Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Shotblasting

Customer benefits

- Sustainability and fast amortization due to modular expansion stages

- Easy integration into existing systems due to flexible design and control

- Durable machine due to stable and high-quality construction

- Long service life and cost saving by using hardened tool steel for the wear parts of the turbines

- Easy training of the operating personnel due to simple operation

- Space saving due to integrated filter system

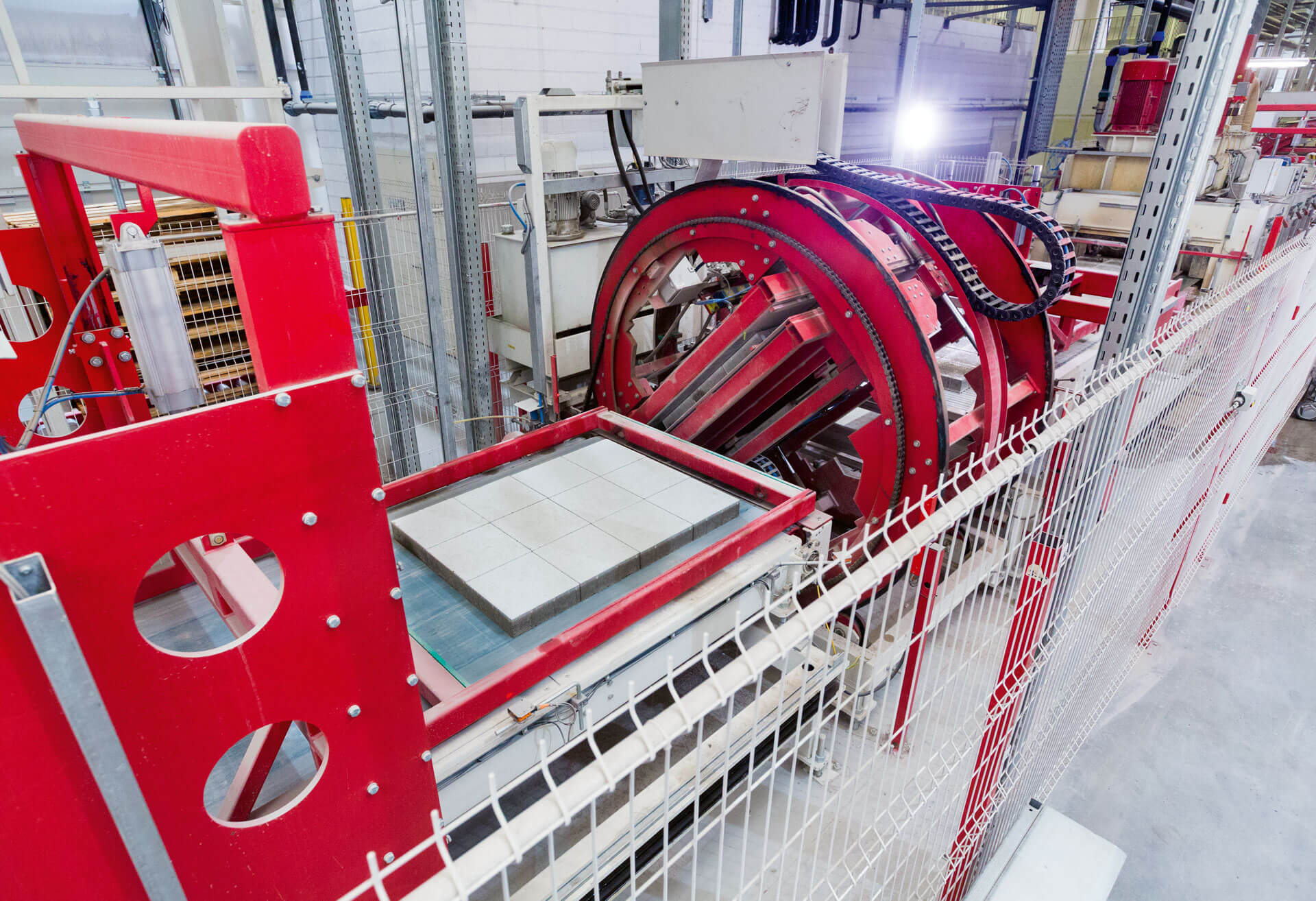

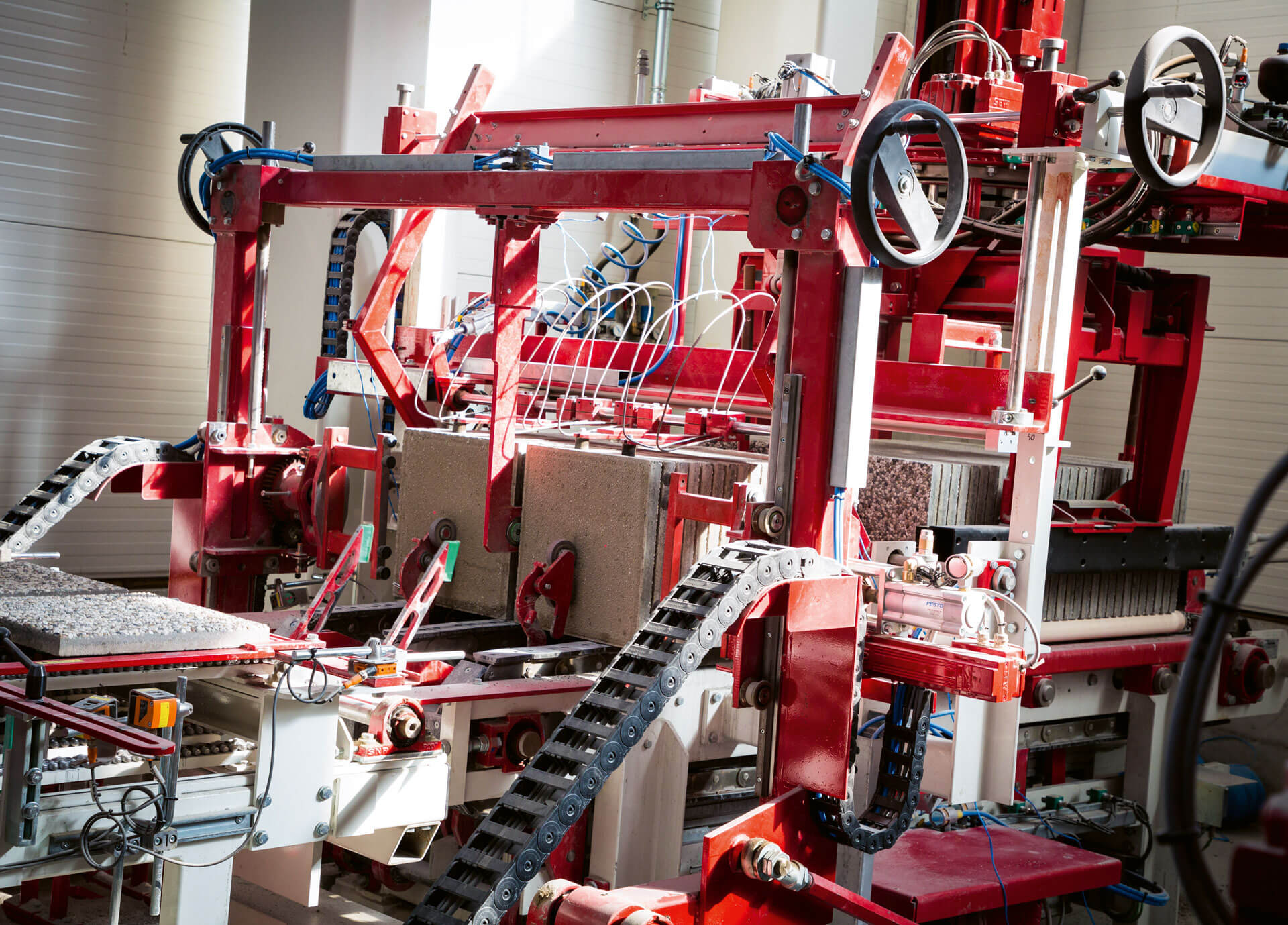

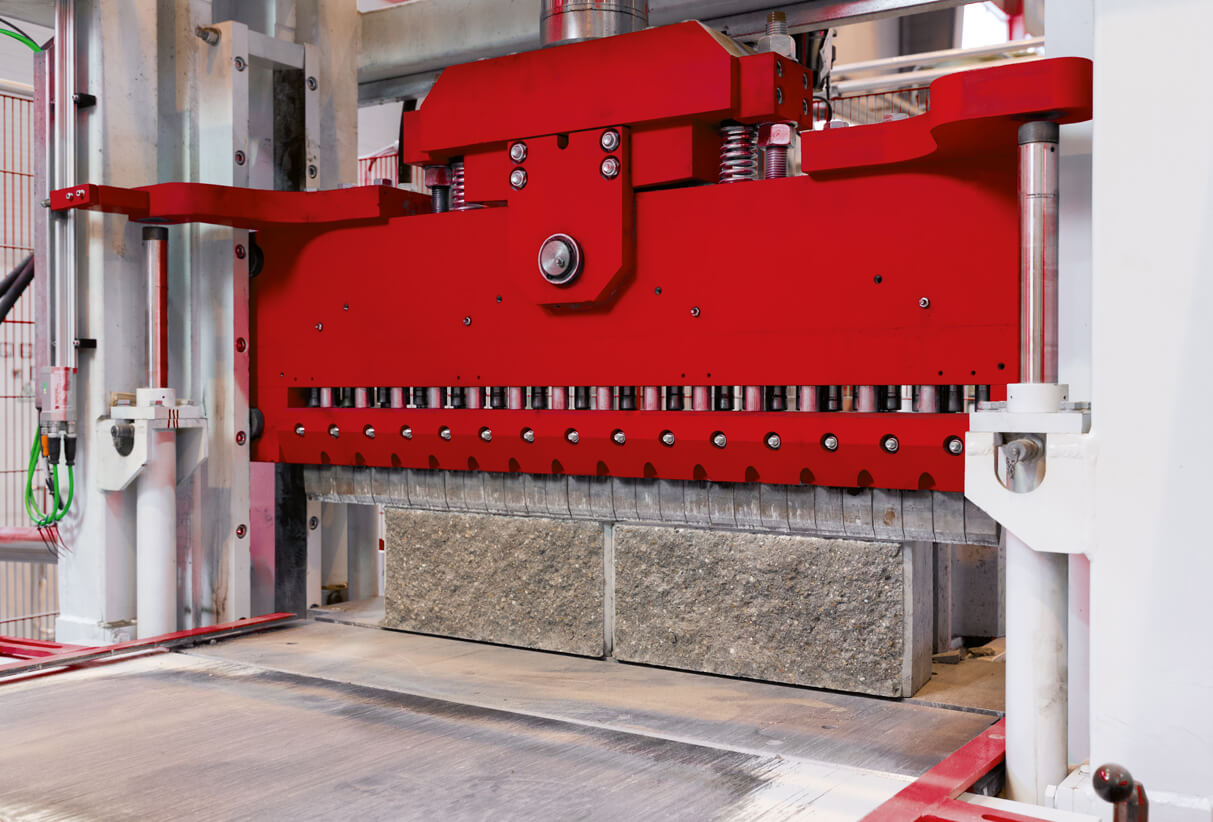

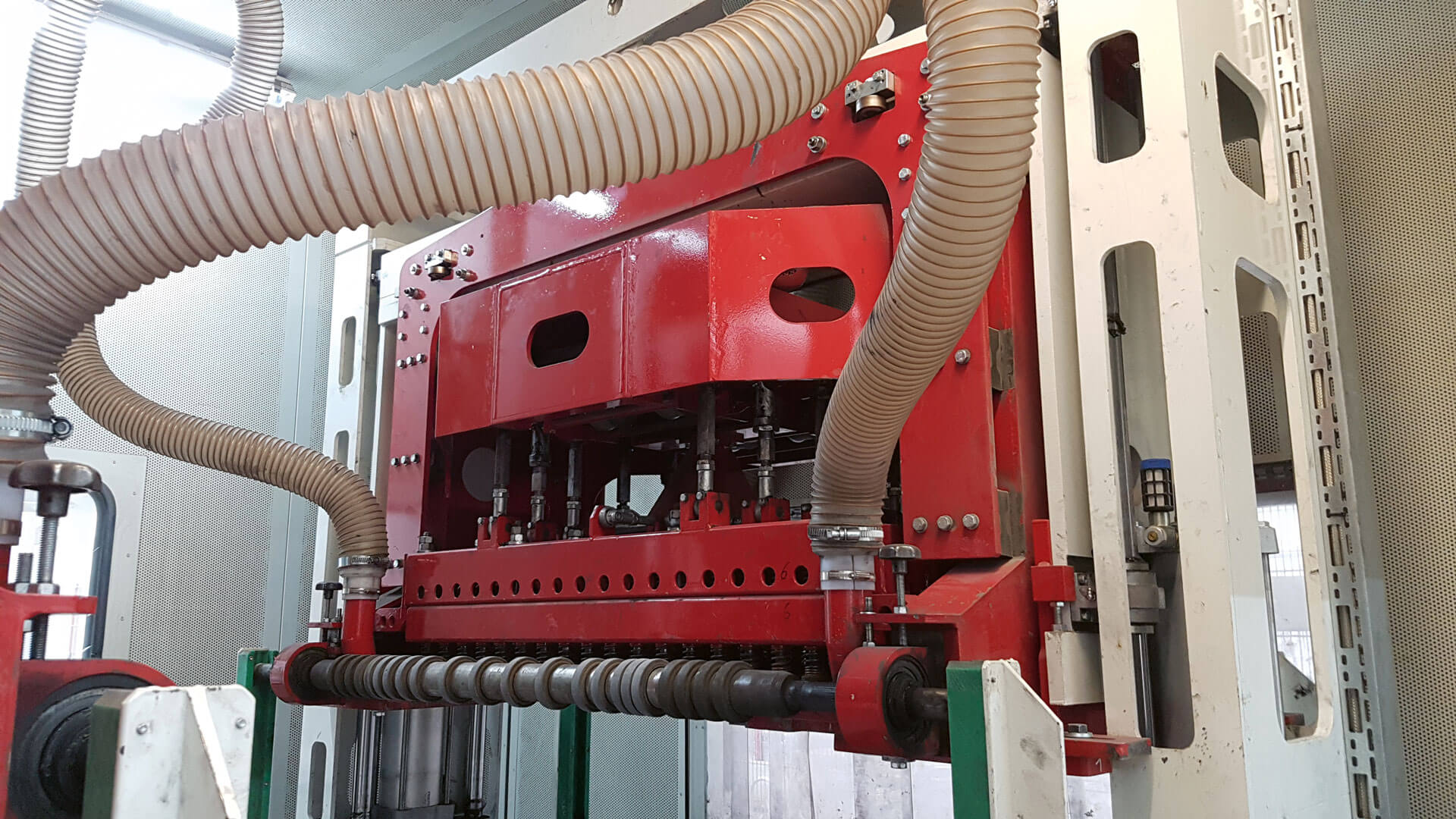

Of pavers, slabs, curbstones, block steps – optionally face and/or side surfaces. During processing, cement is removed and the aggregates are exposed. Shotblasting machines use steel or stainless steel balls as abrasives. In operation, the steel or stainless steel balls, standard size 0.6–0.8 mm, get thrown by means of 2–4 turbines at the products to be shotblasted . Depending on infeed and outfeed situation, processing is done cyclewise or in a flow . Blasting speed and belt speed are adjustable in relation to the product to be treated and the desired surface appearance . Turbine and belt drive are frequency-controlled for a homogeneous treatment from rough to fine. The quantity of abrasive is electro-pneumatically adjustable.

The perforated belt, ribbed transversely to the running direction, ensures a proper transport of the layers without drifting of single stones and refeed of abrasive

material to the material silo. Abrasive material which stays on the shotblasted products is removed by a height-adjustable high pressure blowing device or a magnetic strip and fed back to the material silo.

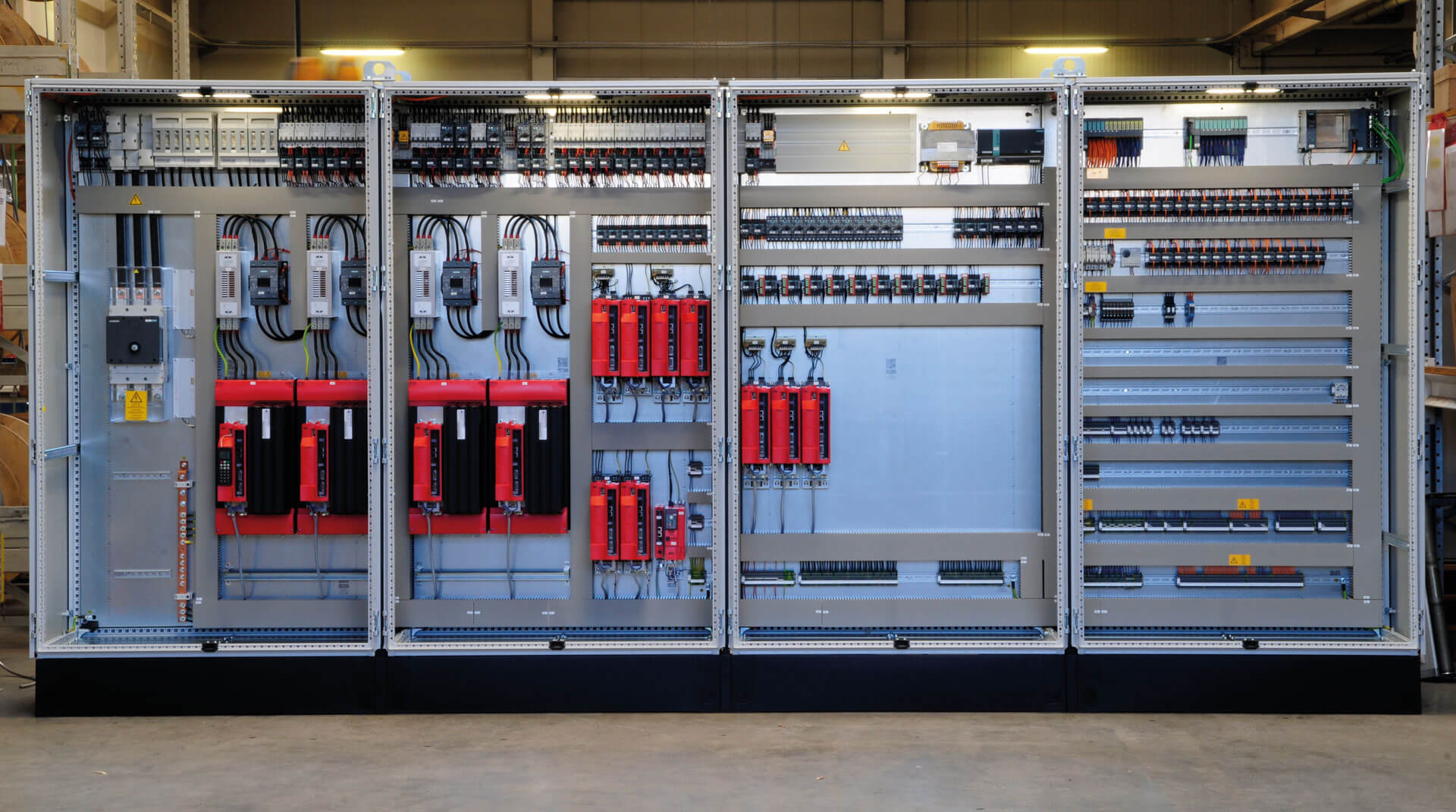

Blasting chamber and turbine housing made of manganese steel. Available working widths 850 and 1,200 mm. A cartridge filter unit is installed as standard on the shotblasting machine. The machines are equipped with an independent electro-pneumatic control and operation panel. Available as stand-alone machine, integrated in value adding lines or as a bypass

of the stone making machine. Shotblasting can be combined with all surface value adding processes.

Technical specifications *

| Belt speed | 2,5 – 11 m / Min. |

| Average processing speed | approx. 5 lin. m / Min. |

| * depending on product characteristics and required final result | |

TECHNICAL DATA

Product thickness: 20–400 mm

Working width: 800 mm/1,200 mm

| Model | 850 | 1250 |

| Abrasive consumption | 150 kg/Min. per turbine | 240 kg/Min. per turbine |

| Electric power | approx. 49 kW | approx. 74 kW |

| Compressed air for filter and control | 22 m3/h at 6 bar | 36 m3/h at 6 bar |

| Noise level | < 90 db(A) | < 90 db(A) |

| Filter capacity/power | approx. 6,000 m3/h | approx. 9,600 m3/h |

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.