Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

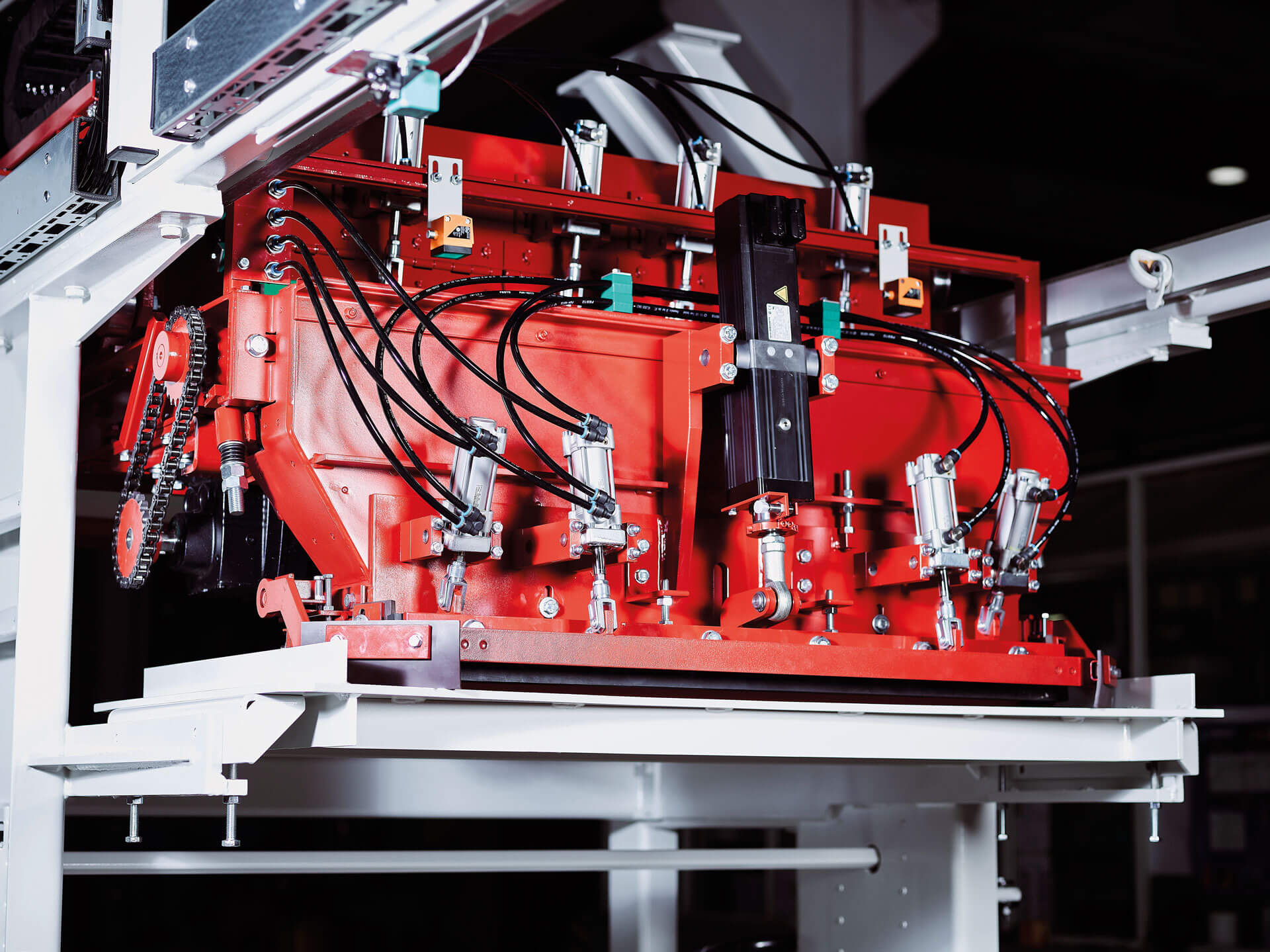

Station 7:

Ejection station

For ejection of green slabs from the press onto the slab depositing carriage. 2 ejection systems available.

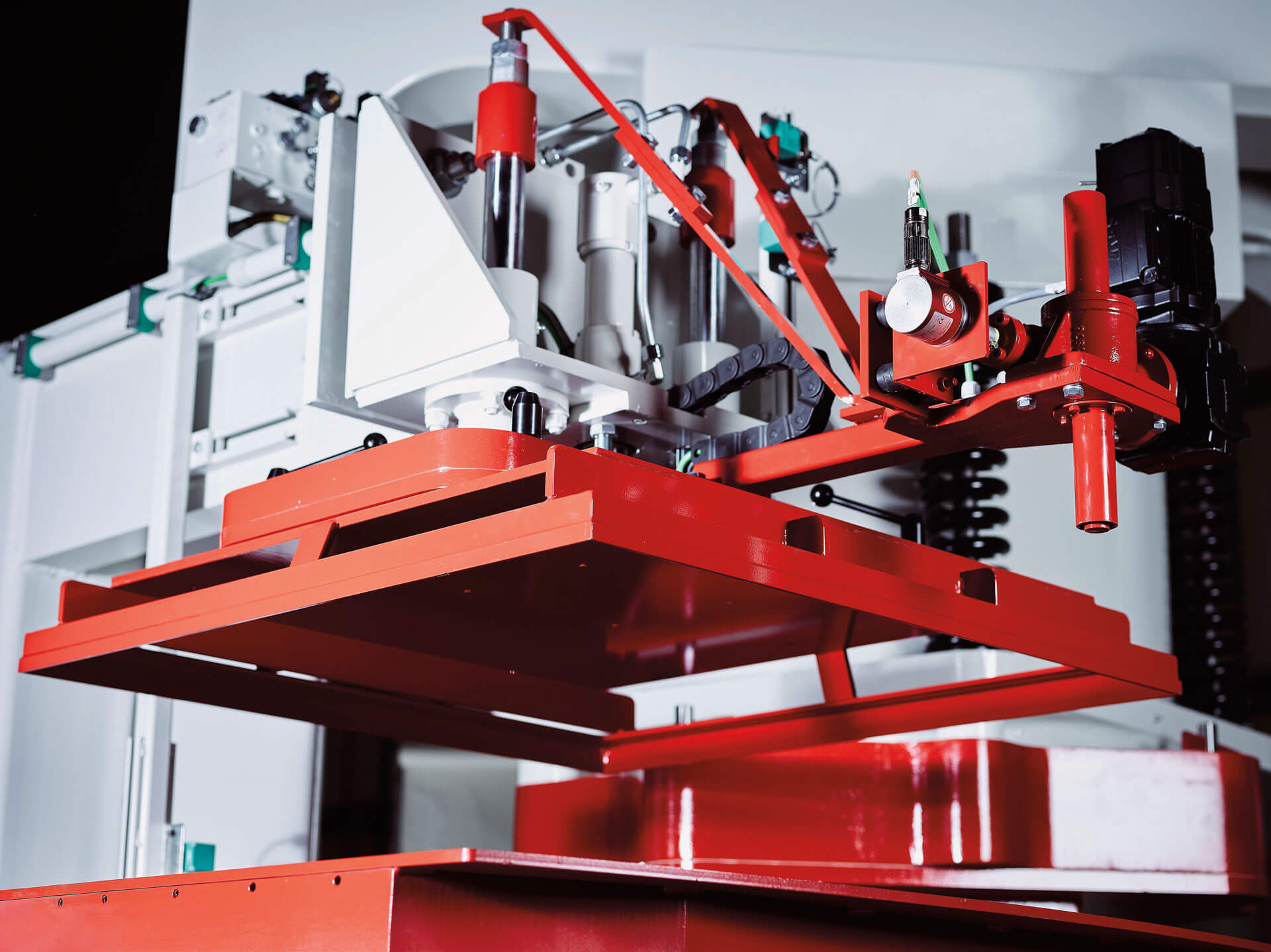

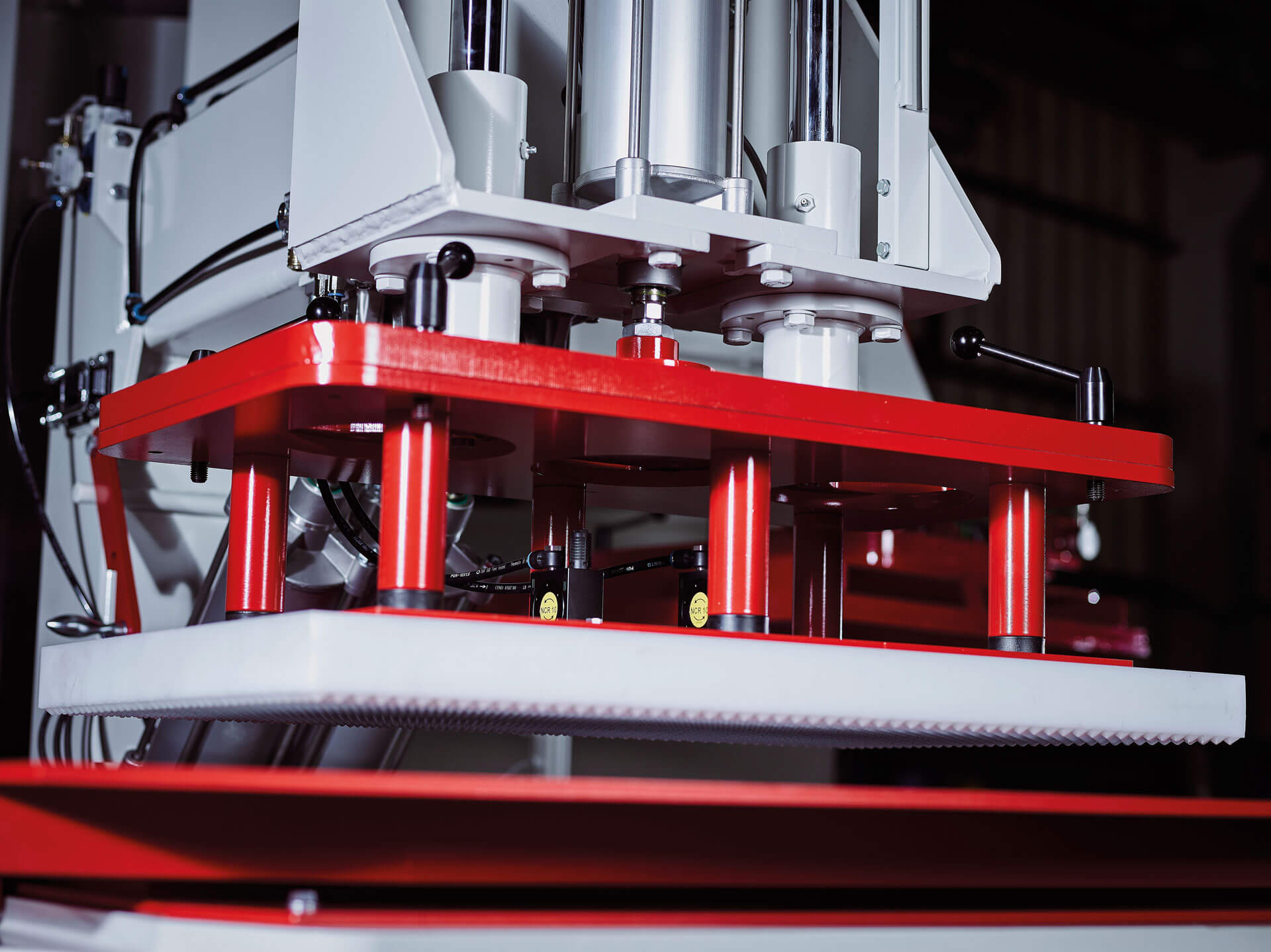

Mechanical ejection system

- Mould lifts

- Slab carriage moves below the mould

- Ejector pushes the slab out of the mould onto the carriage

System with electronic height adjustment during operation for compensation of differences in slab thickness.

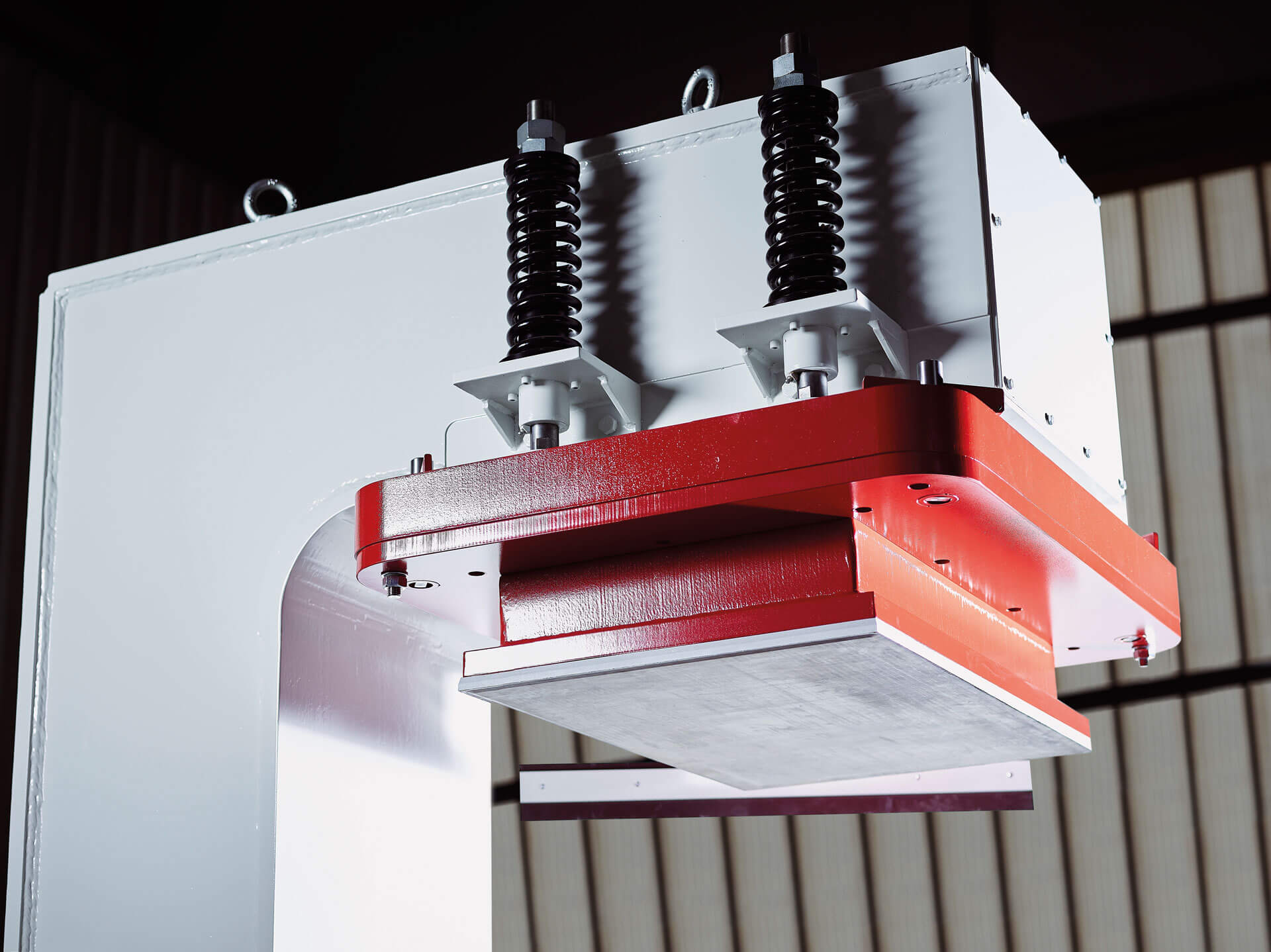

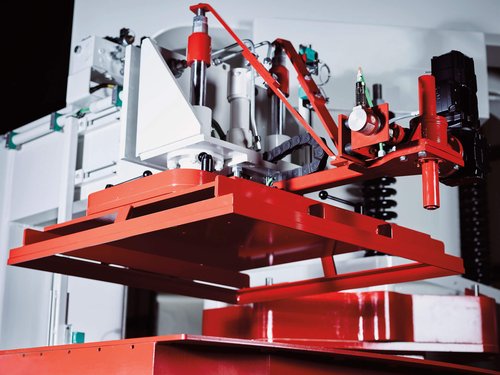

Optional: Vacuum-supported ejection system

Depending on format and slab thickness, a vacuum-supported ejection system is necessary.

- Ejector lowers towards the slab

- Mould moves upwards

- Vacuum is switched on

- Slab is lifted by ejector so that carriage can move below the product

- Slab is deposited by ejector on the carriage

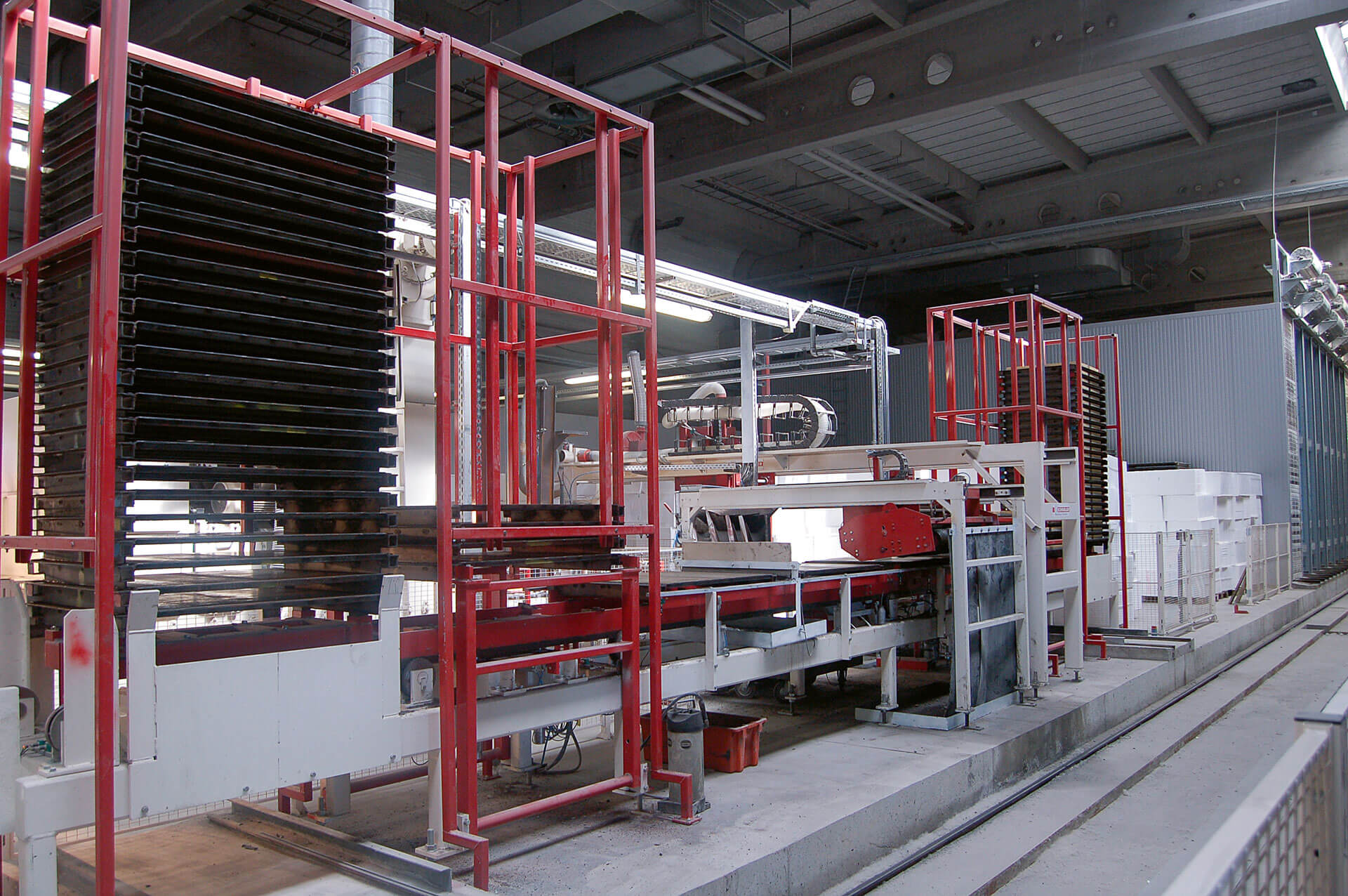

Slab depositing carriage

It is used to remove the green products from the press and for transfer to green slab turning device or direct pickup by means of slab transfer device of flat depositing device-wet side.

- Fully automated

- Fully capsulated

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.