Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Handling and curing

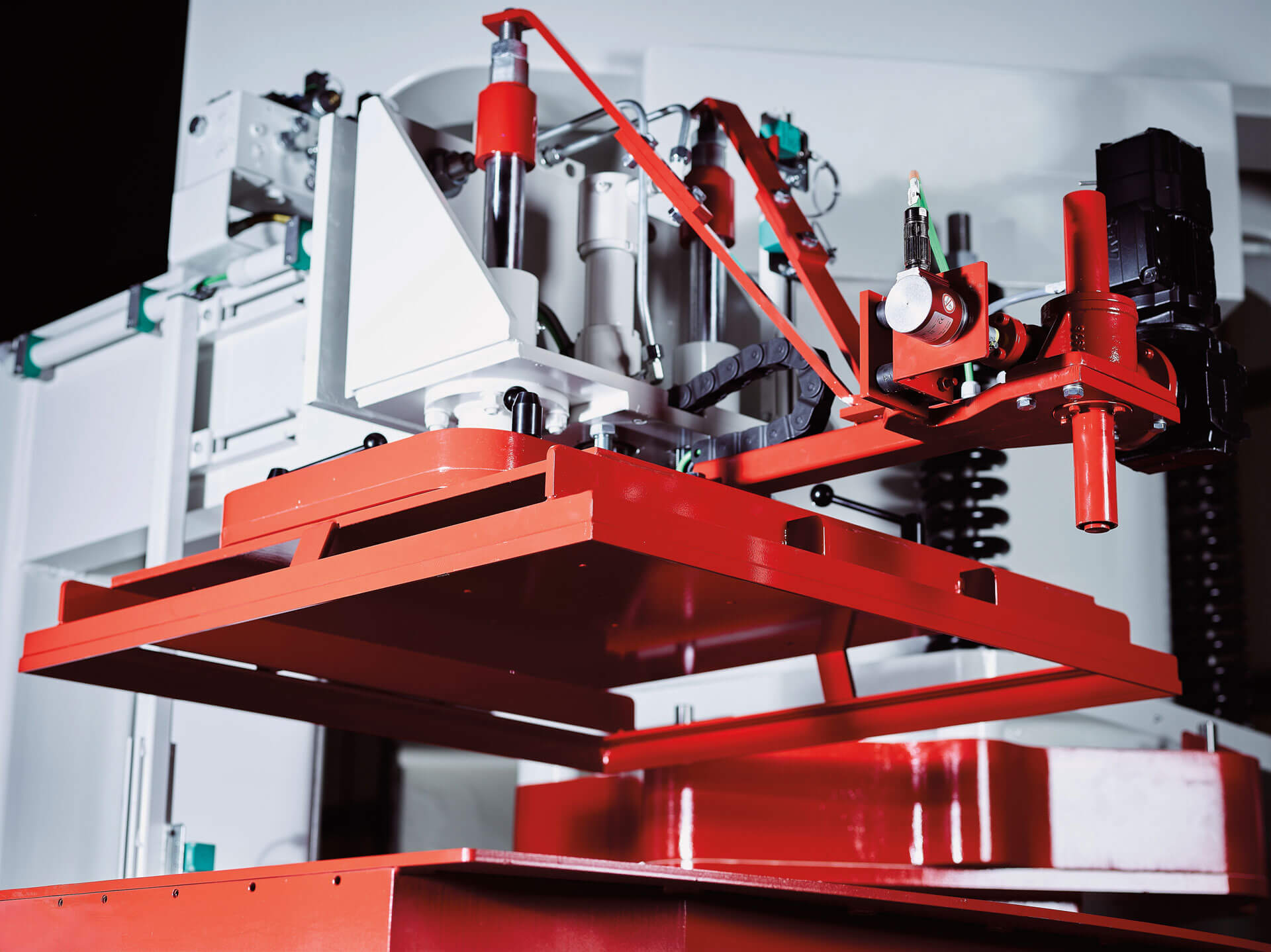

Green slab turning device

- To remove the slabs from the slab depositing carriage by means of a vacuum lifter for 180° turning and for delivery to the slab transfer device of the flat depositing device-wet side

- Consisting of a solid frame, servomotor turning arm and a lifting unit with interchangeable suction units depending on the slab formats

- Quick adjustment to product height by servomotor lifting movement of the suction frame

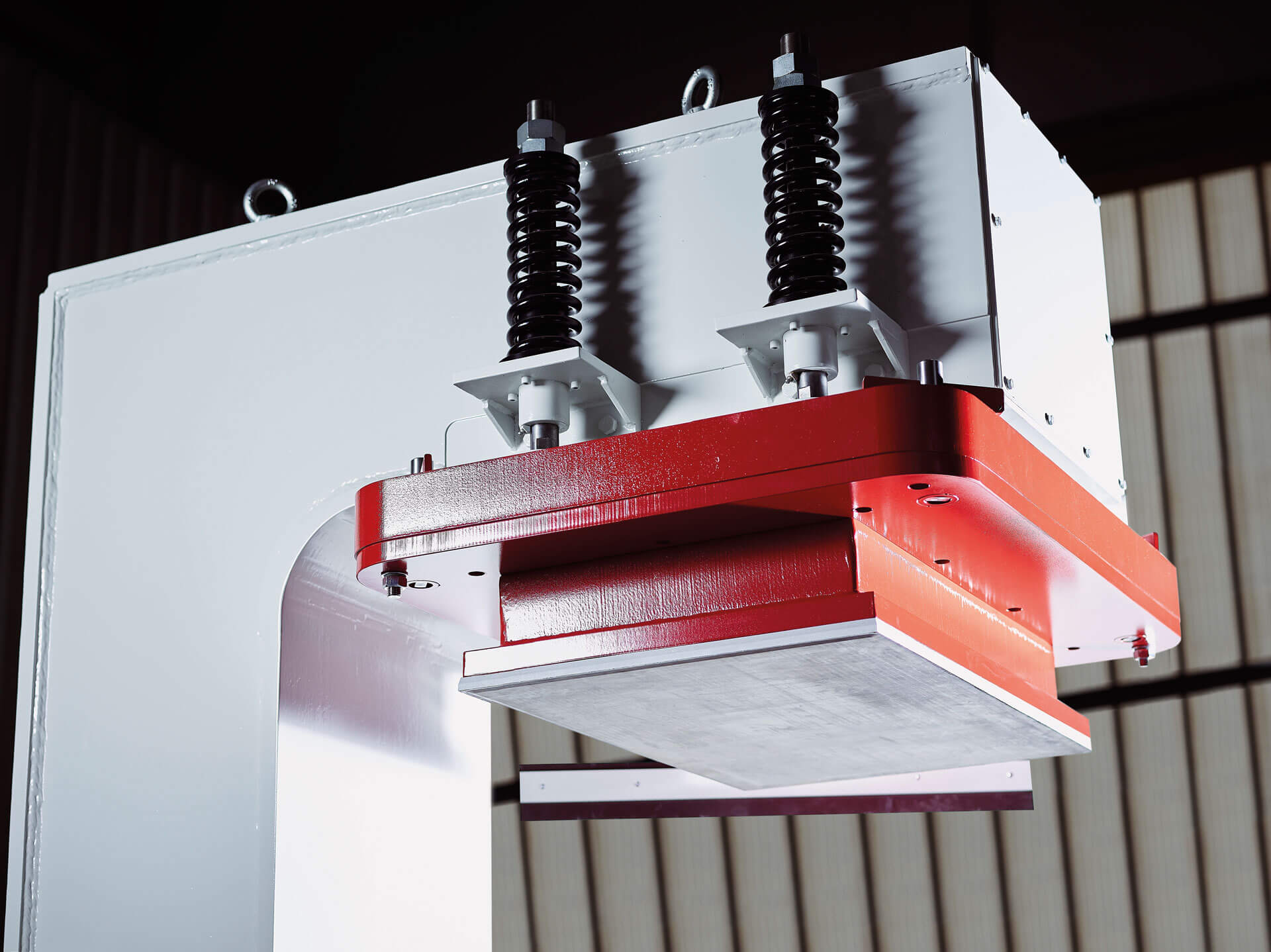

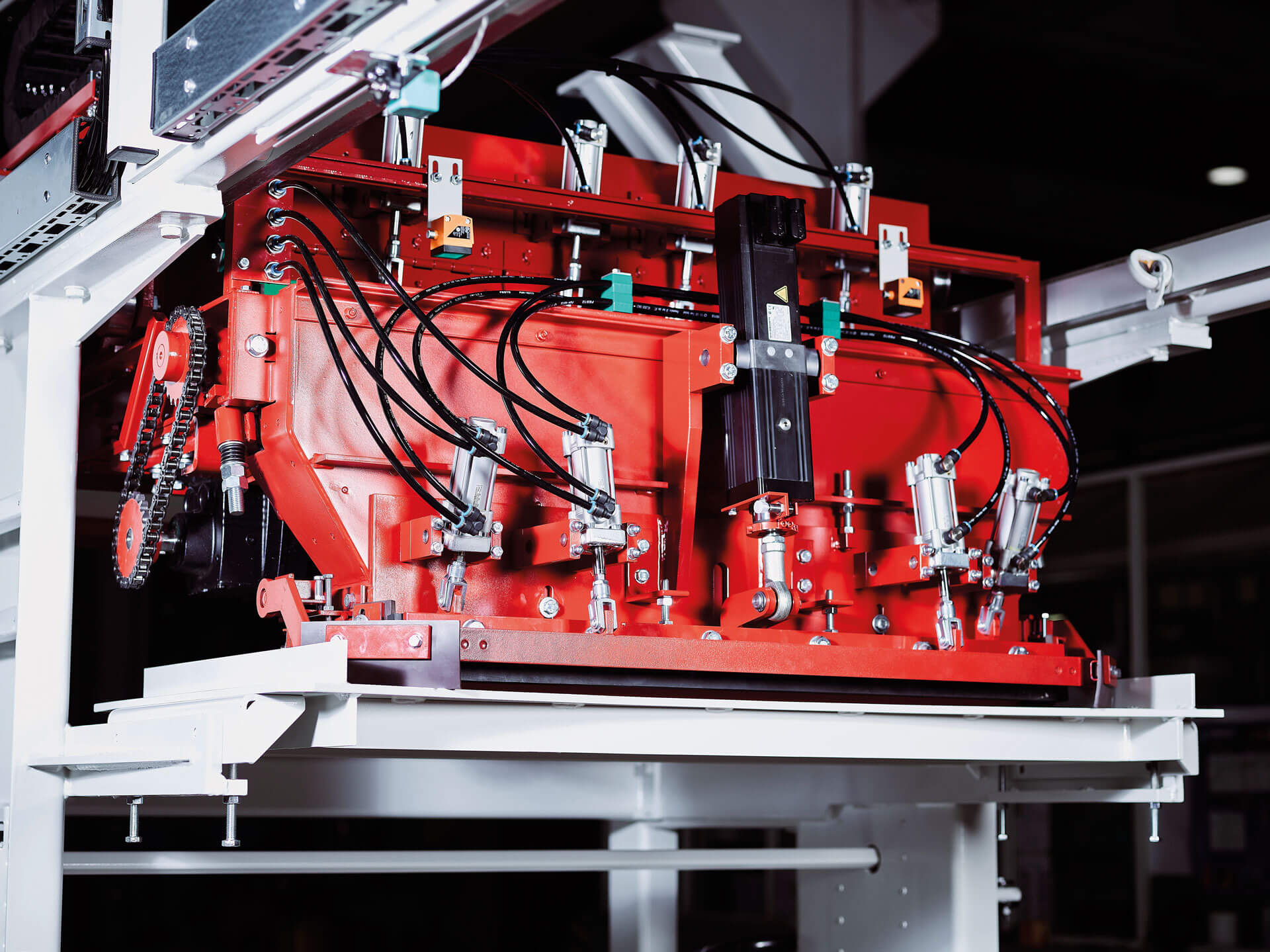

Slab transfer devices

- Slab transfer device-wet side picks up the products from the carriage or from the green slab turning device and passes them to the following flat depositing device-wet side

- Universal slab transfer device-dry side takes the products from the flat depositing device-dry side and passes them to

the value adding line or packing line - Consist of electrically driven horizontal slides, lifting mast and turning device and format-dependent suction units on

the wet side and a universal vacuum suction plate for all formats on the dry side, with vacuum generator - Travel, lifting and rotary drives designed as servomotors

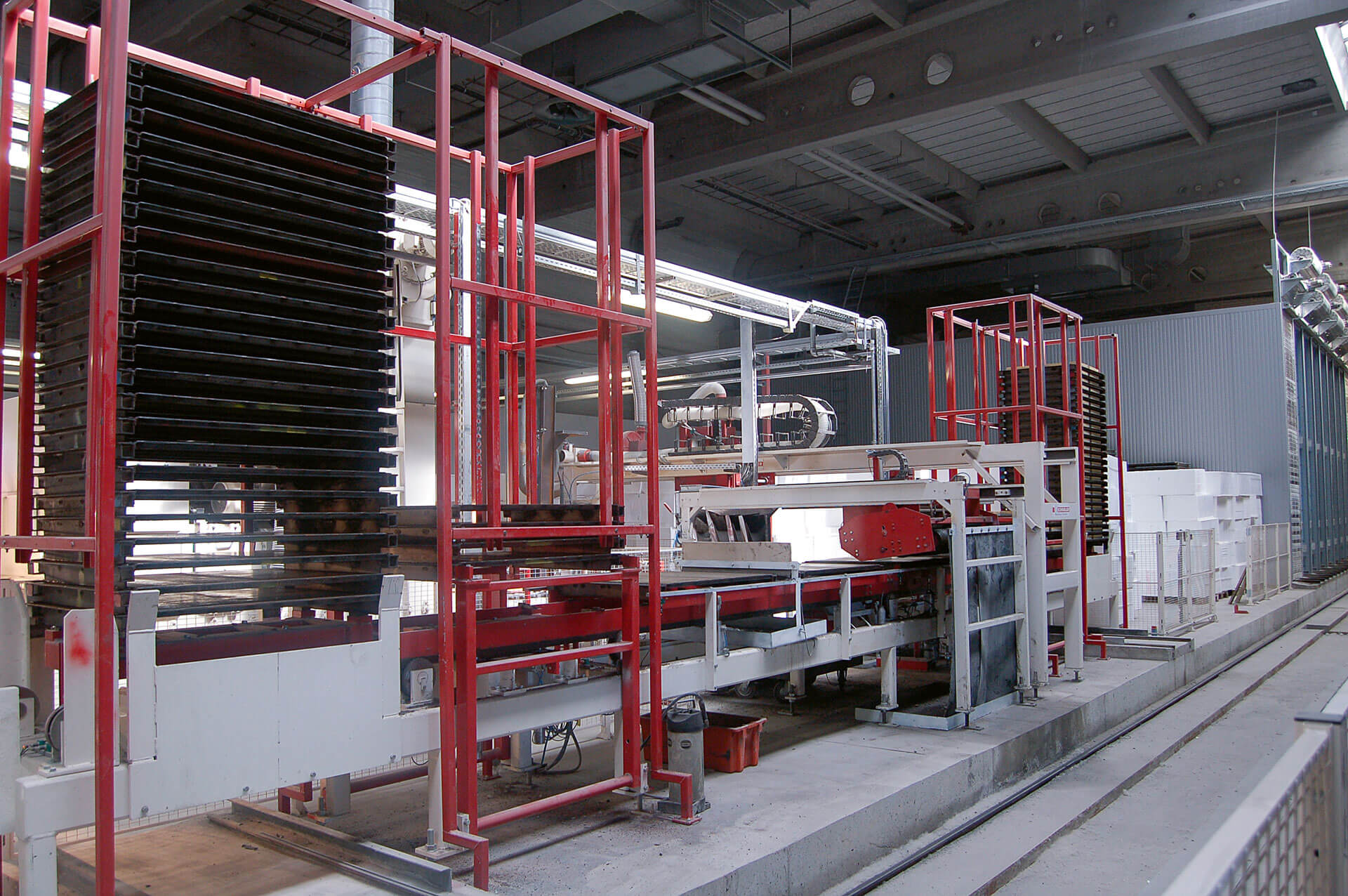

Finger car

- For transporting the filled pallet stacks with green slabs to the shelf spaces, the empty pallet stack to the flat depositing device-wet side and the pallet stack with cured slabs to the flat depositing devicedry side, and for transporting the empty pallets from there to the press or shelf

- Fully automatic, including control. The system is designed so that two pallet stacks can be positioned one above the other in the shelf spaces

- Upper carriage designed with 180° turning device so that the loading and unloading positions can be opposite to each other

Curing chamber

- To shorten the curing time and reduce the required number of pallets

- Further increase in product quality (reduction of efflorescence)

- In galvanized steel version

- Available as a large-chamber or singlechamber system including empty chambers

- Complete system insulated and equipped with roller gates

- Various systems can be used to optimize the curing process:

- Specific heat

- By heat of hydration during curing of concrete - Vaporization

- Steam within a few seconds

- High efficiency

- Low emissions

- Low space requirement - Moisturization system

- No moisture formation due to standing fog

- Less water consumption

- Low energy consumption

For all curing processes, air circulation systems are advantageous for uniform temperature and moisture distribution inside the chamber.

- Air circulation systems

- For even distribution of air within the chambers

- Extraction of the chamber air to dry the chamber

- Direction of the chamber air after the curing process into a new chamber for preheating. Savings of around

20% of the heating costs

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.