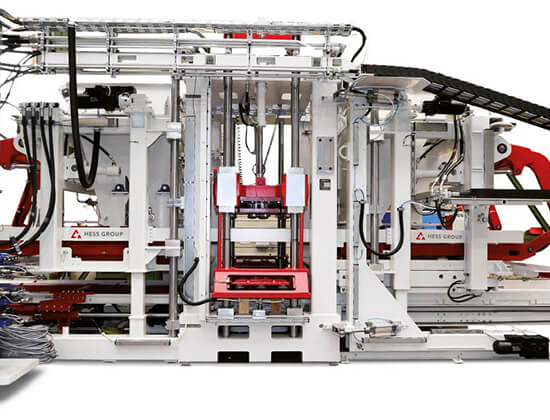

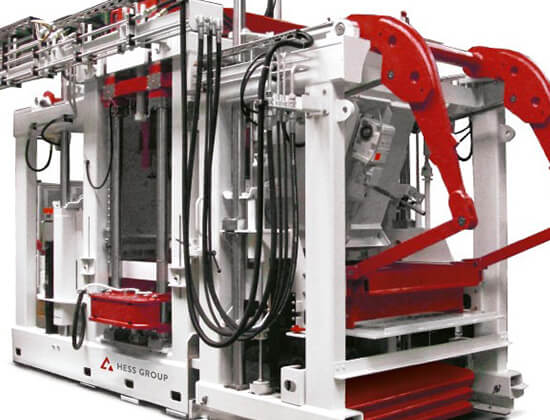

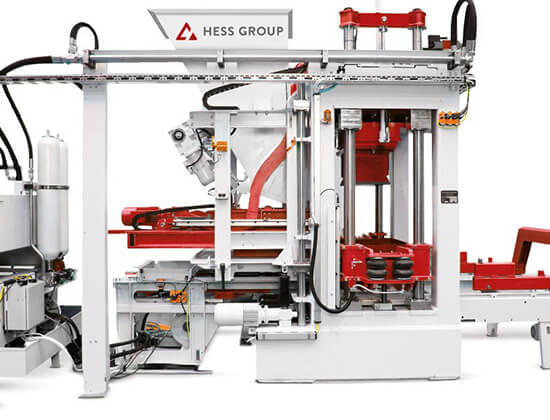

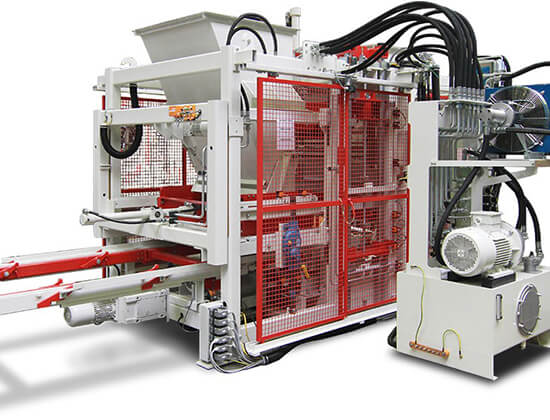

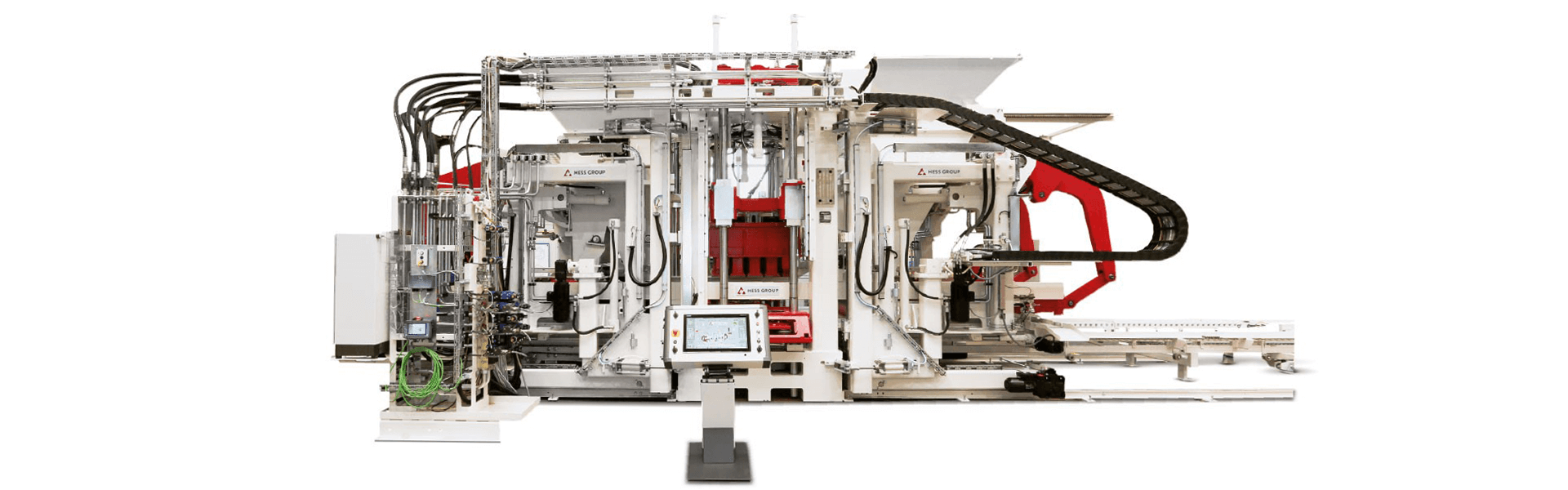

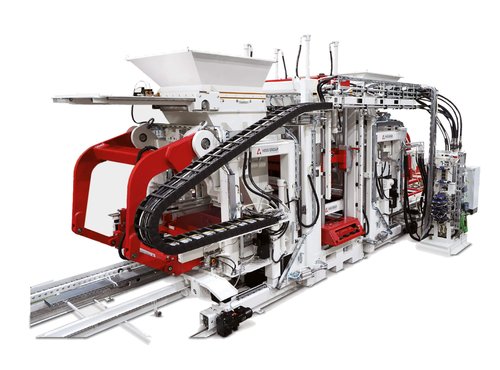

MULTIMAT

RH 2000-4 MVA

RH 2000 MVA 是海斯集团的高端设备。

混凝土砌块制造加工系统

混凝土砌块设备

MULTIMAT RH 2000-4 MVA

MULTIMAT RH 2000-4 MVA

这款高端生产机器将多年的机器制造经验与经过验证的最新 M-Version 技术相结合,为高质量混凝土产品创造可靠且可重复的性能水平。从最精确的尺寸公差到混凝土密度的最强耐久性,M 版 RH 2000 生产机器的平稳和轻松操作确保了生产商在其市场上的最大经济效益。 RH 2000-4 在其他人无法效仿的性能水平方面处于领先地位。

更多信息

技术参数

Technical data*

| production board (mm)** | 1.400 x 1.300 | |

| production area (mm)** | 1.300 x 1.250 | |

| min. product heigh (mm) | 25 | |

| max. product height (mm) | 500 | |

| dead weight approx. (kg) | 48.000 | |

| paver 10x20x6 without face mix | cycle time(s) | 10 |

| m² in 8h | 3.231 | |

| qty stones/form | 66 | |

| paver 10x20x6 with face mix | cycle time (s) | 11,5 |

| m² in 8h | 2.809 | |

| qty stones/form | 66 | |

| hollow block 20x40x20 | cycle time (s) | 13,5 |

| quantity in 8h | 32.640 | |

qty stones/form/td> | 18 | |

*Production capacities are calculated on 85% basis and depend on machine configuration, used recipes, raw materials, pallet handling, mold characteristics as well as

utilized production boards. Technical Data are subject to change. **other production board sizes available.

性能特点

| Pallet depth minimum (mm) | 1100 |

| Pallet depth maximum (mm) | 1450 |

| Pallet width minimum (mm) | 1300 |

| Pallet width maximum (mm) | 1520 |

| Minimum manufacturing height (mm) | 25 |

| Maximum manufacturing height (mm) | 500 |

| Table vibration Variotronic, 1 table, pallet dept max. 1450 mm | Standard |

| Table vibration Variofrequency, 1 table, pallet depth max. 1300 mm | Option |

| Table vibration Variotronic, 2 tables, pallet depth 1150 mm and up | Option |

| Table vibration Variofrequency, 2 tables, pallet depth 1150 mm and up | Option |

| Standard hydraulics, Bosch-Rexroth | Standard |

| MAC 8 control with 2 tamper head cylinders | Option |

| MAC 8 control with 4 tamper head cylinders | Option |

| Tamper head block height stop 4 pc. (with standard hydraulics) | Standard |

| Tamper head clamping, pneumatic | Standard |

| Tamper head clamping, hydraulic (Non Hess machine moulds) | Option |

| Tamper head cross cleaner, straight | Option |

| Mold clamping, pneumatic | Standard |

| Hydraulic function for mold flaps | Option |

| Electrical mold extension with pusher (for machines without face mix) | Option |

| Mold change, electrical | Standard |

| Mold change crane | Option |

| Hydraulic fast lift feeder (fast mold change) | Option |

| Horizontal adjustment table plate, electric | Option |

| Coarse mix part, movable, including pneumatic clamping | Option |

| Vertical adjustment table plate, electric | Standard |

| Coarse mix silo 2 flapps | Option |

| Coarse mix Colormix drawplate | Option |

| Coarse mix silo, silo lining PA/Hardox | Option |

| Coarse mix filler box pneum. Scraper | Option |

| Agitator with cylinder drive | Standard |

| Face mix, electrically movable, including pneumatic clamping | Standard |

| Face mix Colormix drawplate | Option |

| Face mix silo, silo lining PA/Hardox | Option |

| Face mix filler box planing roller | Option |

| Face mix filler box pneum. Scraper | Option |

| Face mix filler box rotating brush (tamper head cleaning) | Option |

| Drawplate device build in pallet transport | Option |

| Drawplate device hydraulic / core pulling device | Option |

| Core pulling device, separately | Option |

| Styrofoam inserter, swivelingr | Option |

| Cooling tower for hydraulics | Option |

| Emergency operation hydraulics function | Option |