Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

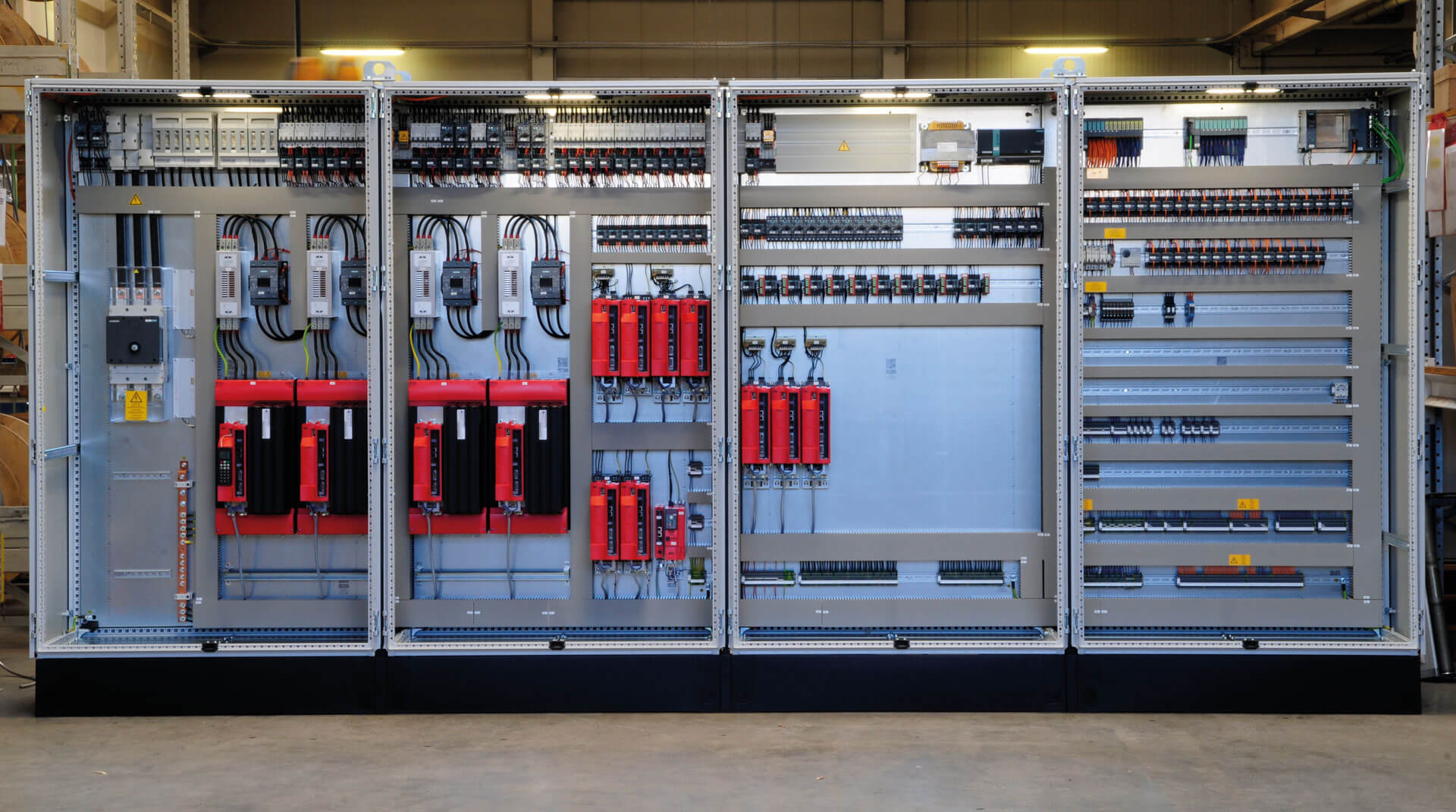

Control Technology

Customer benefits

- Cost saving due to high degree of automation and low personnel costs

- Greater profit margin due to higher productivity and increased efficiency

- Cost saving by reducing the error rate

- High plant availability due to minimized set-up times using servo drives and due to easy operation using system-specific and clear 3D visualization

- High adaptability, e.g. for the production of new product formats, due to in-house electrical development and software programming

- Guaranteed future security due to the latest control and bus systems

Control and visualization - everything under control

The highly flexible control technology by SR SCHINDLER enables you to increase the efficiency of your production plant. With the

SR SCHINDLER control systems, the focus is on simplified operation, reduction of operation costs and increase in quality.

Control

- Siemens Simatic-S7 1500

- Modular system for plant engineering, i.e. separation of the entire system and processing machines into individual controllers and decentralized I/O interfaces, for maximum flexibility and scalability, as well as efficient procedures at commissioning

Communication

- The entire system is consistently interlinked via Profinet, from the CPUs & HMI devices to decentralized input/output

modules, converters, sensors and actuators - IWLAN for mobile HMI devices. Wireless operating devices enable local adjustments and operator actions

- Profinet/Profisafe for safety-related communication and connection of safety technology

- Ensuring of remote maintenance at all levels via consistently interlinked plant components

- Complete integration of robot controls and third-party manufacturers in the overall plant control

Visualization/Operation and monitoring systems

- SIMATIC panel PC as touch screen and wireless operating devices

- Central recipe administration

- Operation and monitoring via plant-specific 3D visualization

- Continuous production data acquisition

Motors, servo drives and frequency converters

- Free adaptation of the plant parameters to different products, thus no adjustment of sensors, but only loading of parameters necessary

- Servo drives and frequency converters from SEW

Safety technology

- High level Siemens S7 F-CPU for safety programming

- Decentralized fail-safe input/output modules via Profisafe

- Overall visualization of safety technology for fast error detection and overview

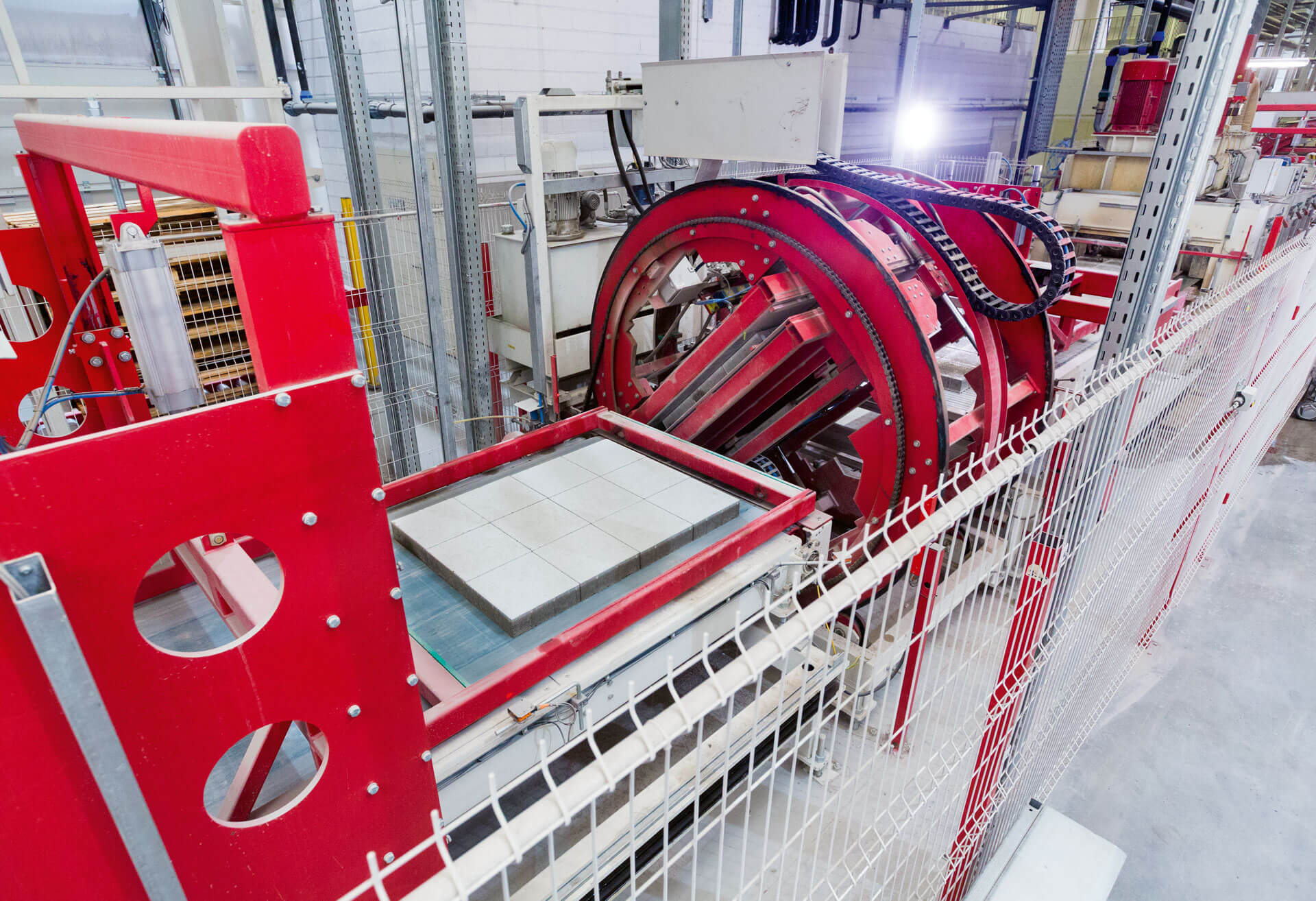

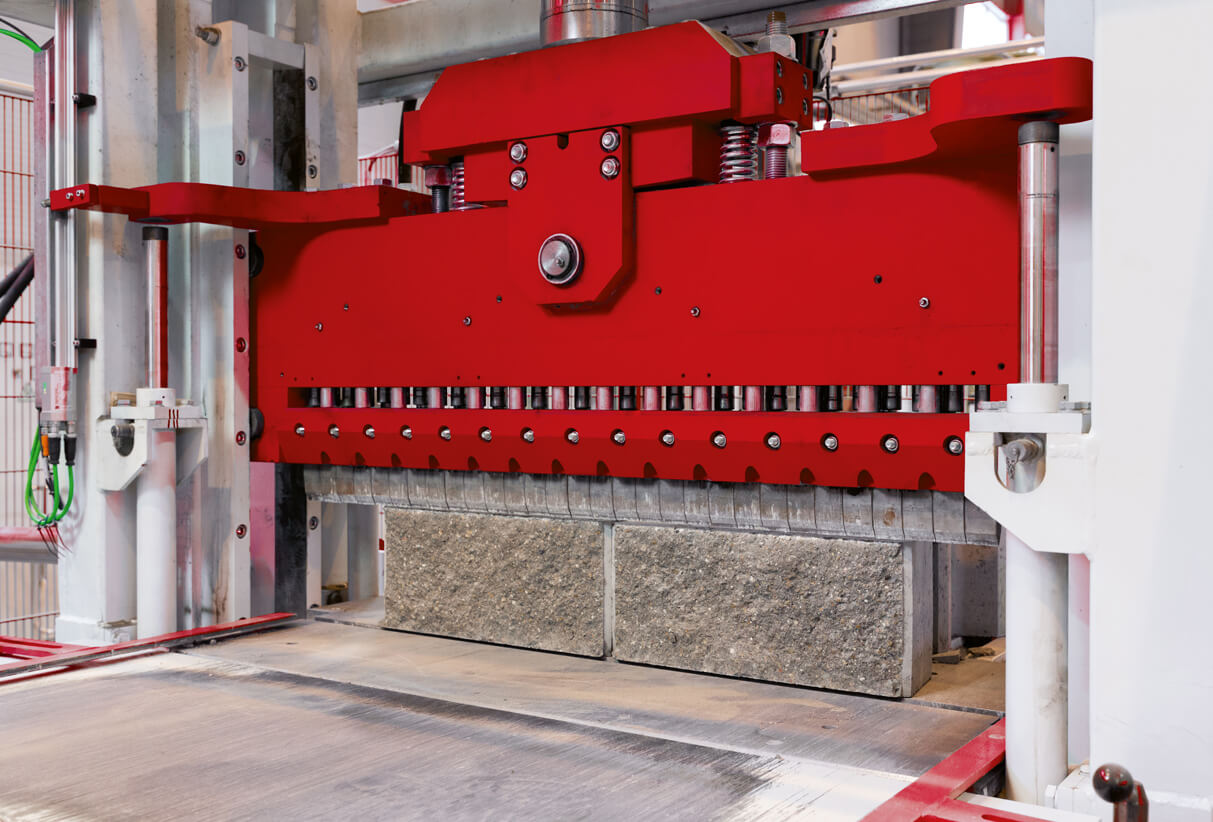

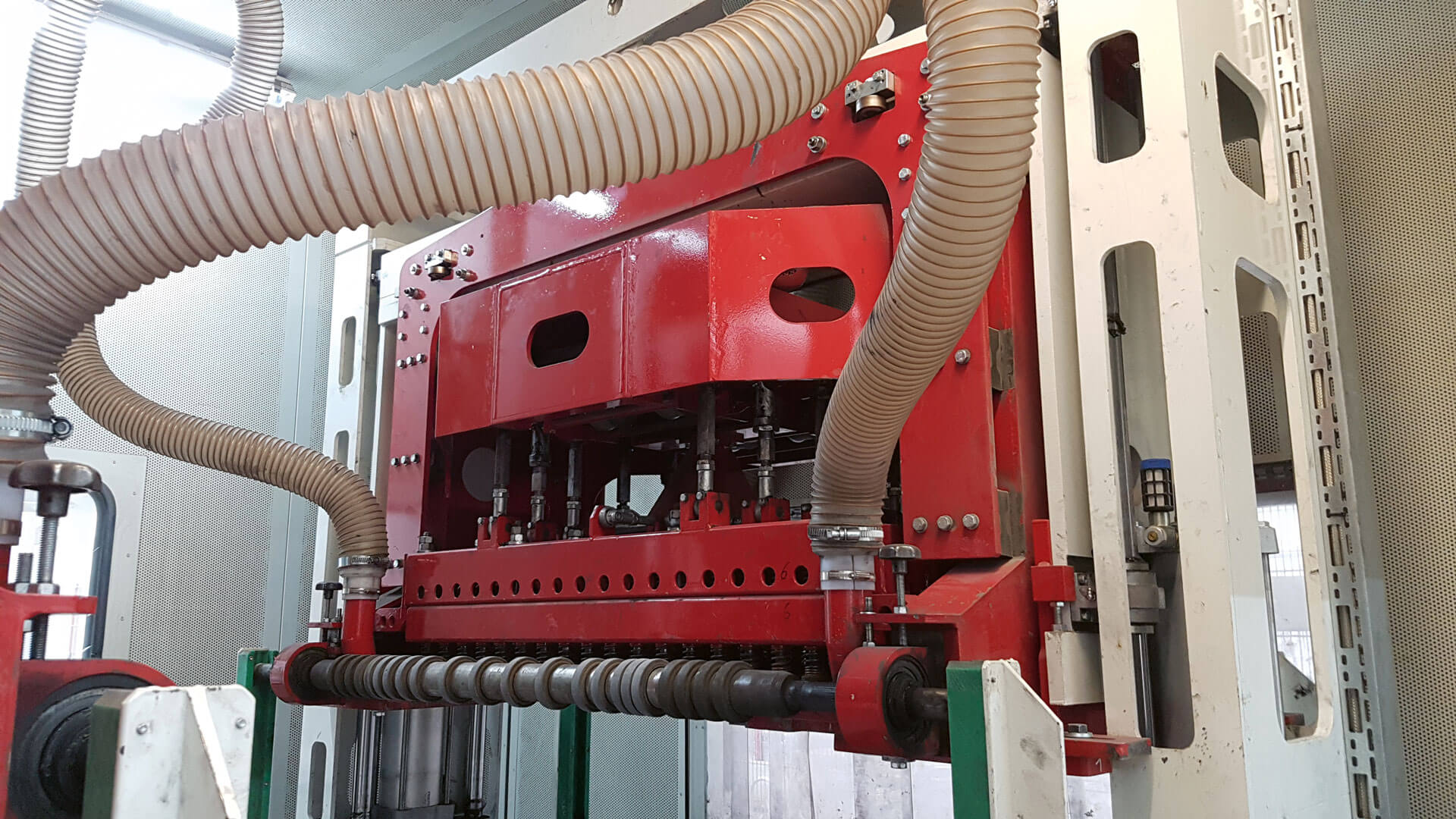

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.