| Pallet depth minimum (mm) | 1100 |

| Pallet depth maximum (mm) | 1450 |

| Pallet width minimum (mm) | 1300 |

| Pallet width maximum (mm) | 1520 |

| Minimum manufacturing height (mm) | 25 |

| Maximum manufacturing height (mm) | 500 |

| Table vibration Variotronic, 1 table, pallet dept max. 1450 mm | Standard |

| Table vibration Variofrequency, 1 table, pallet depth max. 1300 mm | Option |

| Table vibration Variotronic, 2 tables, pallet depth 1150 mm and up | Option |

| Table vibration Variofrequency, 2 tables, pallet depth 1150 mm and up | Option |

| Standard hydraulics, Bosch-Rexroth | Standard |

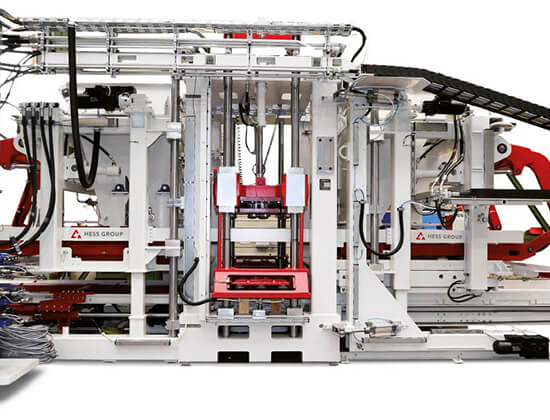

| MAC 8 control with 2 tamper head cylinders | Option |

| MAC 8 control with 4 tamper head cylinders | Option |

| Tamper head block height stop 4 pc. (with standard hydraulics) | Standard |

| Tamper head clamping, pneumatic | Standard |

| Tamper head clamping, hydraulic (Non Hess machine moulds) | Option |

| Tamper head cross cleaner, straight | Option |

| Mold clamping, pneumatic | Standard |

| Hydraulic function for mold flaps | Option |

| Electrical mold extension with pusher (for machines without face mix) | Option |

| Mold change, electrical | Standard |

| Mold change crane | Option |

| Hydraulic fast lift feeder (fast mold change) | Option |

| Horizontal adjustment table plate, electric | Option |

| Coarse mix part, movable, including pneumatic clamping | Option |

| Vertical adjustment table plate, electric | Standard |

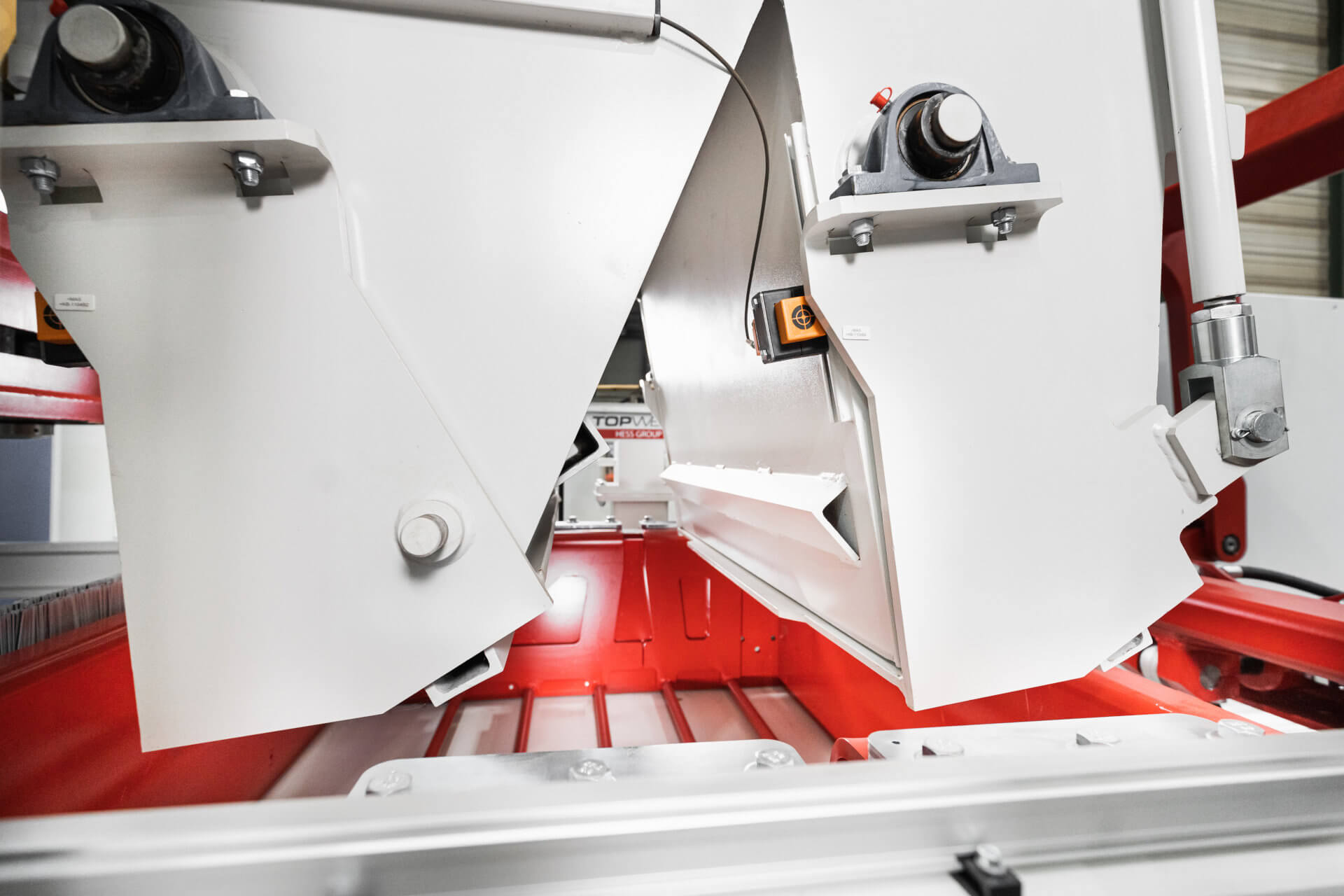

| Coarse mix silo 2 flapps | Option |

| Coarse mix Colormix drawplate | Option |

| Coarse mix silo, silo lining PA/Hardox | Option |

| Coarse mix filler box pneum. Scraper | Option |

| Agitator with cylinder drive | Standard |

| Face mix, electrically movable, including pneumatic clamping | Standard |

| Face mix Colormix drawplate | Option |

| Face mix silo, silo lining PA/Hardox | Option |

| Face mix filler box planing roller | Option |

| Face mix filler box pneum. Scraper | Option |

| Face mix filler box rotating brush (tamper head cleaning) | Option |

| Drawplate device build in pallet transport | Option |

| Drawplate device hydraulic / core pulling device | Option |

| Core pulling device, separately | Option |

| Styrofoam inserter, swivelingr | Option |

| Cooling tower for hydraulics | Option |

| Emergency operation hydraulics function | Option |