Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Grinding

Customer benefits

- High-quality, reproducible products due to planar and smooth belt transport

- Durable machine due to stable and high-quality construction

- High flexibility due to modular design (stations can be retrofitted) and universal holding disc for process engineering

- Time saving and improved user comfort thanks to electric height adjustment and fully automated contact pressure control

- Cost and space saving in dry treatment due to elimination of grinding water recycling (no water treatment) and special waste disposal

- Further cost cuttings possible due to the usage of dust which occurs during the grinding process as a filler in the concrete mixture.

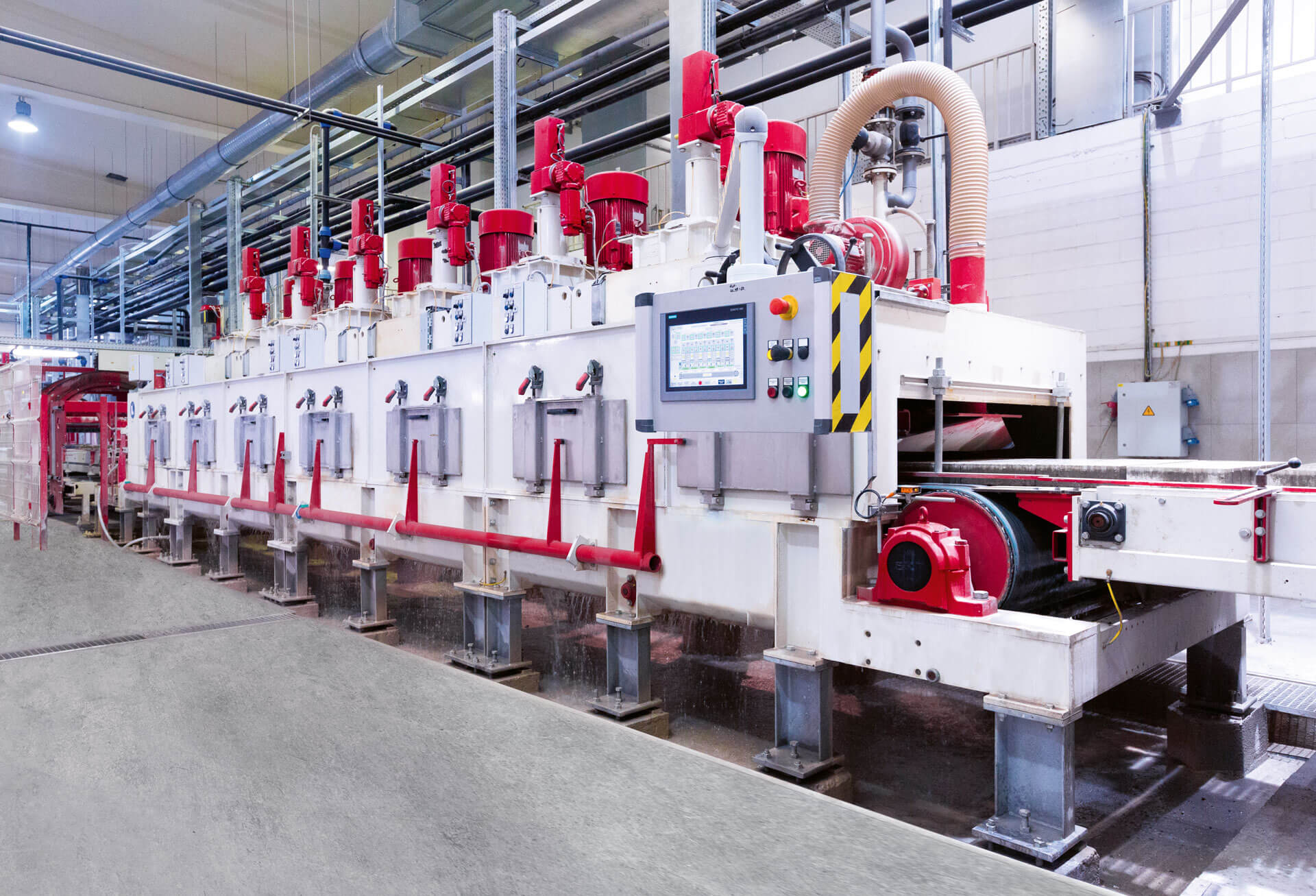

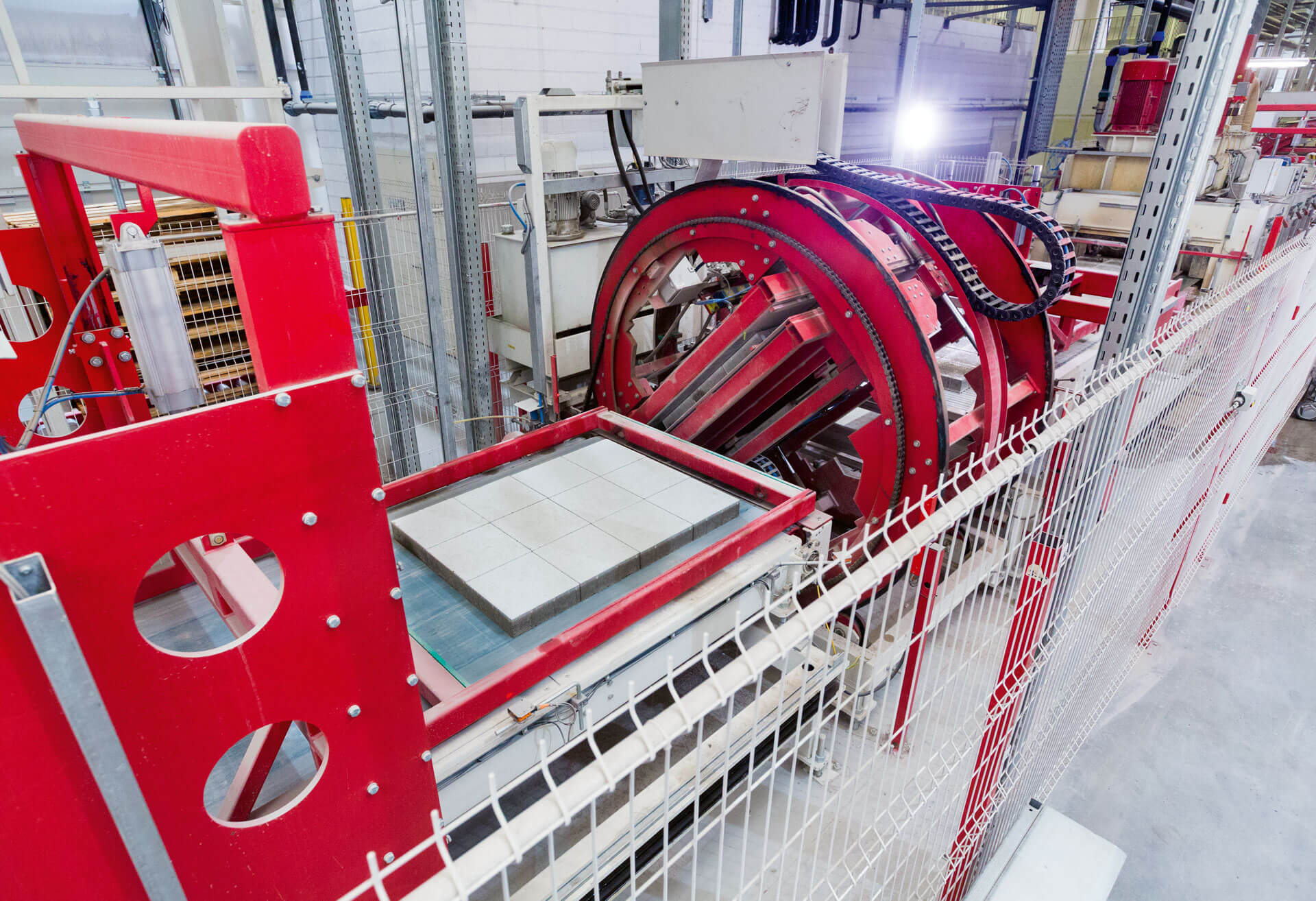

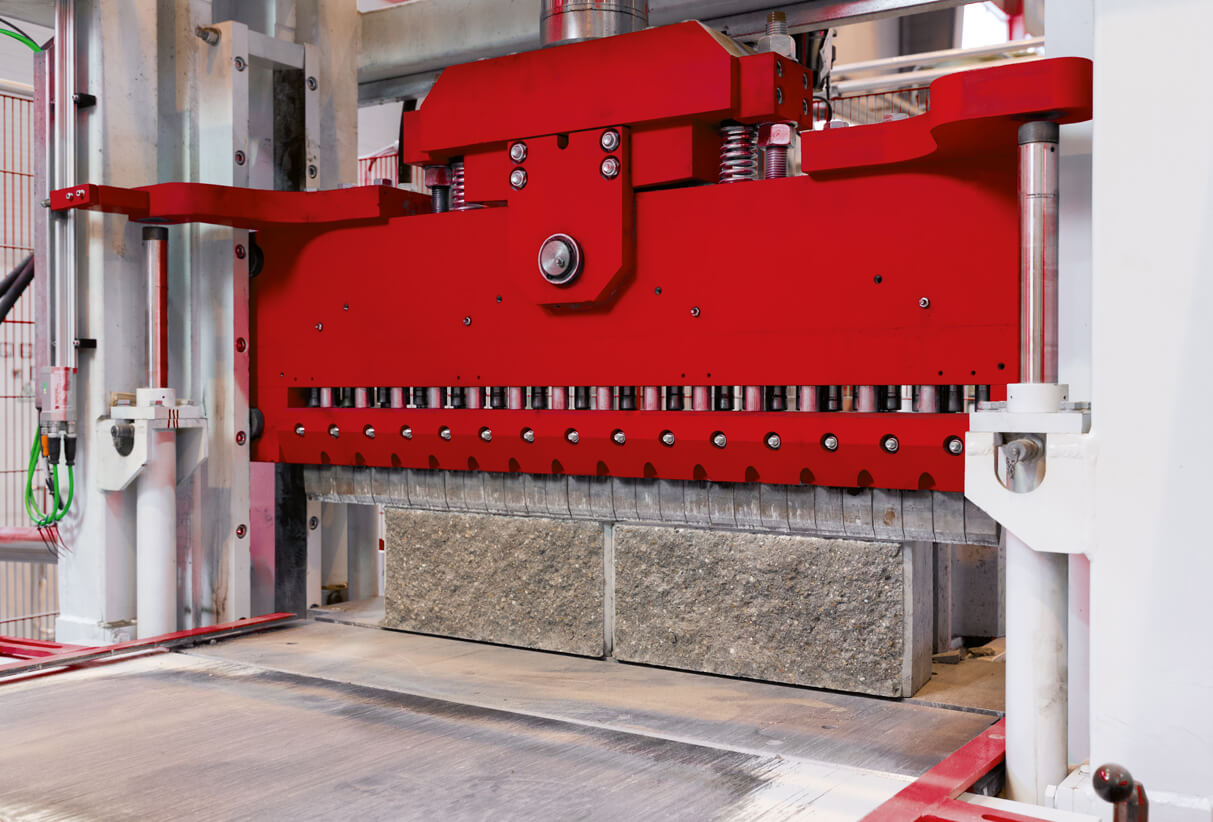

Grinding of pavers and slabs. Calibrating is a precondition for optimum grinding results. After calibration, products are ground in the grinding machine with up to 10 high-power stations. Depending on the number of grinding stations used, a surface appearance from rough to fine can be achieved. Treatment in dry and wet mode possible. In wet treatment with 10 stations, a grinding degree of maximum 220 can be reached. Dry treatment is recommendable only for facemix with a hard stone ratio of max. 50%. Working widths 850 and 1,200 mm.

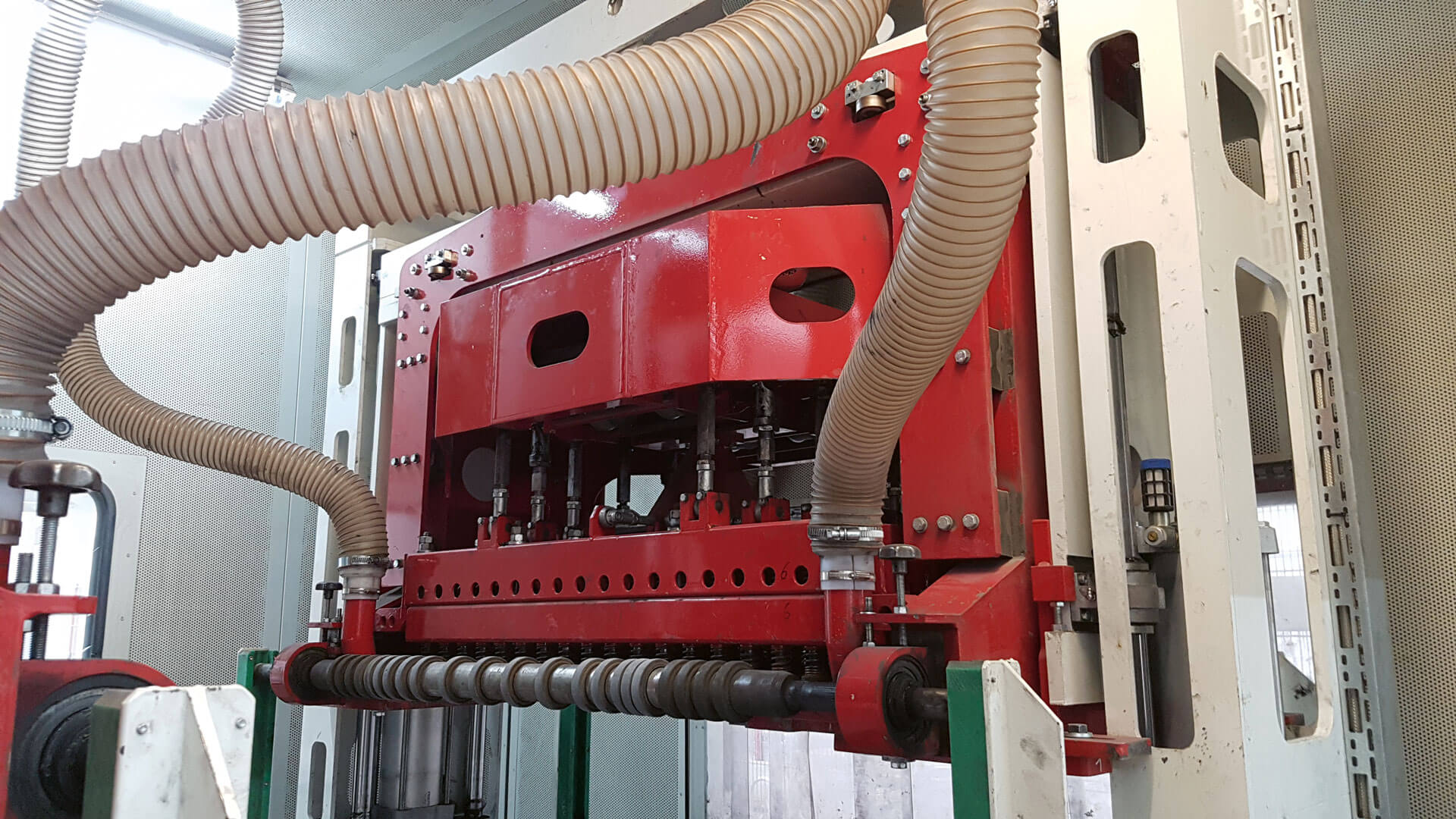

Solid tunnel type segment construction made of steel. Armoured bed made of rey cast iron with high-precision ground manganese hardened steel plates and multilayer armoured Siegling conveyor belt for planar and smooth transport of the products through the stations. Every individual station can be equipped with milling diamonds, smoothening or grinding segments. Milling diamonds, smoothening or grinding segments installed on universal holding discs. Quick tool exchange via dovetail guidances.

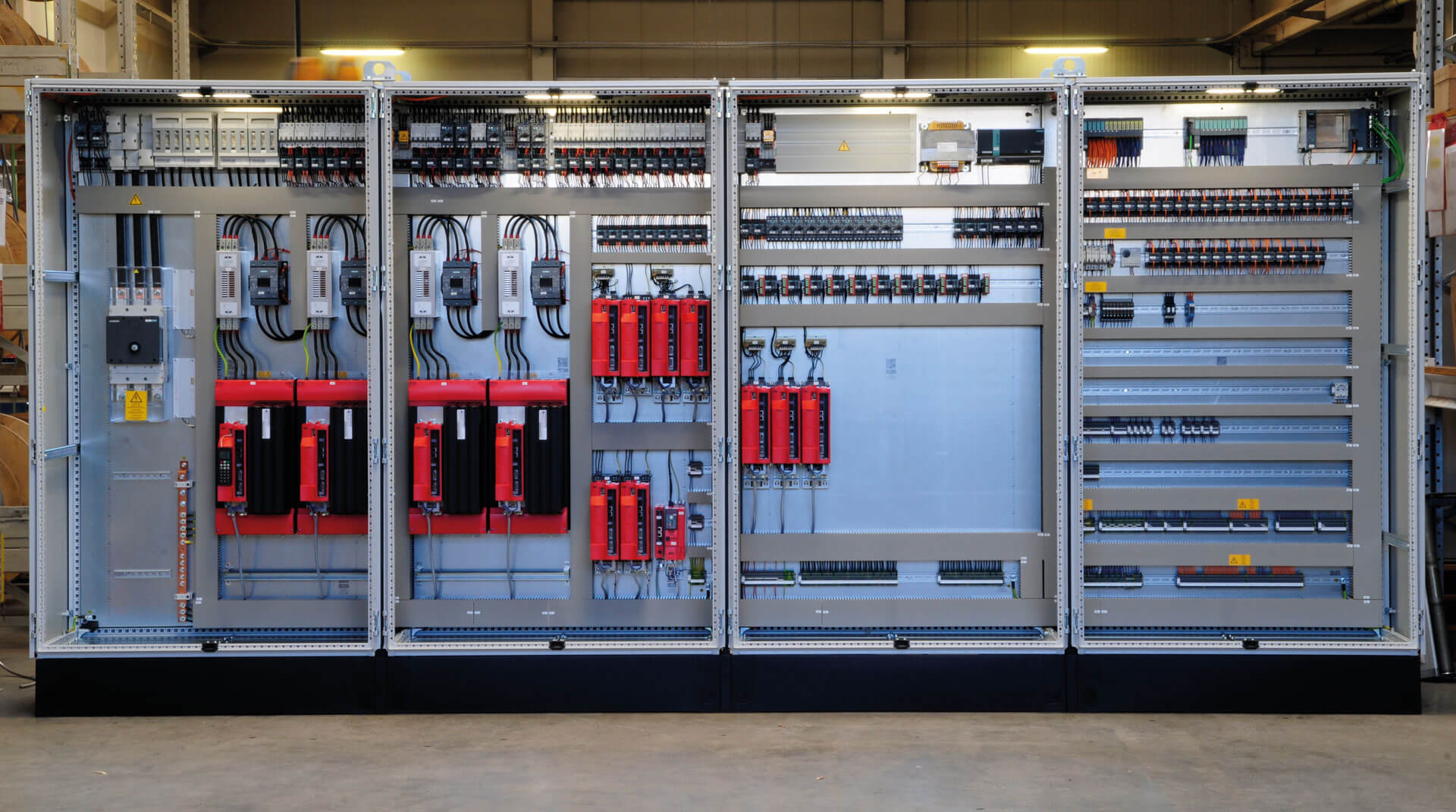

Frequency-controlled main drives and vertical movement of every station. Every station with contact pressure control. The machines are equipped with an independent control and operation panel with visualization. Processing parameters per product type can be saved. Can be combined with other value adding steps

like chamfering, shotblasting, curling, coating and impregnation.

Technical specifications *

| Belt speed | 0,5 - 5 m / Min |

| Average processing speed | |

| in wet mode | approx. 2-2,5 lin. m / Min |

| in dry mode | approx. 1-1,5 lin. m / Min |

| * depending on product characteristics and required final results | |

TECHNICAL DATA

Product thickness: 20 mm up to 400 mm

Working width: 850 mm / 1,200 mm

| Model | 850 | 1200 |

| 1 station | ||

| Length x width x height | 3,9 m x 2,2 m x 3,3 m | 5,4 m x 2,8 m x 3,6 m |

| Total connected load | up to 50 kW | up to 60 kW |

| Water consumption during wet operation | up to 18 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 6,000 m3/h | up to 9,000 m3/h |

| 2 stations | ||

| Length x width x height | 5 m x 2,2 m x 3,3 m | 6,8 m x 2,8 m x 3,6 m |

| Total connected load | up to 95 kW | up to 110 kW |

| Water consumption during wet operation | up to 24 m3/h | up to 28 m3/h |

| Air consumption during dry operation | up to 12,000 m3/h | up to 18,000 m3/h |

| 4 stations | ||

| Length x width x height | 9,6 m x 2,2 m x 3,3 m | 11 m x 2,8 m x 3,6 m |

| Total connected load | up to 185 kW | up to 210 kW |

| Water consumption during wet operation | up to 30 m3/h | up to 48 m3/h |

| Air consumption during dry operation | up to 24,000 m3/h | up to 36,000 m3/h |

| 6 stations | ||

| Length x width x height | 10,5 m x 2,2 m x 3,3 m | 14 m x 2,8 m x 3,6 m |

| Total connected load | up to 275 kW | up to 310 kW |

| Water consumption during wet operation | up to 42 m3/h | up to 68 m3/h |

| Air consumption during dry operation | up to 36,000 m3/h | up to 54,000 m3/h |

| 8 stations | ||

| Length x width x height | 12 m x 2,2 m x 3,3 m | 17 m x 2,8 m x 3,6 m |

| Total connected load | up to 365 kW | up to 410 kW |

| Water consumption during wet operation | up to 54 m3/h | up to 88 m3/h |

| Air consumption during dry operation | up to 54,000 m3/h | up to 72,000 m3/h |

| 10 stations | ||

| Length x width x height | 14,2 m x 2,2 m x 3,3 m | 20 m x 2,8 m x 3,6 m |

| Total connected load | up to 455 kW | up to 510 kW |

| Water consumption during wet operation | up to 66 m3/h | up to 108 m3/h |

| Air consumption during dry operation | up to 60,000 m3/h | up to 90,000 m3/h |

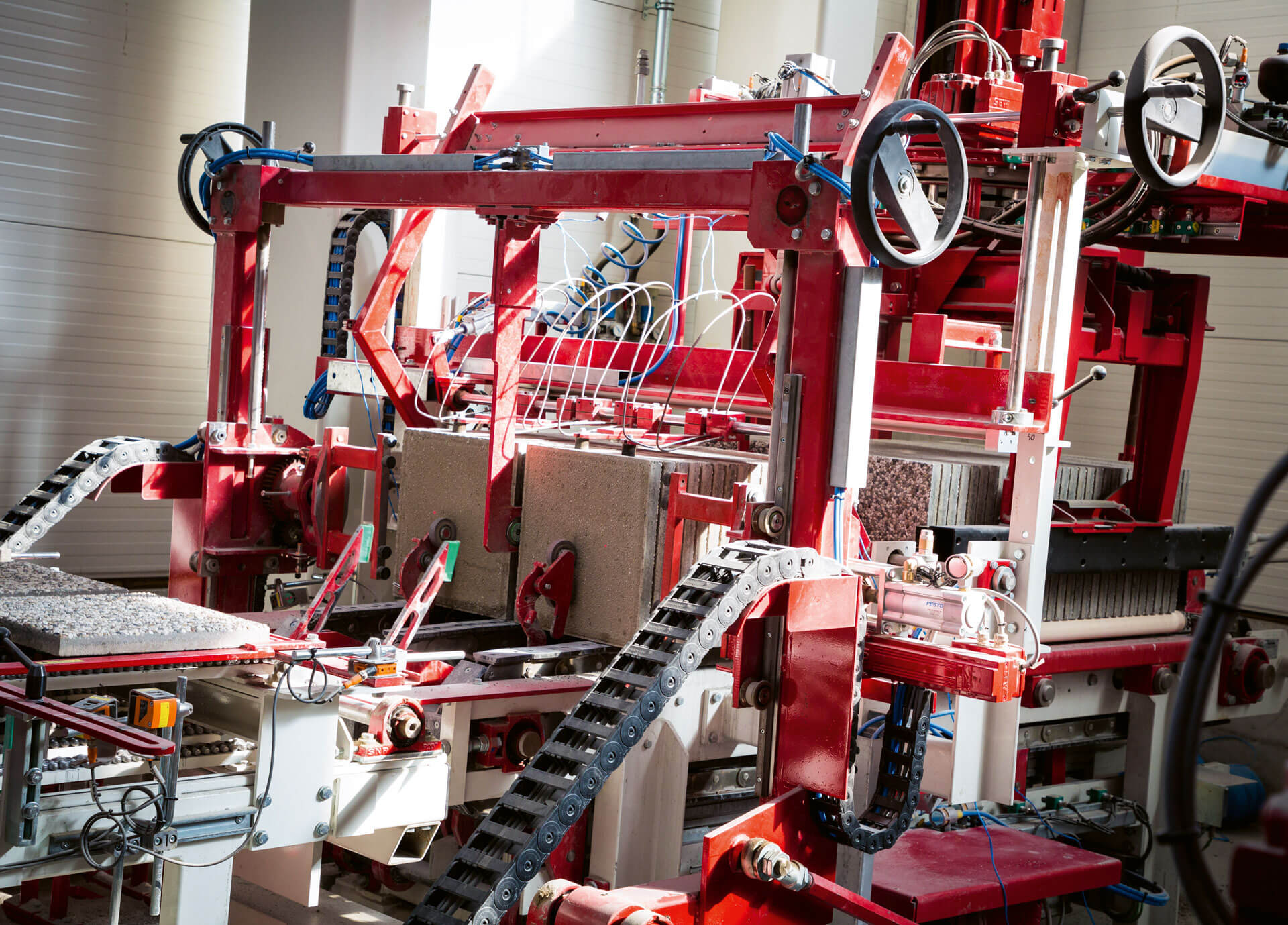

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.