Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

Station 2 & 3:

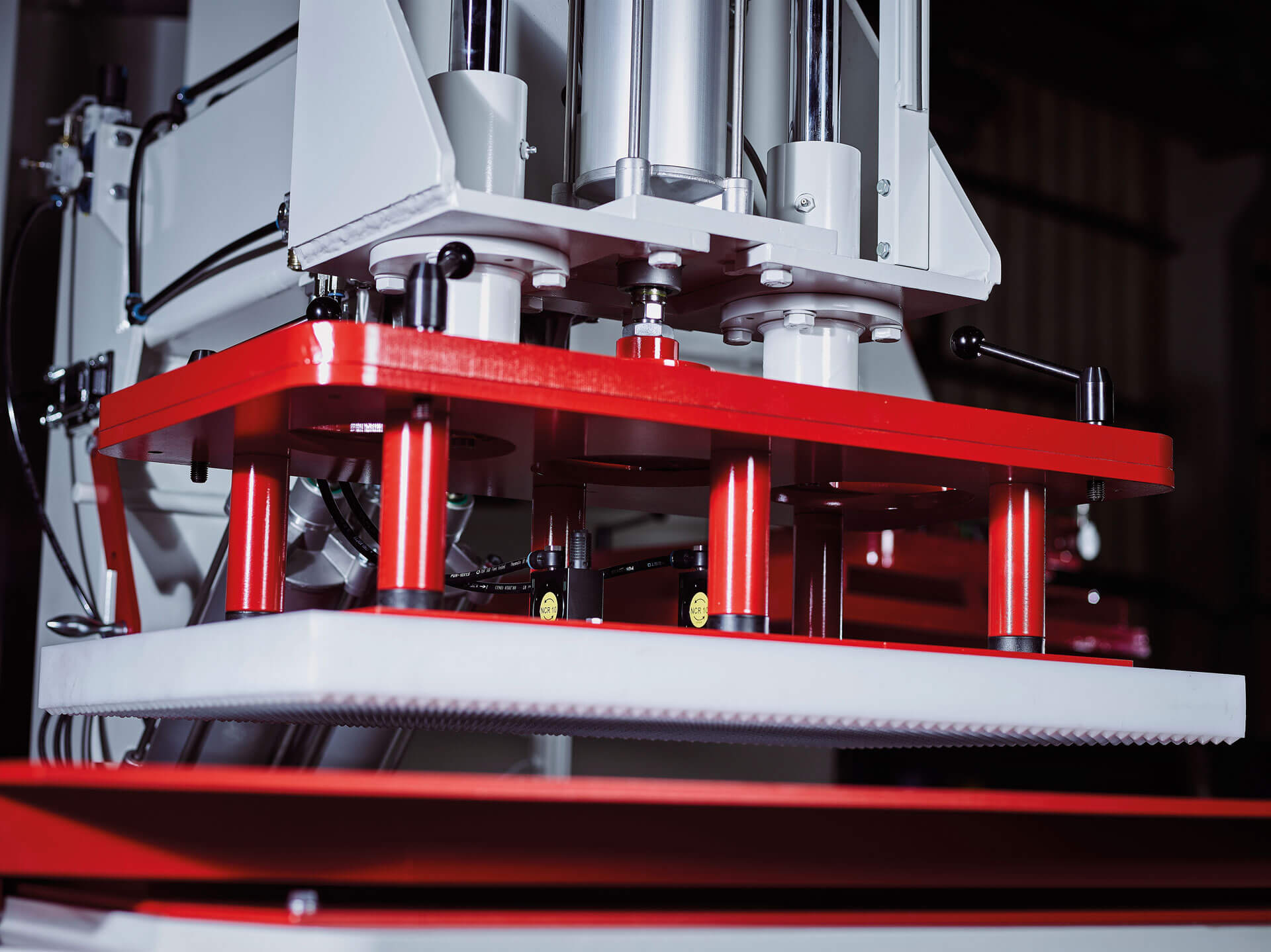

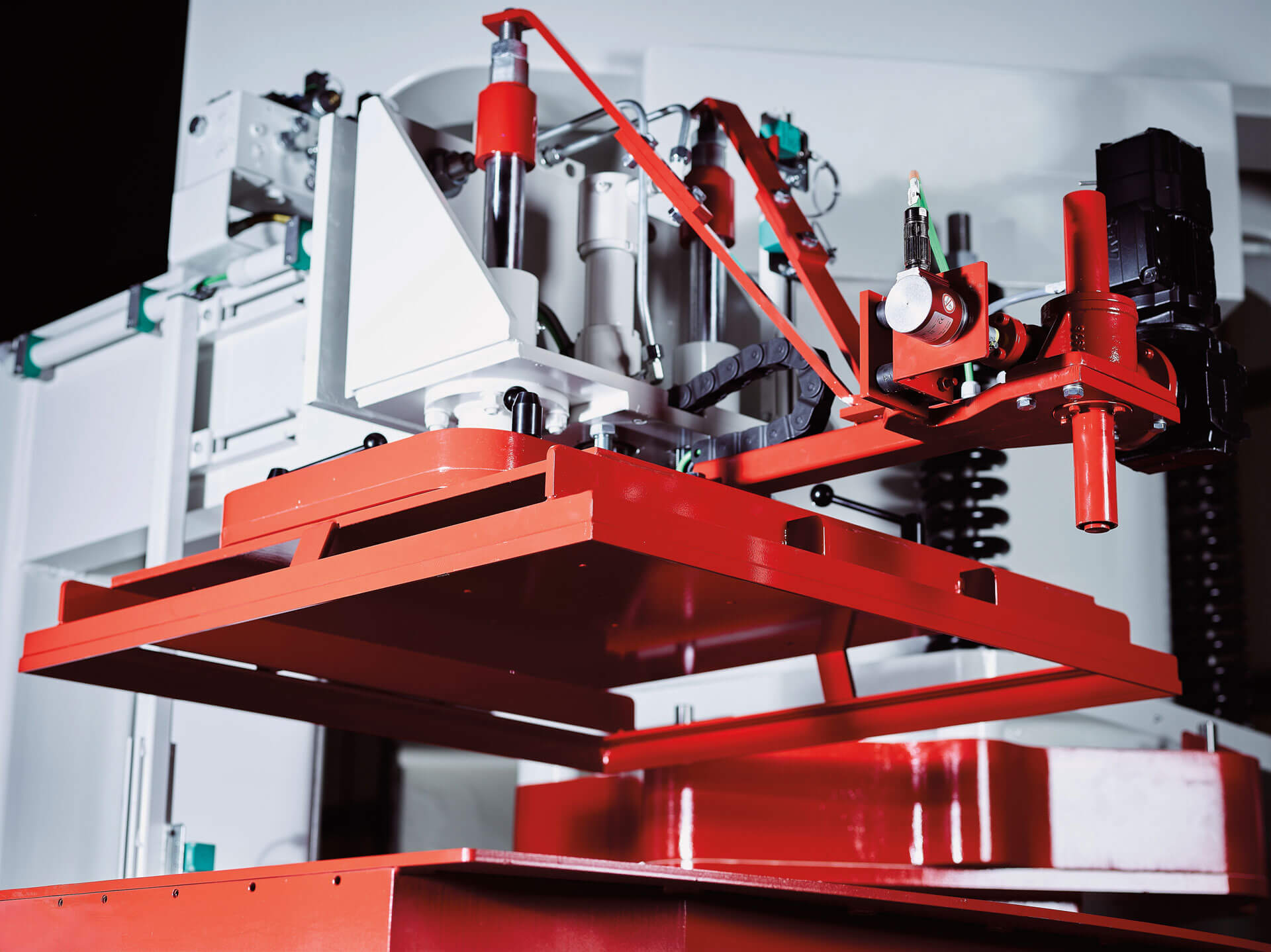

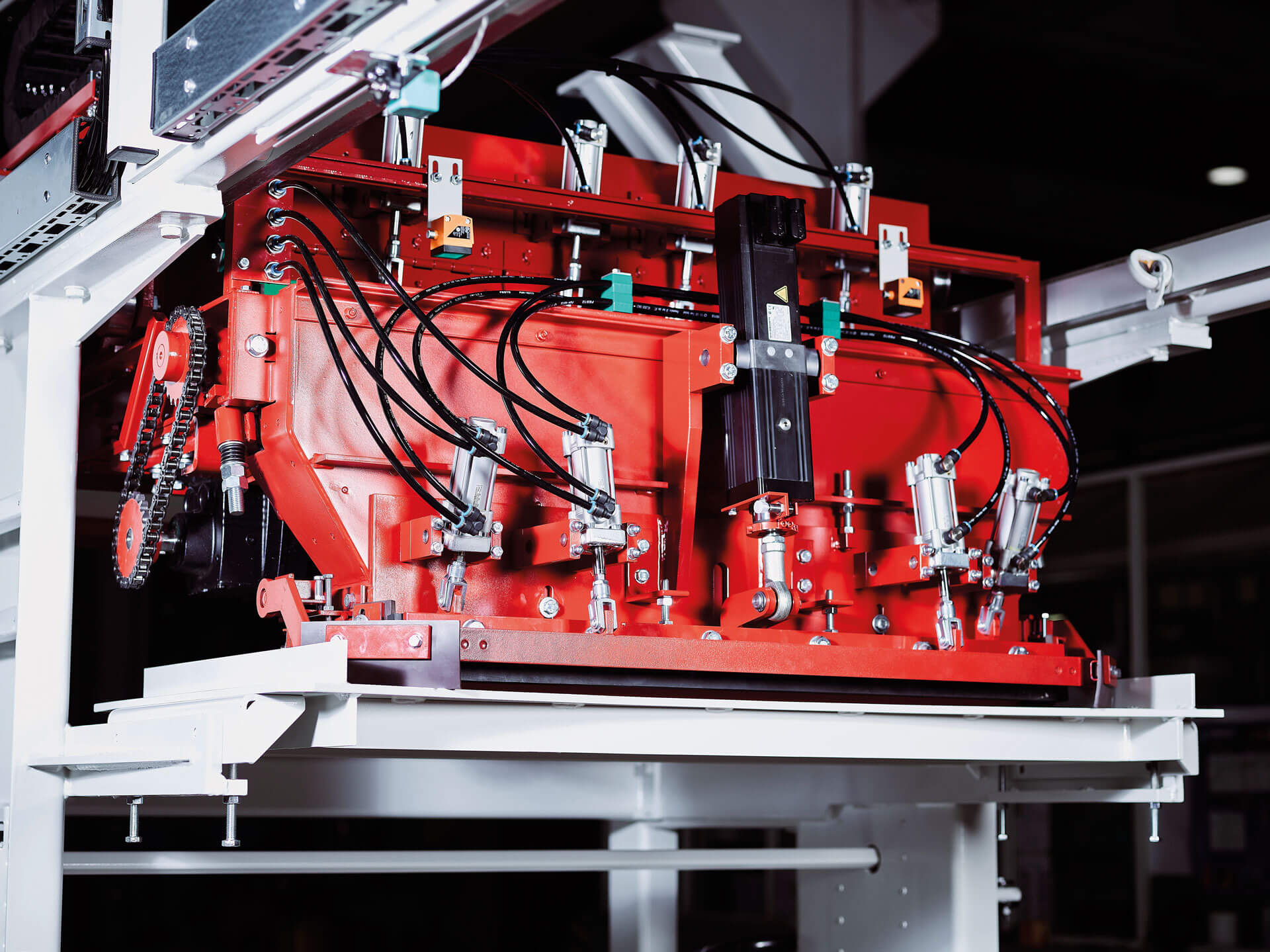

Facemix distribution and service station

Facemix distribution station

Advantages

- Precise distribution of the facemix

- Support for material de-aeration

- Prevention of pore formation

For optimum distribution of different facemix recipes, the following systems are available:

- Plastic stamps with different millings (adapted to concrete)

- Gratings

- Vulcanized facemix distribution plates

Optional Immersion depth adjustment

Electronic adjustment of the immersion depth of the facemix distributor during operation for quick adaptation to different material conditions

| Plastic stamp | Grating | Vulcanized | |

| Distribution of the facemix | ++ | ++ | + |

| Cleaning | ++ | + | + |

| Homogeneous surface | ++ | ++ | + |

| Non-stick properties | ++ | ++ | ++ |

+ = well suitable

++ = highly suitable

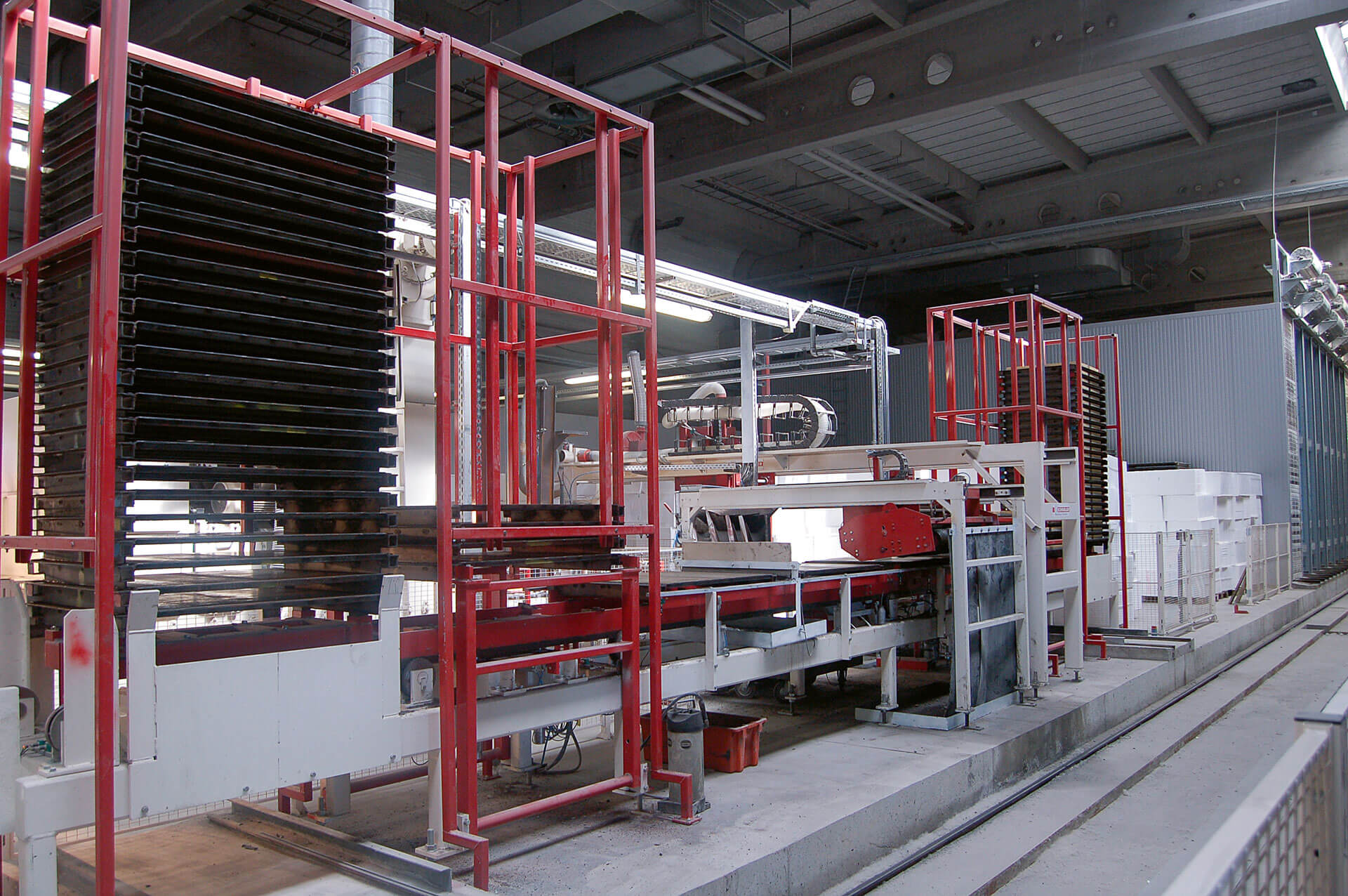

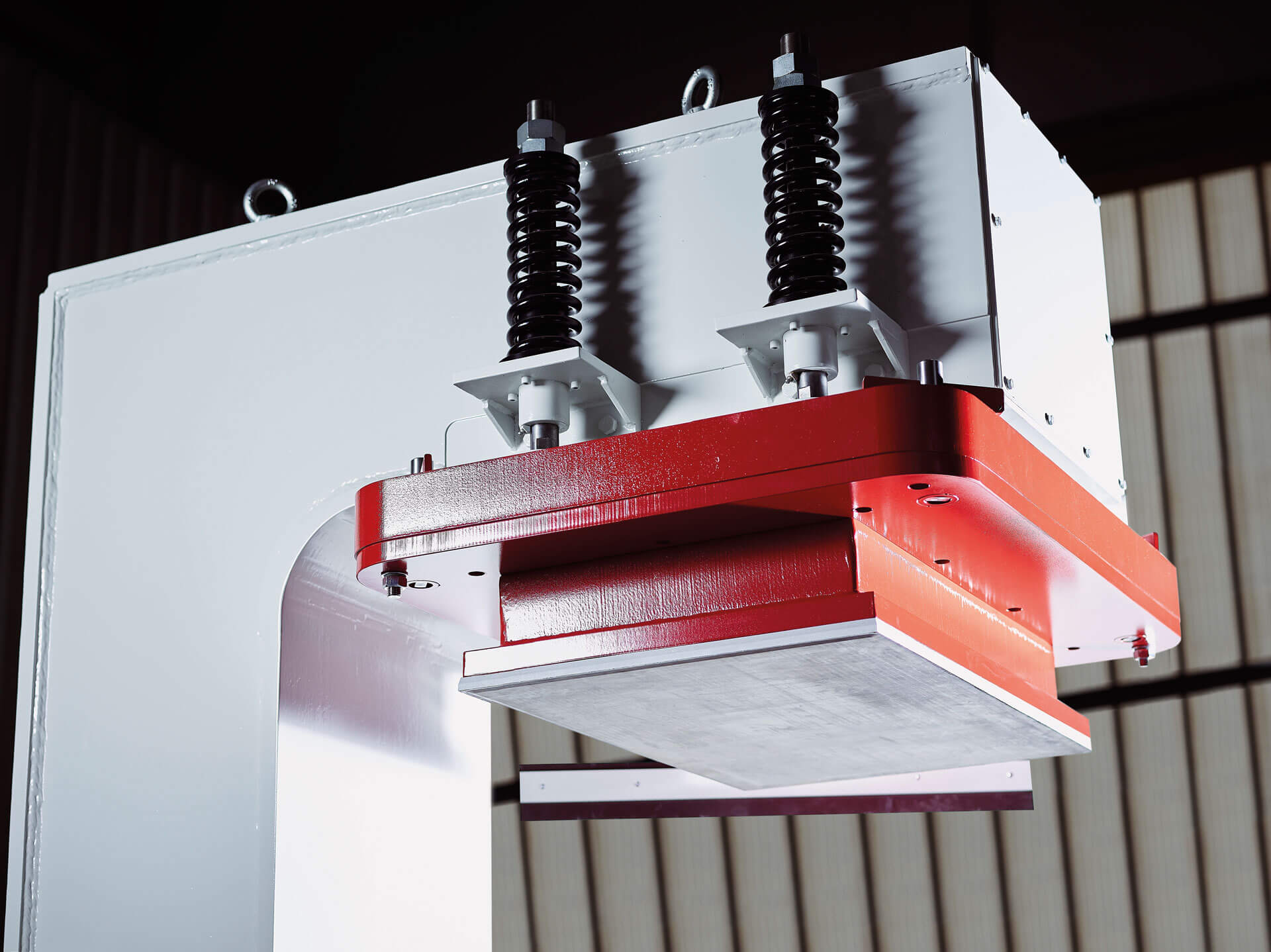

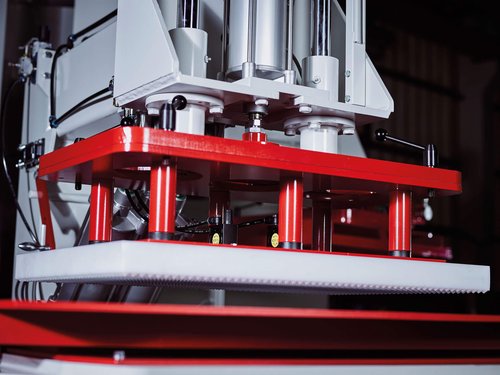

Service station

Advantages

- Easy and quick mould exchange

- If required, this station can be used as second facemix distribution station

- Monitoring of facemix distribution during ongoing production

For mould exchange, cleaning and control of mould frames. Here as well as at station 1 and 2, vibration in stop-and-go mode is possible.

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.