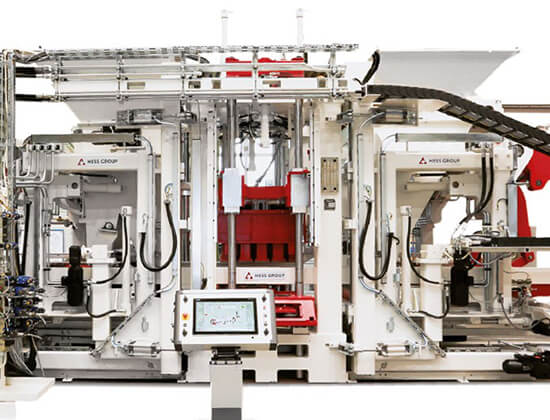

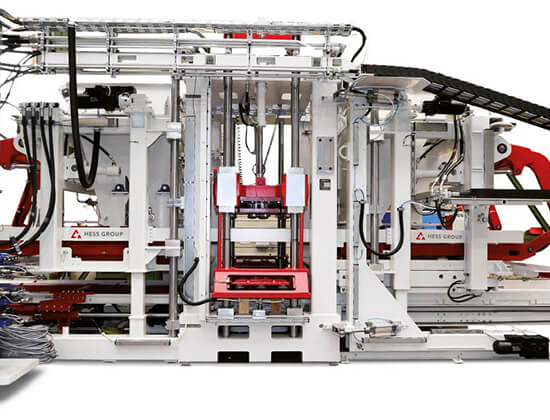

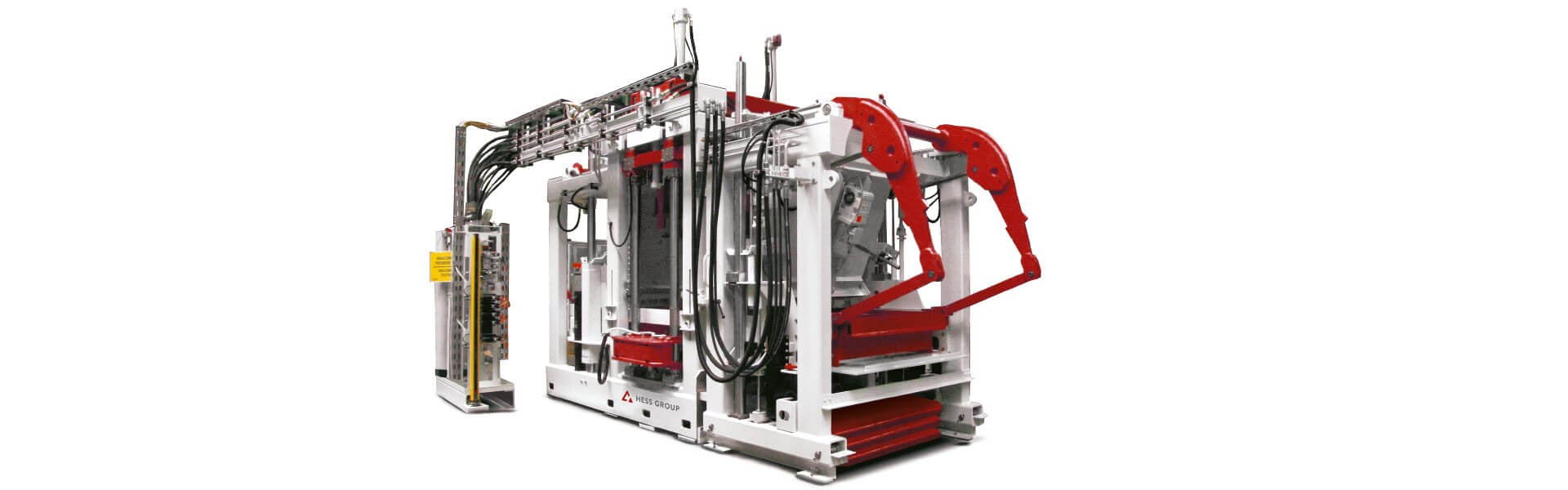

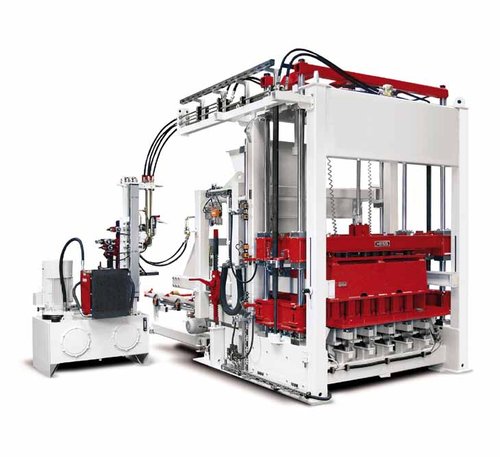

Concrete block machine

MULTIMAT RH 600-3

Advantages

- Operator controls with complete diagnostics

- The dimensional exactness and high density for

improved durability - Suitable for pavers, retaining walls, and hollow

block production and similar concrete products

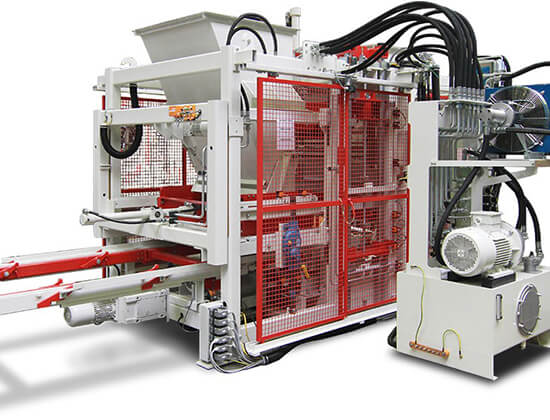

Standard equipment:

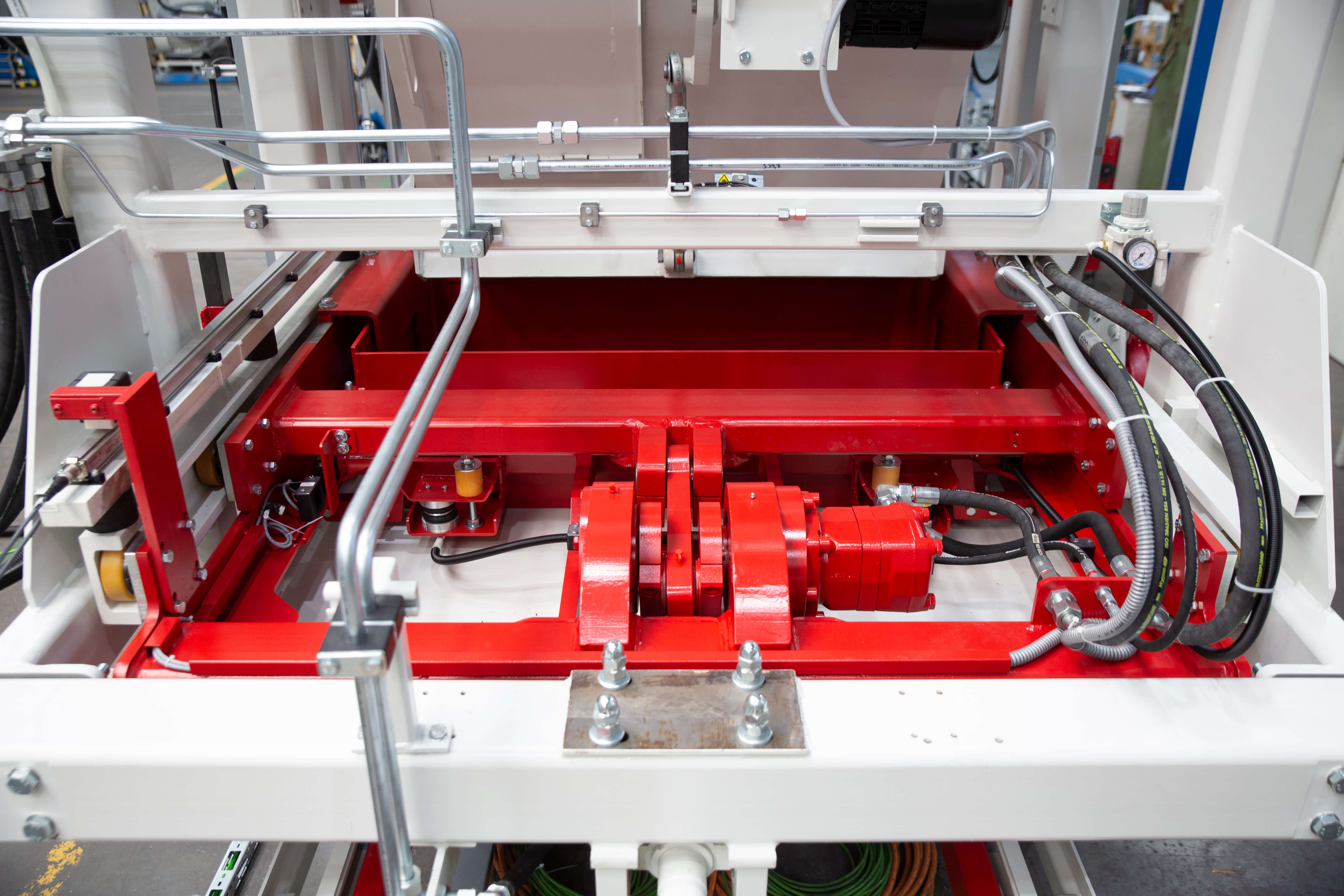

- Oil bath vibrators

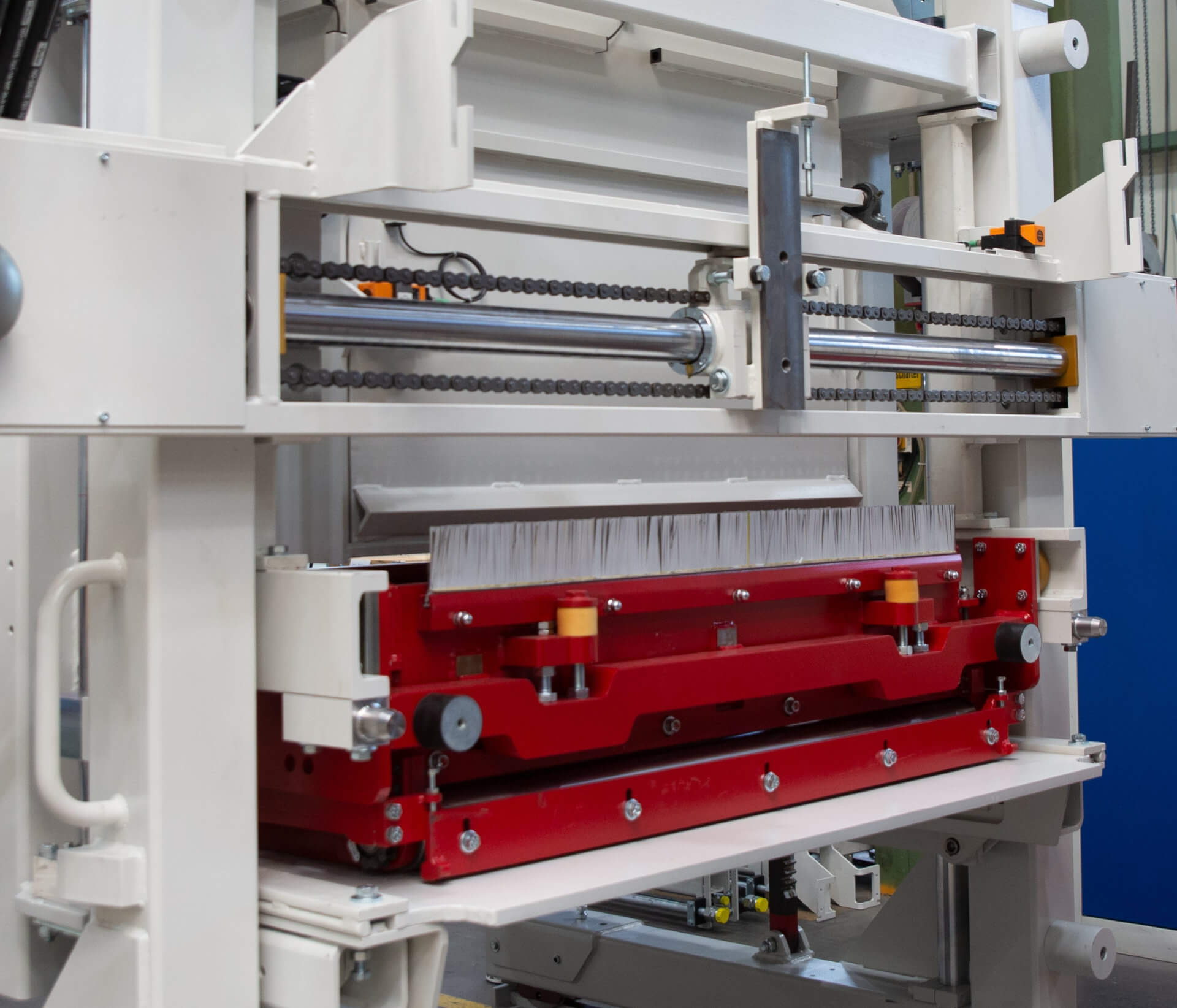

- Filler box with driven agitator

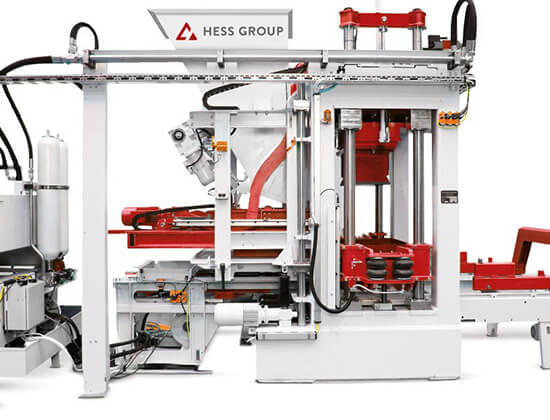

Modular structure

The RH 600 machine provides a modular structure to enable the producer to phase-in the level of automation as the market demands. The initial level of automation for the wet line or the dry line can be upgraded to a completely automated system in response to growth in market demand.

More information

Technical data