products through the calibrating stations

- The calibrating stations are equipped with high-performance milling diamonds, attached to universal mounting devices

- Quick and easy tool exchange due to dovetail guidances

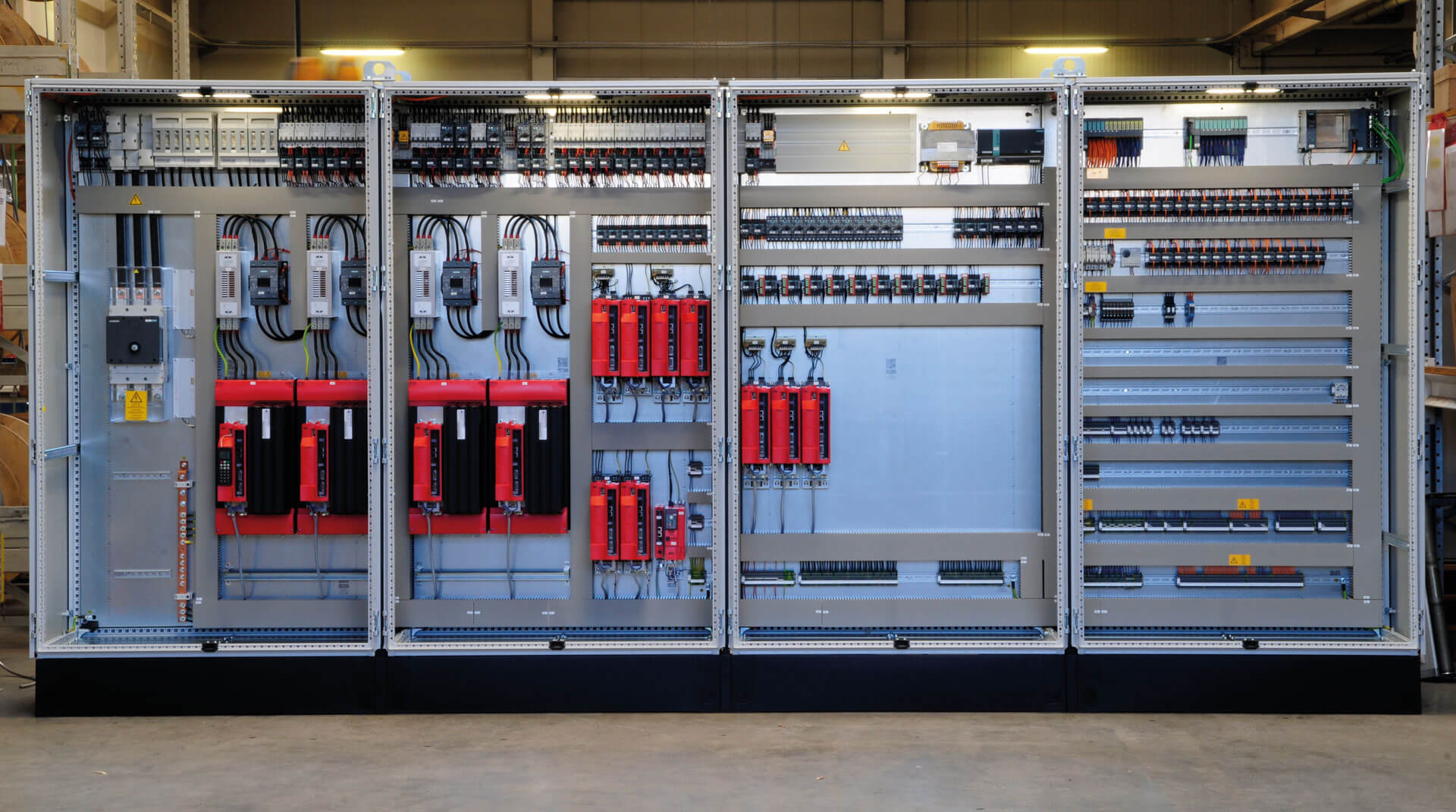

- VFD-driven main drives and vertical movement of each calibrating station

- Independant control and operation panel and visualization

- Processing parameters are being saved for each indivual product type

Technical specifications *

| Belt speed | 0.5 m/min up to 5 m/min |

| Average processing speed | |

| in wet mode | approx. 2-2,5 lin. m /min |

| in dry mode | approx. 1-1,5 lin. m /min |

| *depending on product characteristics and required final result | |

TECHNICAL DATA

Product thickness: 20 mm up to 400 mm

Working width: 850 mm / 1,200 mm

| Model | 850 | 1200 |

| 1 station | ||

| Length x width x height | 3,9 m x 2,2 m x 3,3 m | 5,4 m x 2,8 m x 3,6 m |

| Total connected load | up to 50 kW | up to 60 kW |

| Water consumption wet operation | up to 18 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 6,000 m3/h | up to 9,000 m3/h |

| 2 stations | ||

| Length x width x height | 5 m x 2,2 m x 3,3 m | 6,8 m x 2,8 m x 3,6 m |

| Total connected load | up to 95 kW | up to 110 kW |

| Water consumption wet operation | up to 24 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 12,000 m3/h | up to 18,000 m3/h |

| 3 stations | ||

| Length x width x height | 6,1 m x 1,9 m x 3,3 m | 8,3 m x 2,8 m x 3,5 m |

| Total connected load | up to 140 kW | up to 160 kW |

| Water consumption wet operation | up to 30 m3/h | up to 38 m3/h |

| Air consumption during dry operation | up to 18,000 m3/h | up to 27,000 m3/h |

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.