Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Curlen

Customer benefits

- Cost saving due to individual replacement of worn brush segments

- Durable machine due to stable and high-quality construction

- Time saving and ease of use due to fully-automated contact pressure control

- Easy training of the operating personnel due to simple operation

- Cost and space saving due to elimina- tion of water recycling (no water treatment) and special waste disposal

- Cost saving due to reusing the dust (depending on the dust extraction used) as filler in the concrete mixture

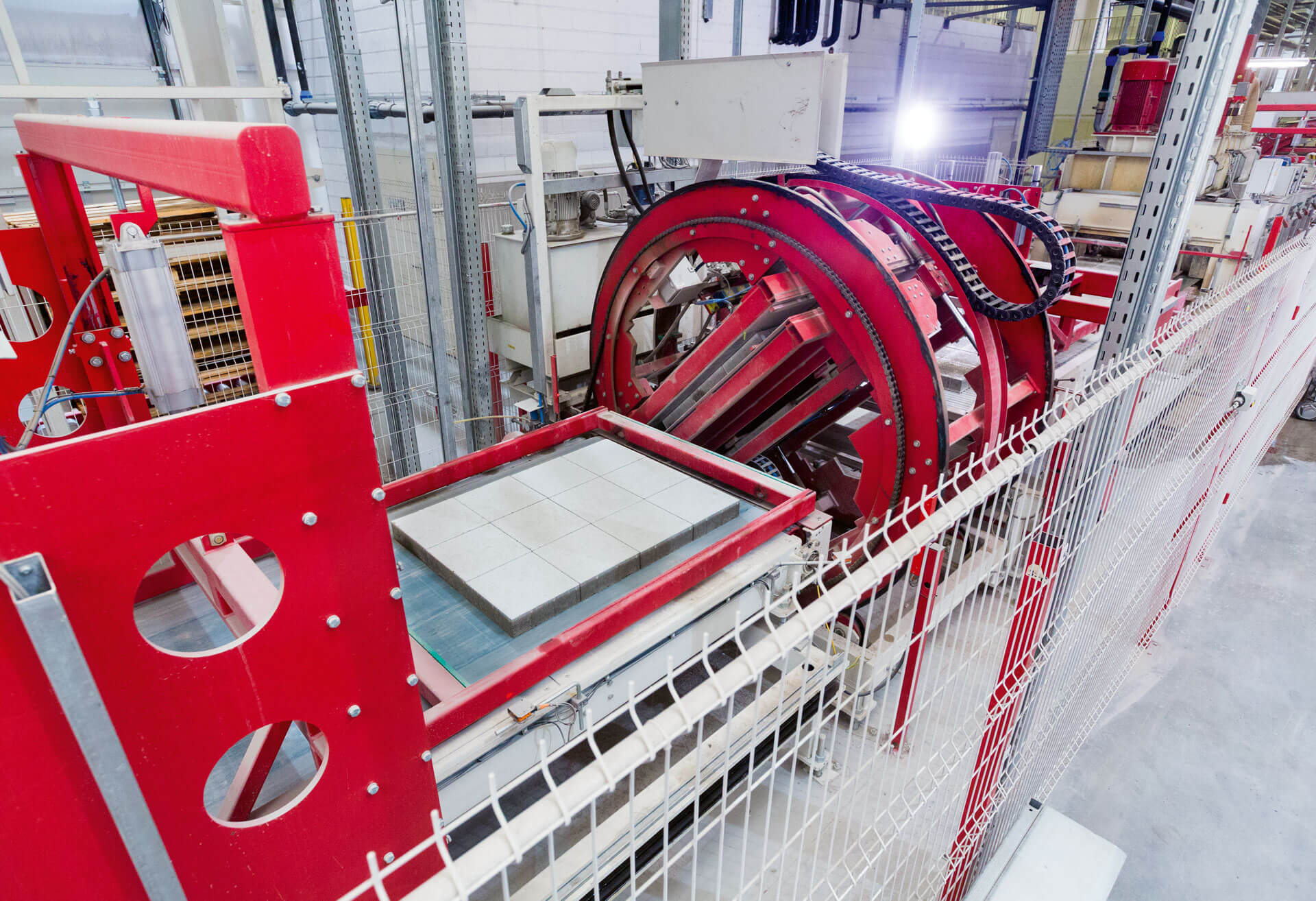

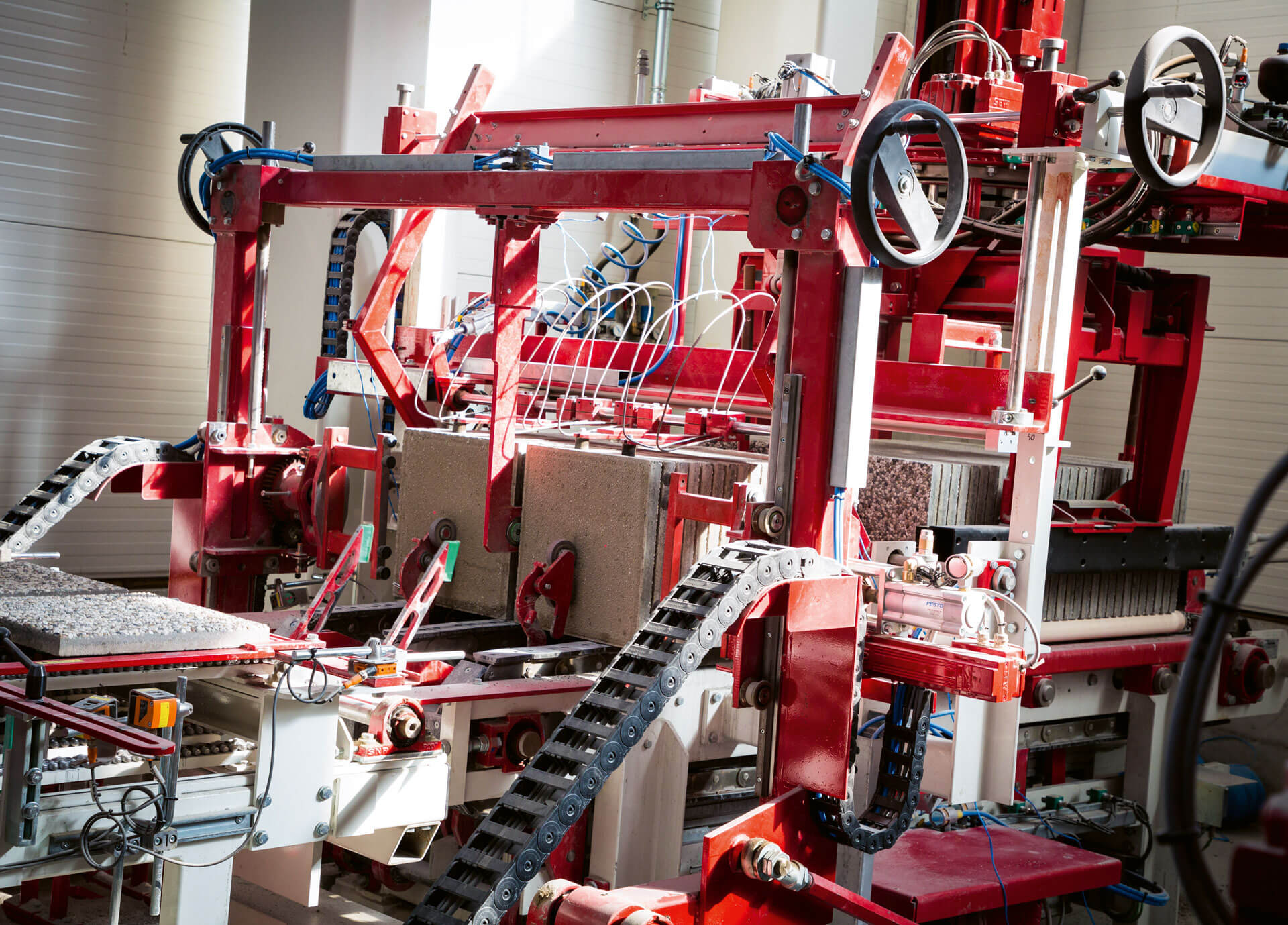

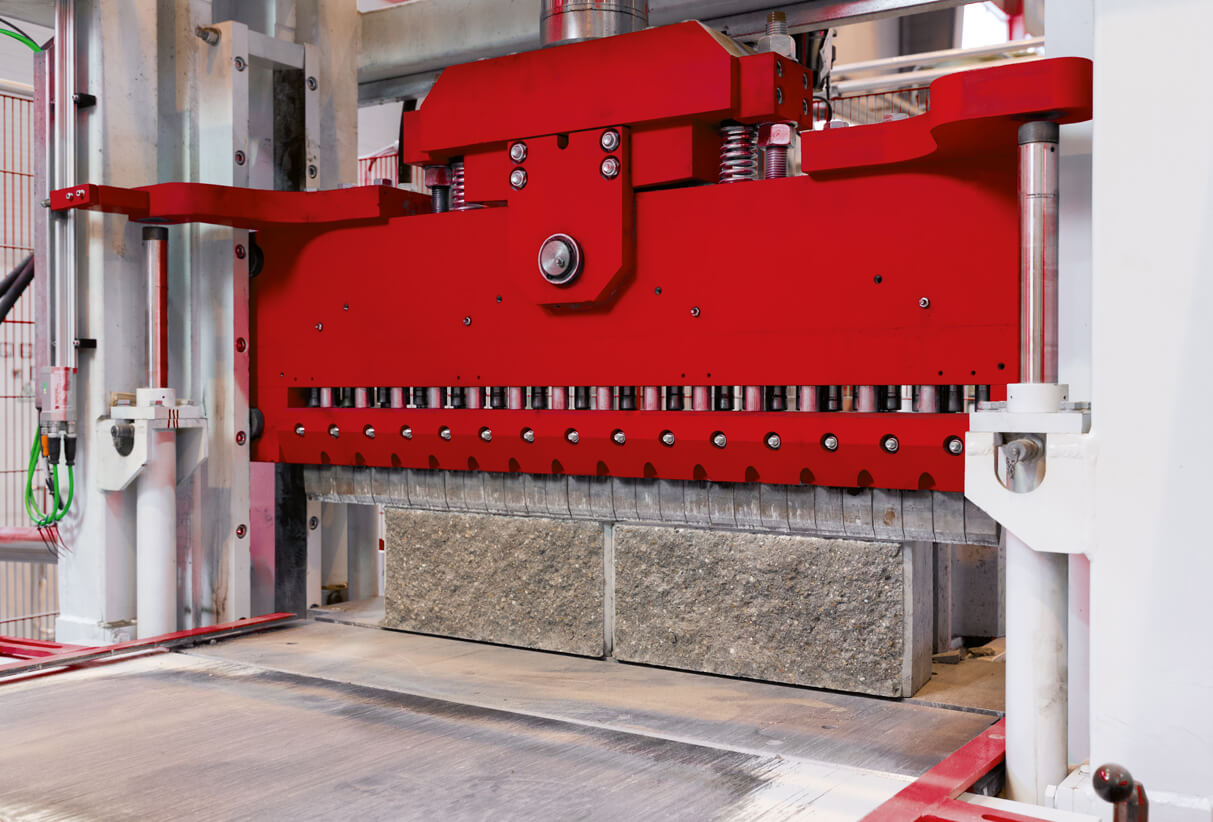

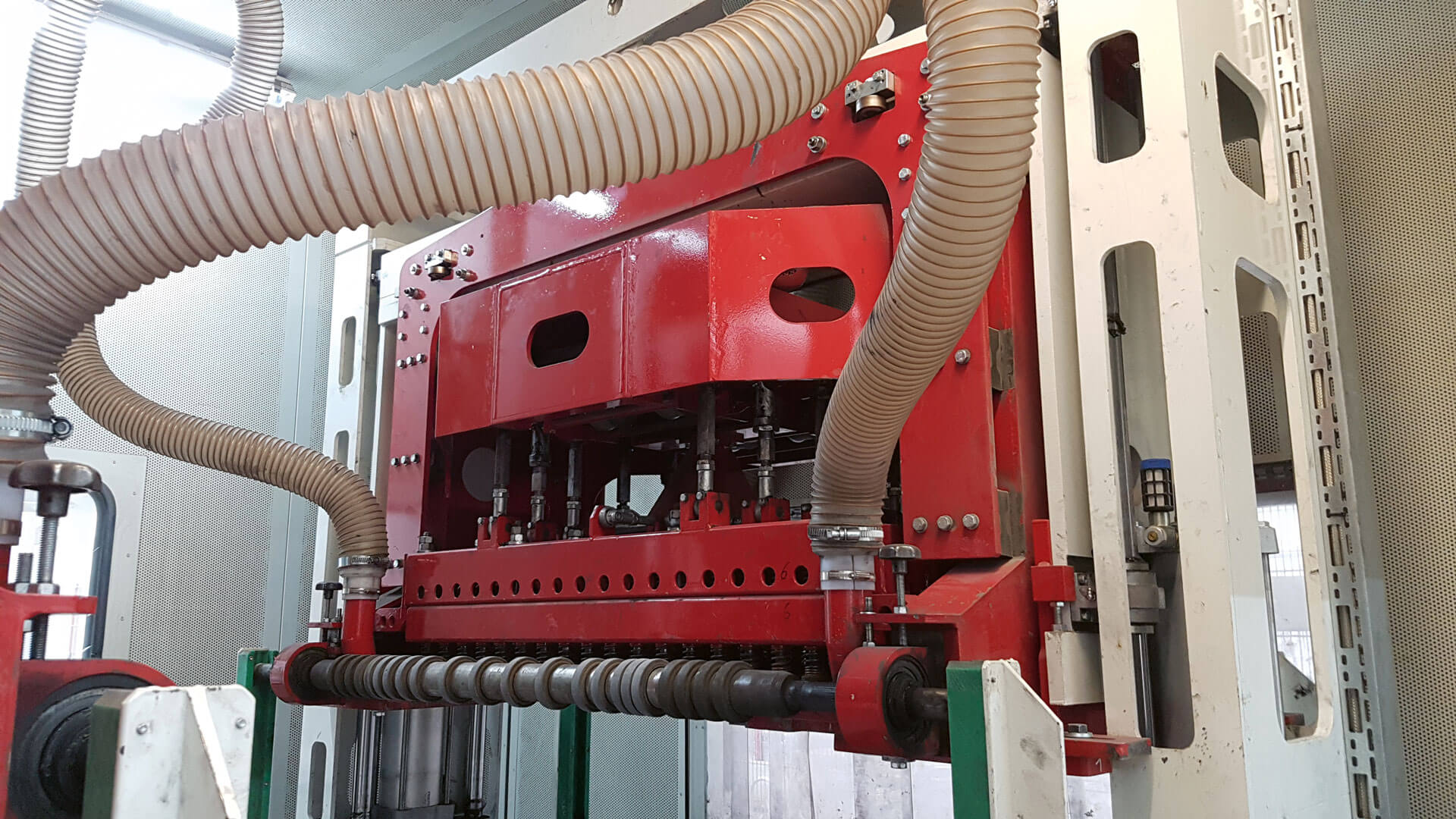

Of pavers and slabs by means of rotating brushes . Paver layers and/or slabs are transported in endless row on a belt conveyor through the machine consisting of 2 tunnels. Each tunnel is equipped with 2–4 brushes, depending on the version (in total 4–8 brushes). Brushes have different brush strengths and are arranged in the machine from rough to fine. Brushes are arranged in inclined execution. Brushes 1, 3, 5 rotate in the opposite direction to brushes 2, 4, 6. This counter rotation and the mirror-inverted inclination avoid brush marks on the product surface.

Curling is particularly well suited for textured products but gives also slight shine and a tangibly smooth and silky surface to roughly ground and/or shotblasted products. By removal of surplus cement, the aggregates are carved out and polished. This makes the product surfaces dirt- and moisture-repellent and non-slip.

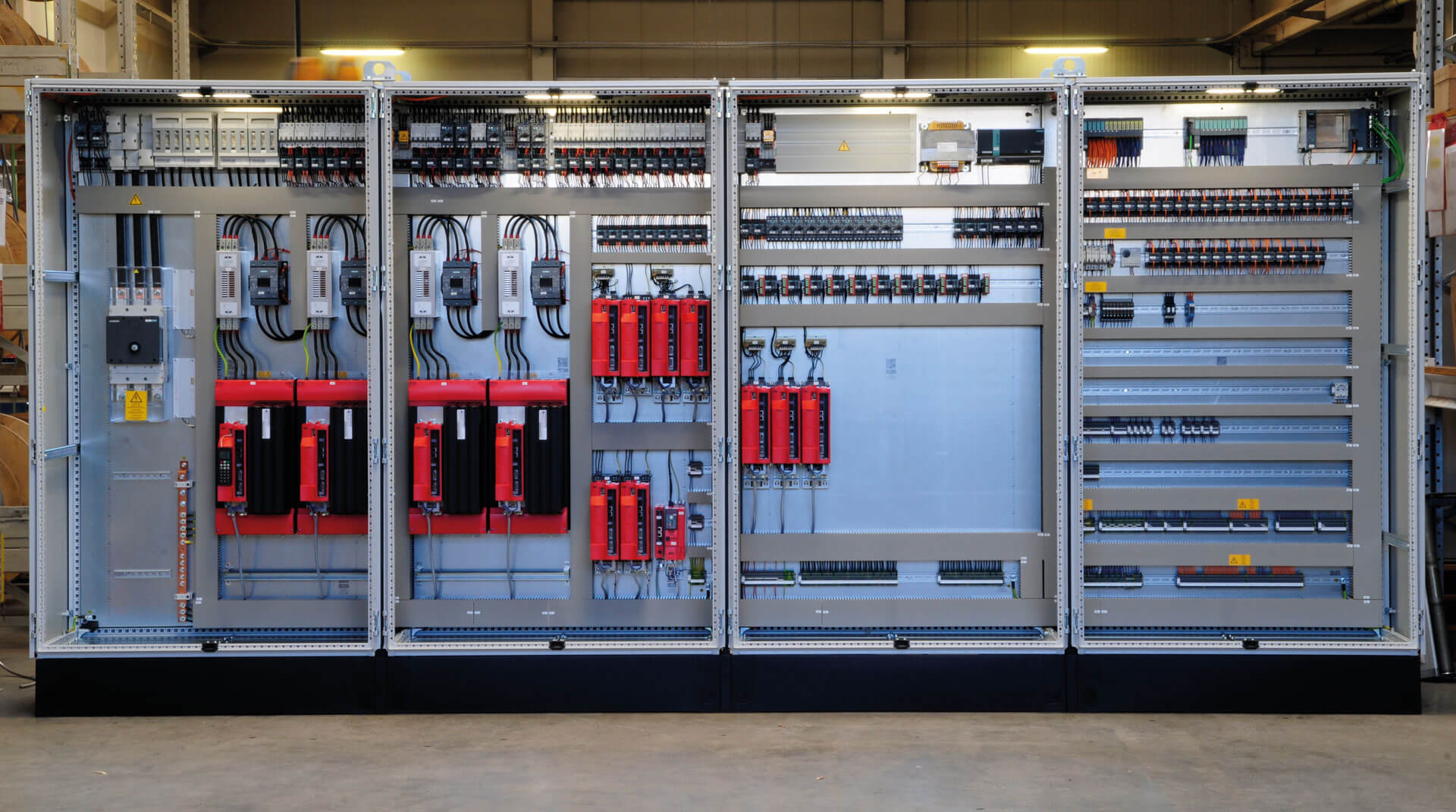

Treatment in dry mode. Deliverable with cartridge or sinter-lamella filter. Available working widths 850 and 1,200 mm.The brushes are divided in segments which can be individually replaced upon wear. Frequency-controlled main drives and vertical movement. With contact pressure control. The machines are equipped with an independent control and operation panel with visualization. All processing parameters can be saved for every individual product type. Available as offline machine, integrated in value adding lines or as a bypass of the stone making machine. Can be combined with rough grinding, shotblasting, aging, impregnation and coating.

Technical specifications *

| Belt speed | 1 – 10 m / Min. |

| Average processing speed | approx. 3 - 4 lin. m / Min. |

| * depending on product characteristics and required final result | |

TECHNICAL DATA

Product thickness: 20–350 mm

Working width: 850 mm/1,200 mm

| Model | 850 | 1200 |

| Length | approx. 7,500 mm | approx. 8,000 mm |

| Width | approx. 2,500 mm | approx. 2,800 mm |

| Height | approx. 3,000 mm | approx. 3,200 mm |

| Total connected load (2-/4-/6-times) | 35/68/100 kW | 50/95/140 kW |

| Exhaust air (2-/4-/6-times) | 4,500/6,000/9,600 m3/h | 6,000/9,600/12,000 m3/h |

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.