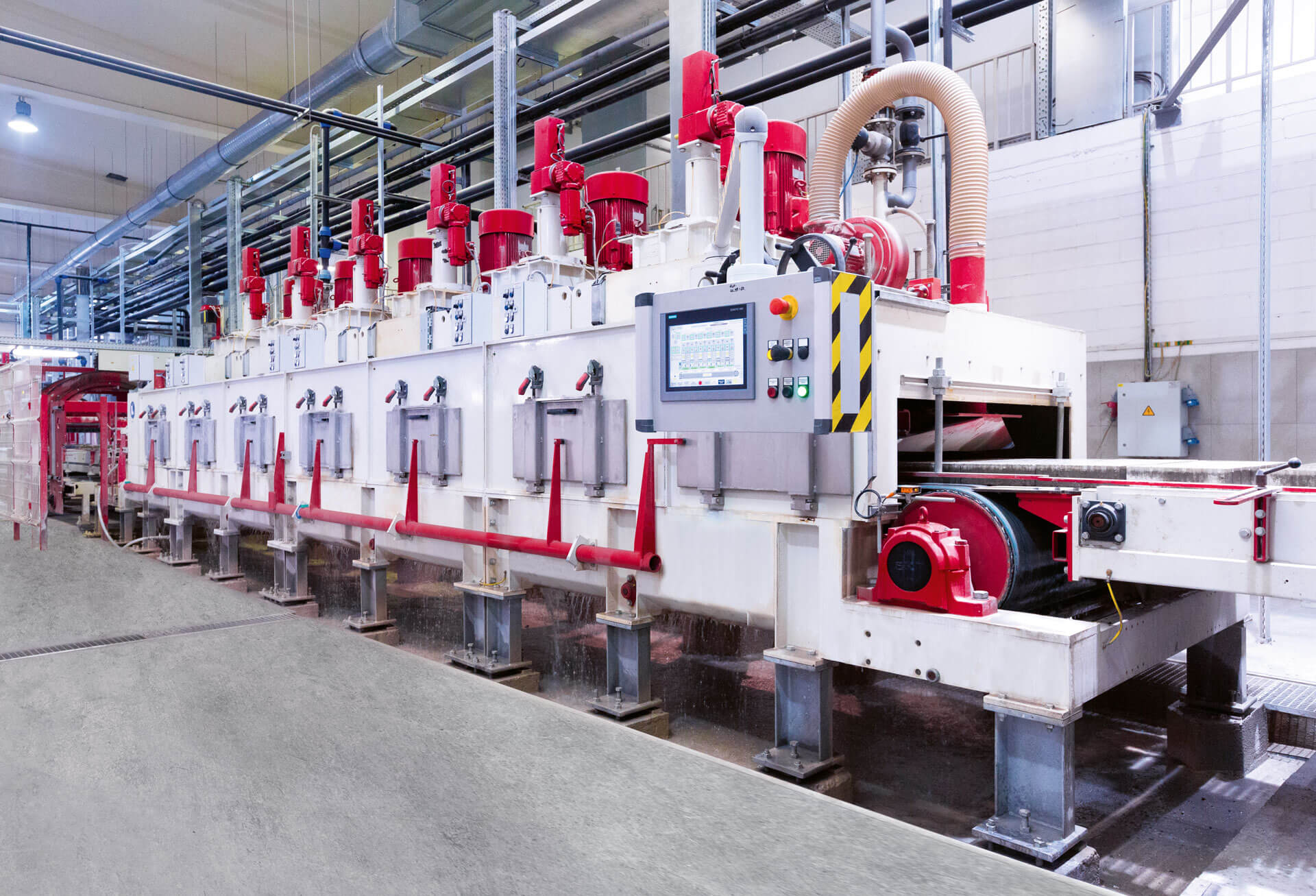

磨光工艺

客户的利益

- 平面和平滑的皮带传输带来高质量、可重复的产品

- 由于稳定和高质量的结构,机器经久耐用

- 由于模块化设计(工作站可以改装)和用于工艺工程的通用夹持盘,因此具有很高的灵活性

- 电动高度调节和全自动接触压力控制可节省时间并提高用户舒适度

- 由于消除了研磨水回收(无水处理)和特殊废物处理,干式处理节省了成本和空间

- 由于使用研磨过程中产生的灰尘作为混凝土混合物中的填料,可能进一步降低成本。

铺路石和平板的研磨。校准是获得最佳研磨结果的先决条件。校准后,产品在具有多达10个大功率工位的磨床中研磨。根据使用的研磨站数量,可以实现从粗糙到精细的表面外观。可以在干湿模式下进行处理。 10个工位的湿法处理,最大可达到220的研磨度。仅建议对硬石比例最大为 50% 的 facemix 进行干法处理。工作宽度为 850 和 1,200 毫米。

由钢制成的实心隧道式管片结构。由灰铸铁制成的铠装床身与高精度研磨锰硬化钢板和多层铠装西格林传送带,可将产品平面和平稳地输送通过站点。每个单独的工作站都可以配备铣削金刚石、平滑或研磨段。安装在通用夹持盘上的铣削金刚石、平滑或研磨段。通过燕尾导轨快速更换工具。

变频控制的主传动和各站的垂直运动。每个工位都有接触压力控制。机器配备了独立的控制和可视化操作面板。可以保存每种产品类型的加工参数。可与其他增值步骤相结合,如倒角、喷丸、卷曲、涂层和浸渍。

技术参数 *

| Belt speed | 0,5 - 5 m / Min |

| Average processing speed | |

| in wet mode | approx. 2-2,5 lin. m / Min |

| in dry mode | approx. 1-1,5 lin. m / Min |

| * depending on product characteristics and required final results | |

技术数据

产品厚度:20 mm up to 400 mm

工作宽度:850 mm / 1,200 mm

| Model | 850 | 1200 |

| 1 station | ||

| Length x width x height | 3,9 m x 2,2 m x 3,3 m | 5,4 m x 2,8 m x 3,6 m |

| Total connected load | up to 50 kW | up to 60 kW |

| Water consumption during wet operation | up to 18 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 6,000 m3/h | up to 9,000 m3/h |

| 2 stations | ||

| Length x width x height | 5 m x 2,2 m x 3,3 m | 6,8 m x 2,8 m x 3,6 m |

| Total connected load | up to 95 kW | up to 110 kW |

| Water consumption during wet operation | up to 24 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 12,000 m3/h | up to 18,000 m3/h |

| 4 stations | ||

| Length x width x height | 9,6 m x 2,2 m x 3,3 m | 11 m x 2,8 m x 3,6 m |

| Total connected load | up to 185 kW | up to 210 kW |

| Water consumption during wet operation | up to 30 m3/h | up to 48 m3/h |

| Air consumption during dry operation | up to 24,000 m3/h | up to 36,000 m3/h |

| 6 stations | ||

| Length x width x height | 10,5 m x 2,2 m x 3,3 m | 14 m x 2,8 m x 3,6 m |

| Total connected load | up to 275 kW | up to 310 kW |

| Water consumption during wet operation | up to 42 m3/h | up to 68 m3/h |

| Air consumption during dry operation | up to 36,000 m3/h | up to 54,000 m3/h |

| 8 stations | ||

| Length x width x height | 12 m x 2,2 m x 3,3 m | 17 m x 2,8 m x 3,6 m |

| Total connected load | up to 365 kW | up to 410 kW |

| Water consumption during wet operation | up to 54 m3/h | up to 88 m3/h |

| Air consumption during dry operation | up to 54,000 m3/h | up to 72,000 m3/h |

| 10 stations | ||

| Length x width x height | 14,2 m x 2,2 m x 3,3 m | 20 m x 2,8 m x 3,6 m |

| Total connected load | up to 455 kW | up to 510 kW |

| Water consumption during wet operation | up to 66 m3/h | up to 108 m3/h |

| Air consumption during dry operation | up to 60,000 m3/h | up to 90,000 m3/h |