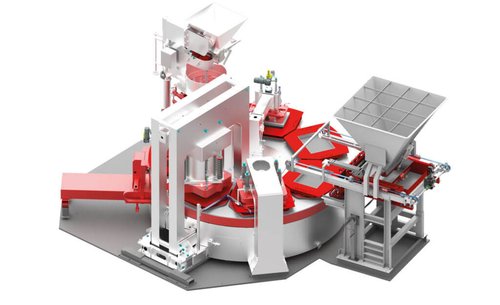

Hermetic press by SR SCHINDLER

Increase your earnings with our hermetic presses. Innovative. Reliable. Efficient.

UNI hermetic presses for the manufacturing of double-layer square and rectangular high-quality and dense slabs. Terrace slabs and flagstones, as well as large-sized slabs for use in public places and buildings (train stations, airports, shopping centers, etc.). Thin, single layer slabs can also be produced for interior spaces and building cladding through the expansions with filter press technology. Thanks to the surface density, hermetic slabs are suitable for designing high-quality floor and wall surfaces in indoor and outdoor spaces. A wide range of products can be created by using various face mix materials and surface treatment processes.

Design features

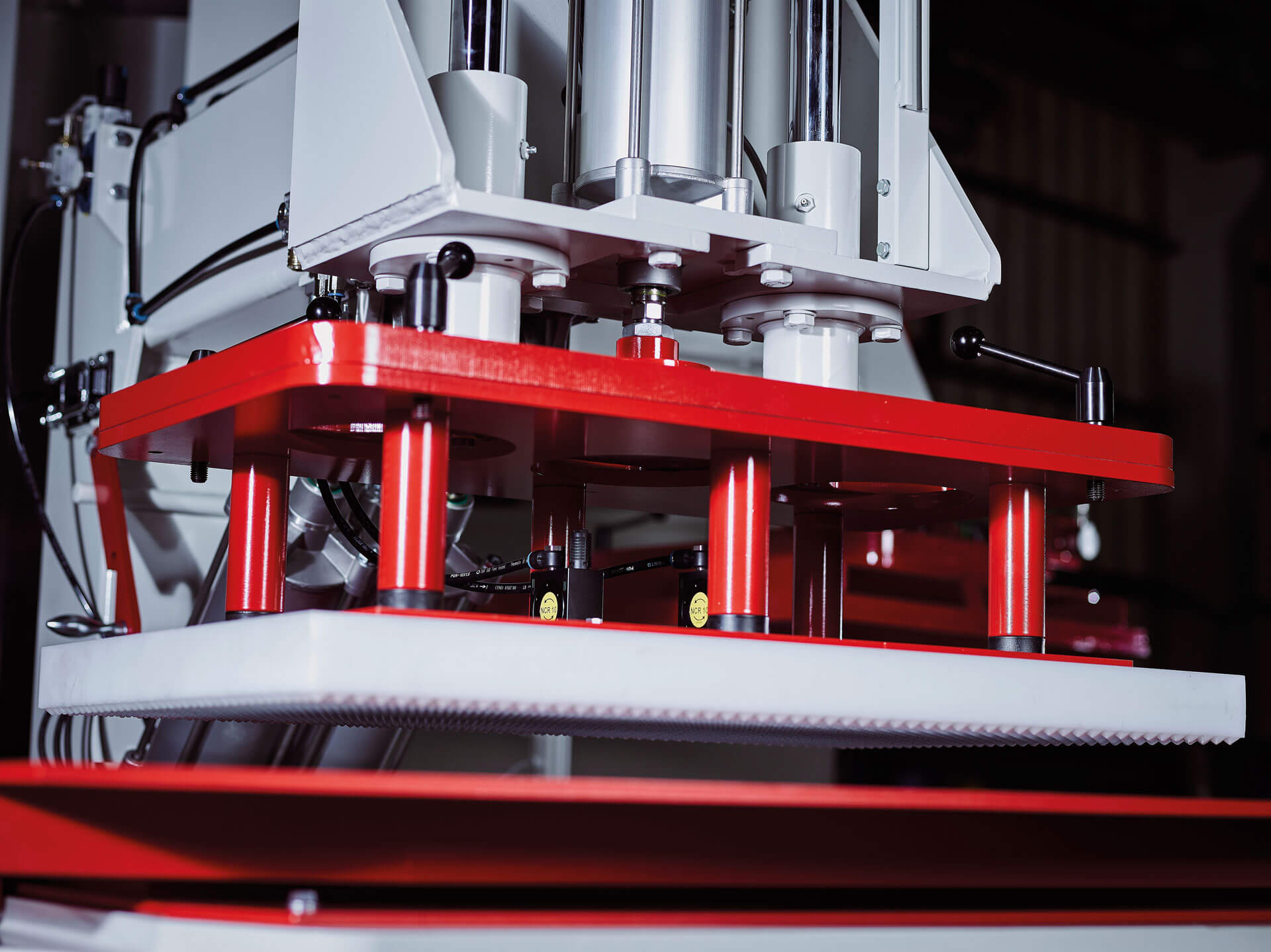

- Integrated 7 station concept with pre-press and main press station

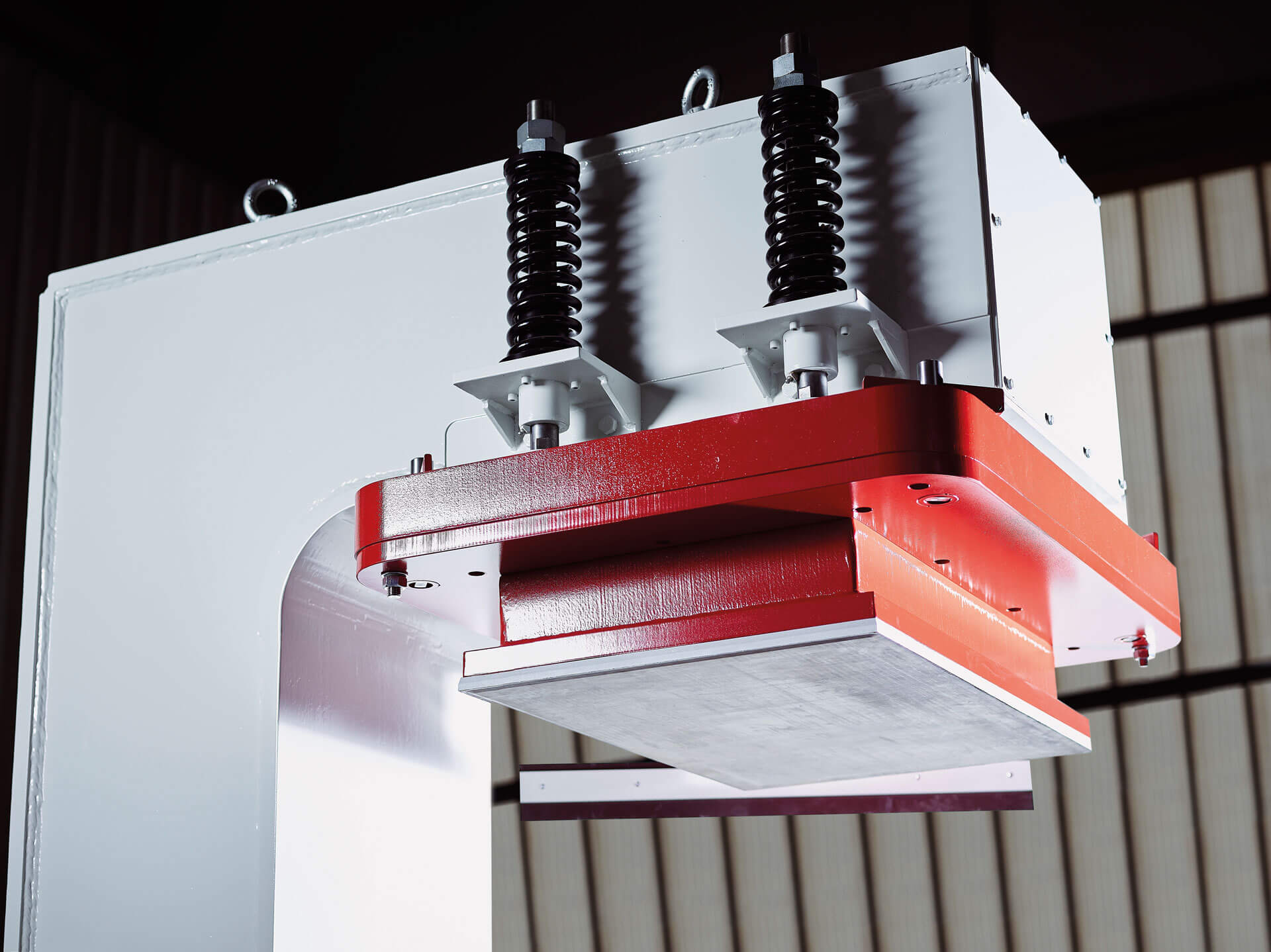

- Massive portal design for optimum absorption of the press forces

- Controlled servo-hydraulic pump for the press pressure

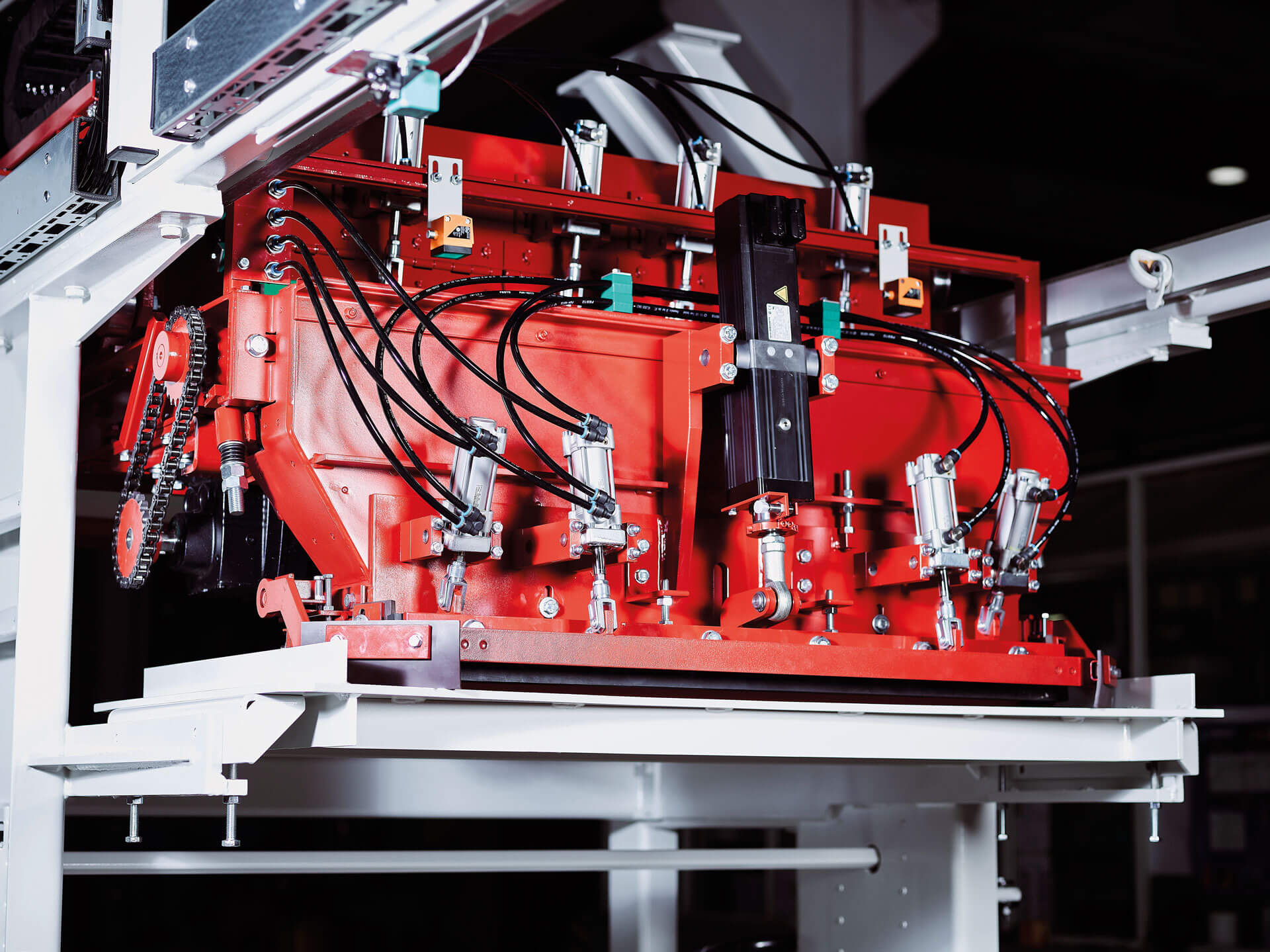

- Turntable on the internal toothed rotating assembly, stored safely within the machine, including automatic lubrication

- Controlled servo turntable drive

- Compressed air supply for the 7 stations via air docking system for reliable function of the mold lift cylinder

- All parts are made from high-quality rolled steel

- All 7 stations are equipped with frequency-controlled vibrators

- Control and visualization from the newest generation (Siemens Simatic S7-1500)

- All electrical control devices integrated safely in the water and dust resistant control panel

- Functional safety concept

Technical specifications *

| Average cycle times depending on the product format and press type | approx. 12-22 sec. |

| * depending on the product properties and the desired end result for double-layer slabs | |

Advantages of UNI hermetic presses

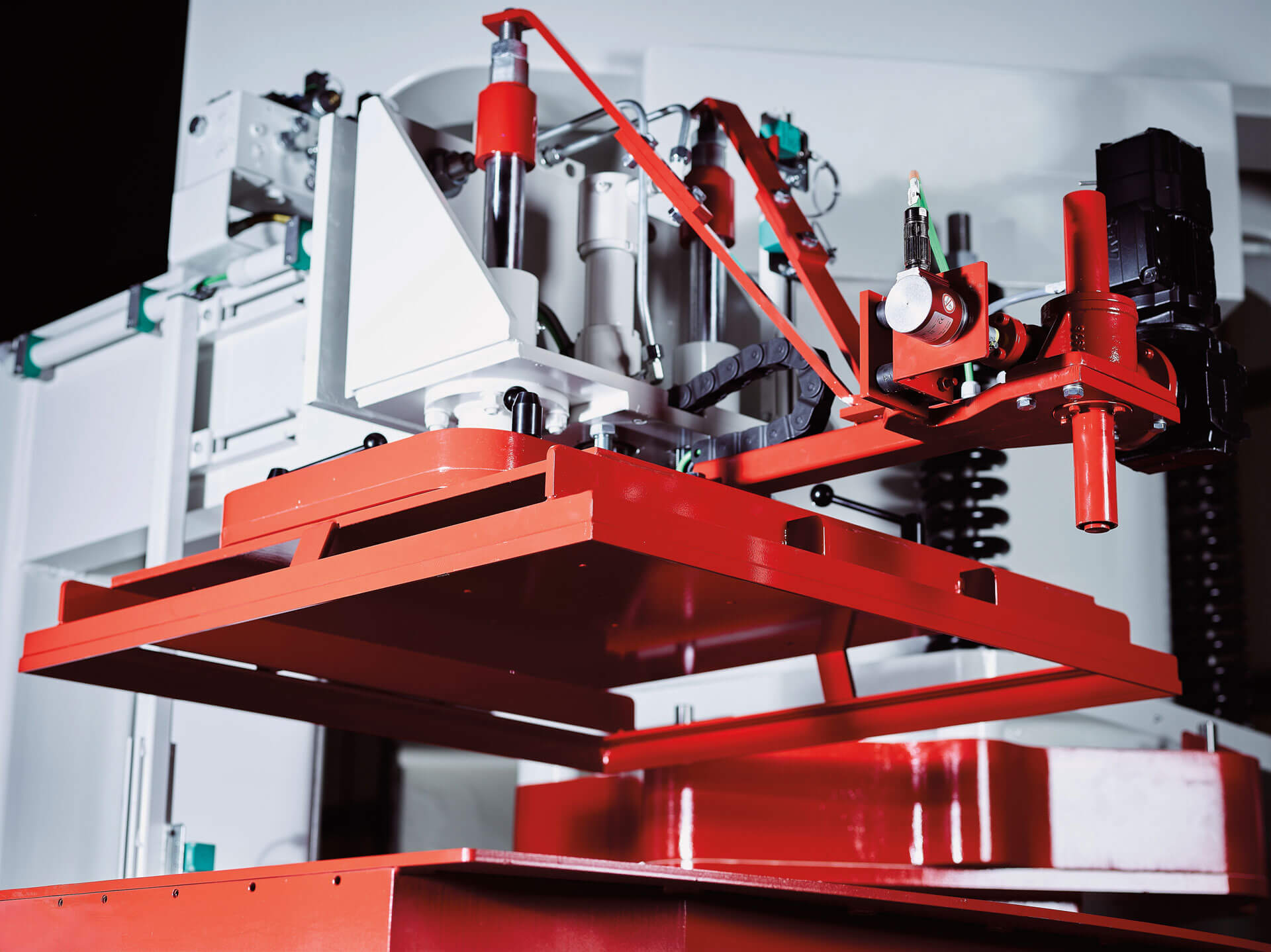

- Optimal access for maintenance, mold change and operation through the 7 station concept

- 6 or 7 station concept

- Improvement of the accessibility through the portal design

- Optimized cycle times through controlled servo turntable drive

- Protection of the drive unit through the enclosed turntable version and good access to the drive unit via the press table

- Early detection of wear of the ultra bushings between the press piece and anvil through electronic air gap monitoring, resulting in improved scheduling of service intervals and reduction of unscheduled downtimes

- Cleaning or maintenance tasks largely independent of the operation of the press thanks to the quick-change system (Plug-In) for 2 dosers

- Optimum mold filling and recirculation of the excess material into the process through the back mix feeder (patented for Germany)

- Process optimization through the selection of different face mix distribution systems

- Increase in energy efficiency thanks to the highly dynamic servo-hydraulics

- Simplification of the preventative maintenance without stopping the press due to unrestricted access to the central pneumatic valve cabinet on the frame of the main press

- High system availability thanks to the visualized operator interface and malfunction analysis

- Products can be produced with any type of surface structure, with chamfers and spacers as well as tactile slabs

| Press | UNI 600/7 | UNI 1200/7 | UNI 1200/6 | UNI 1200 plus/6 |

| Number of stations | 7 | 7 | 6 | 6 |

| Max. slab formats 1-fold [mm] | 600 x 600 | (1,000 x 1,000 bei Belegung mit 3 Formen) 800 x 800 900 x 600 1000 x 500 | 1,000 x 1,000 | 1,200 x 800 1,000 x 1,000 |

| Max. slab formats 2-fold [mm] | 600 x 400 | 500 x 500 | 500 x 500 | 600 x 600 |

| Max. slab formats 4-fold [mm] | 300 x 300 | 400 x 400 | 450 x 450 | 450 x 450 |

| Turntable diameter | 3,900 mm | 4,700 mm | 4,700 mm | 4,700 mm |

| Distance mold frame lifting cylinder | 1,090 mm | 1,275 mm | 1,275 mm | 1,475 mm |

| Min. slab thickness | Depending on slab size, up to format 400x400 min. 35 mm, for bigger formats individual according material properties | |||

| Max. slab thickness | 80 mm | 100 mm | 100 mm | 100 mm |

| Max. pressure of main press-station | 600 t | 1,200 t | 1,200 t | 1,200 t |

| Piston diameter of main press station | 540 mm | 770 mm | 770 mm | 770 mm |

| Weight of the machine incl. 1 set of moulds | approx. 30,000 kg | approx. 65,000 kg | approx. 65,000 kg | approx. 65,000 kg |

| Power consumption | 68 KW | 95 kW | 95 kW | 95 kW |

| Cycle time range | 13 - 14 s | 15 - 20 s | 16 - 25 s | 16 - 25 s |

| Length x width x height | 4.8 x 4.0 x 3.2m | 6.0 x 5.0 x 4.0 m | 6.0 x 5.0 x 4.0 | 6.0 x 5.0 x 4.0 |