Contact

SR SCHINDLER

Give us a call:

+49 941 69682 69

support@sr-schindler.com

spareparts@sr-schindler.com

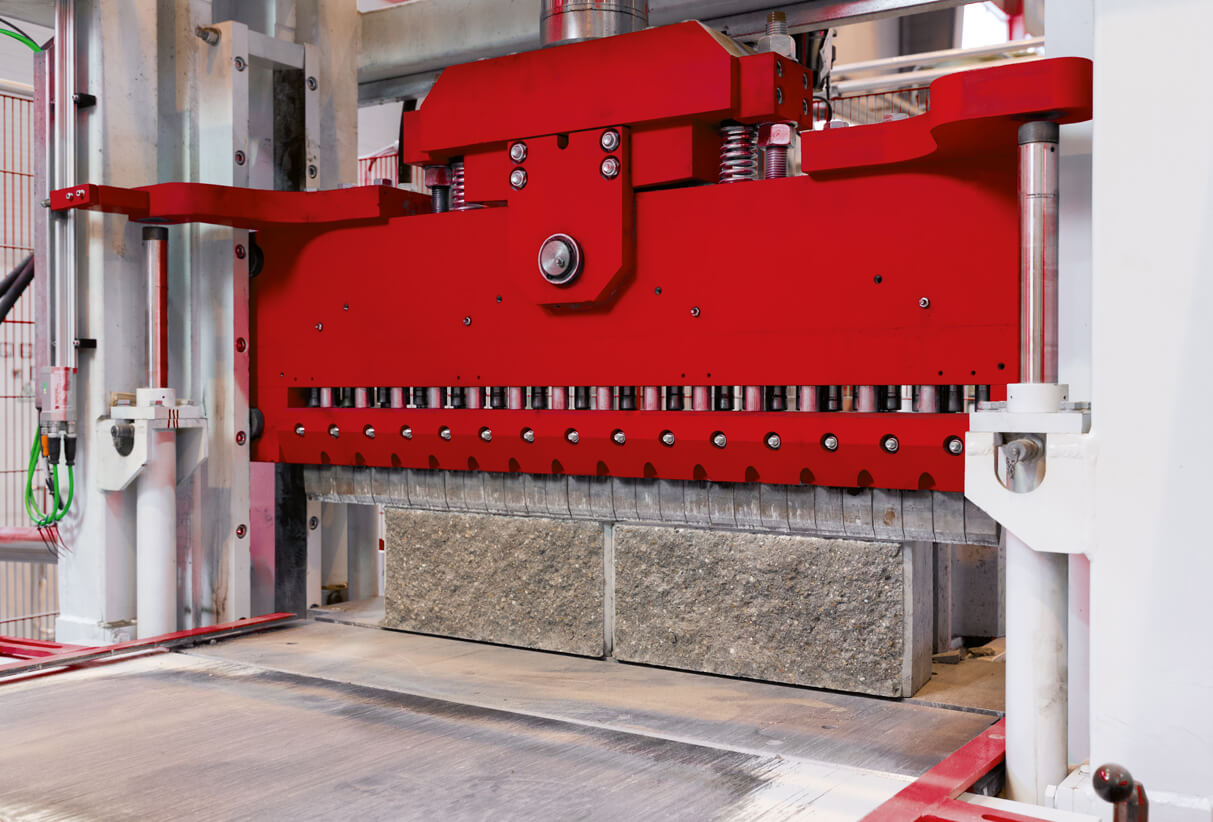

Splitting

Customer benefits

- Durable machine due to stable and high-quality construction

- Low reject rate due to very high splitting accuracy (clean break edges, exact positioning)

Of block stones, wall stones, hollow block stones, palisades and block steps.

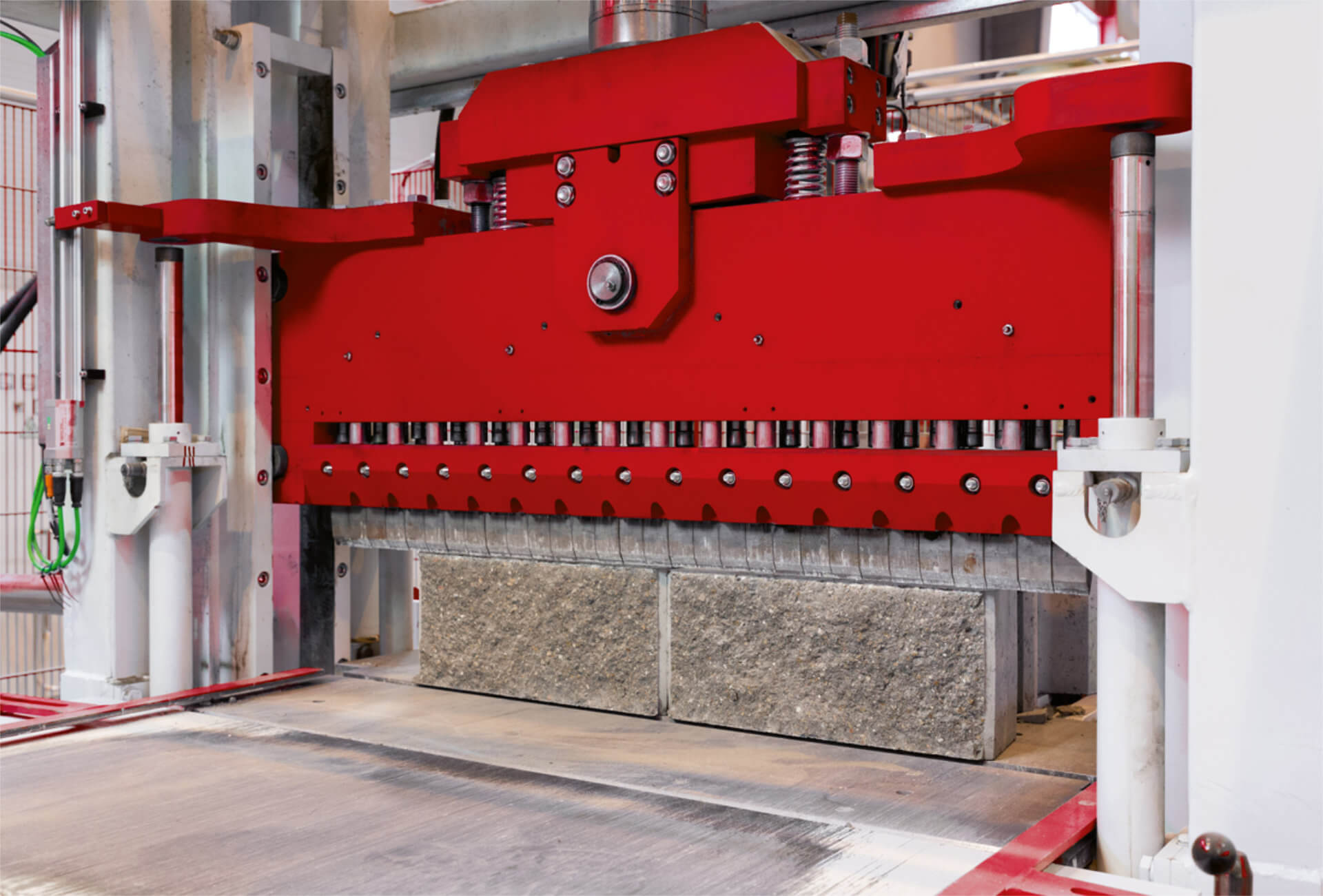

Equipped with high-capacity hydraulics with pressure accumulator for fast cycles, controlled splitting patterns and a maximum splitting pressure of 120 t. Equipped with upper, lower and lateral knives. Upper cutter bar moveable for compensation of height differences and for hydraulic height adjustment of upper cutter bar.

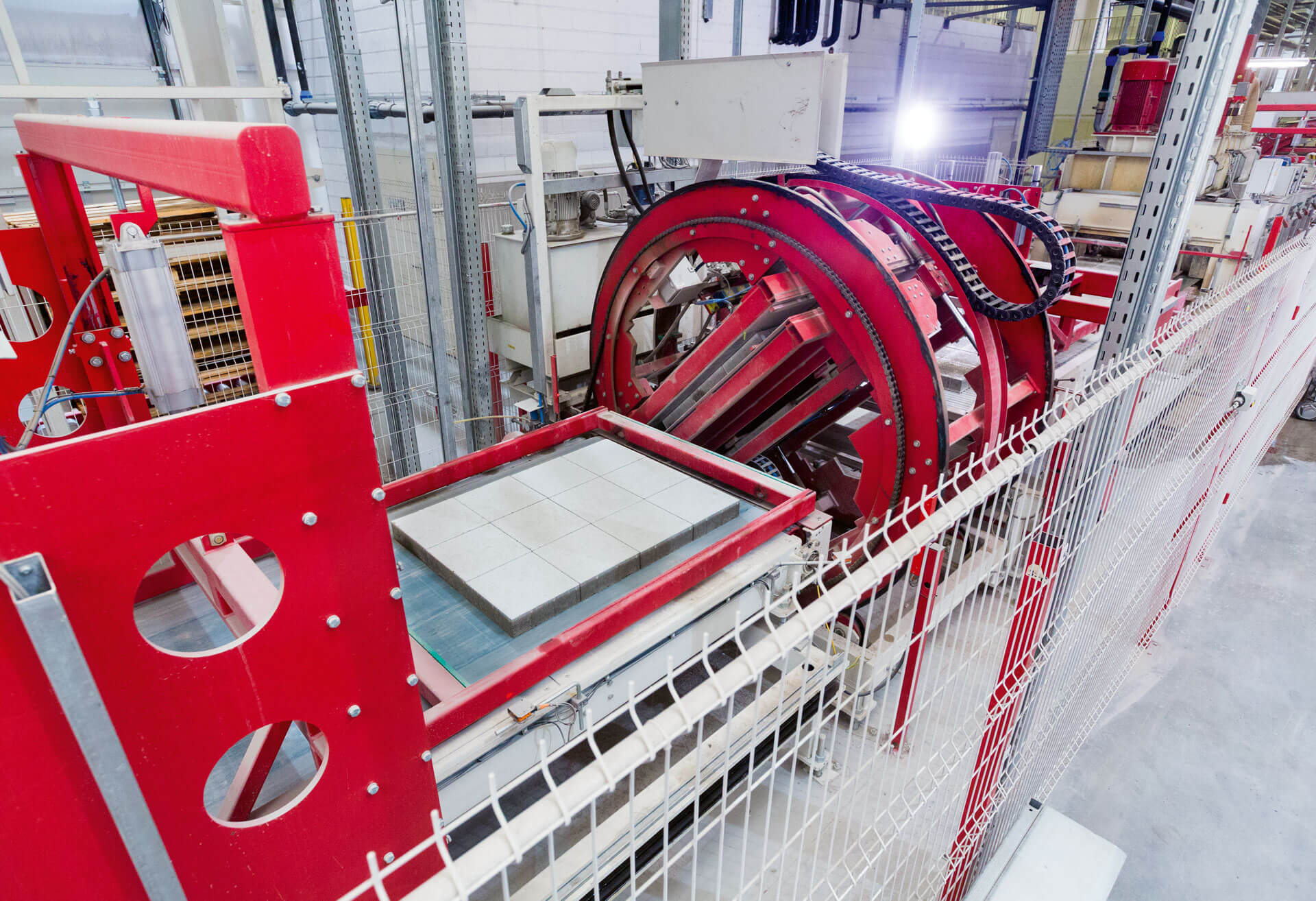

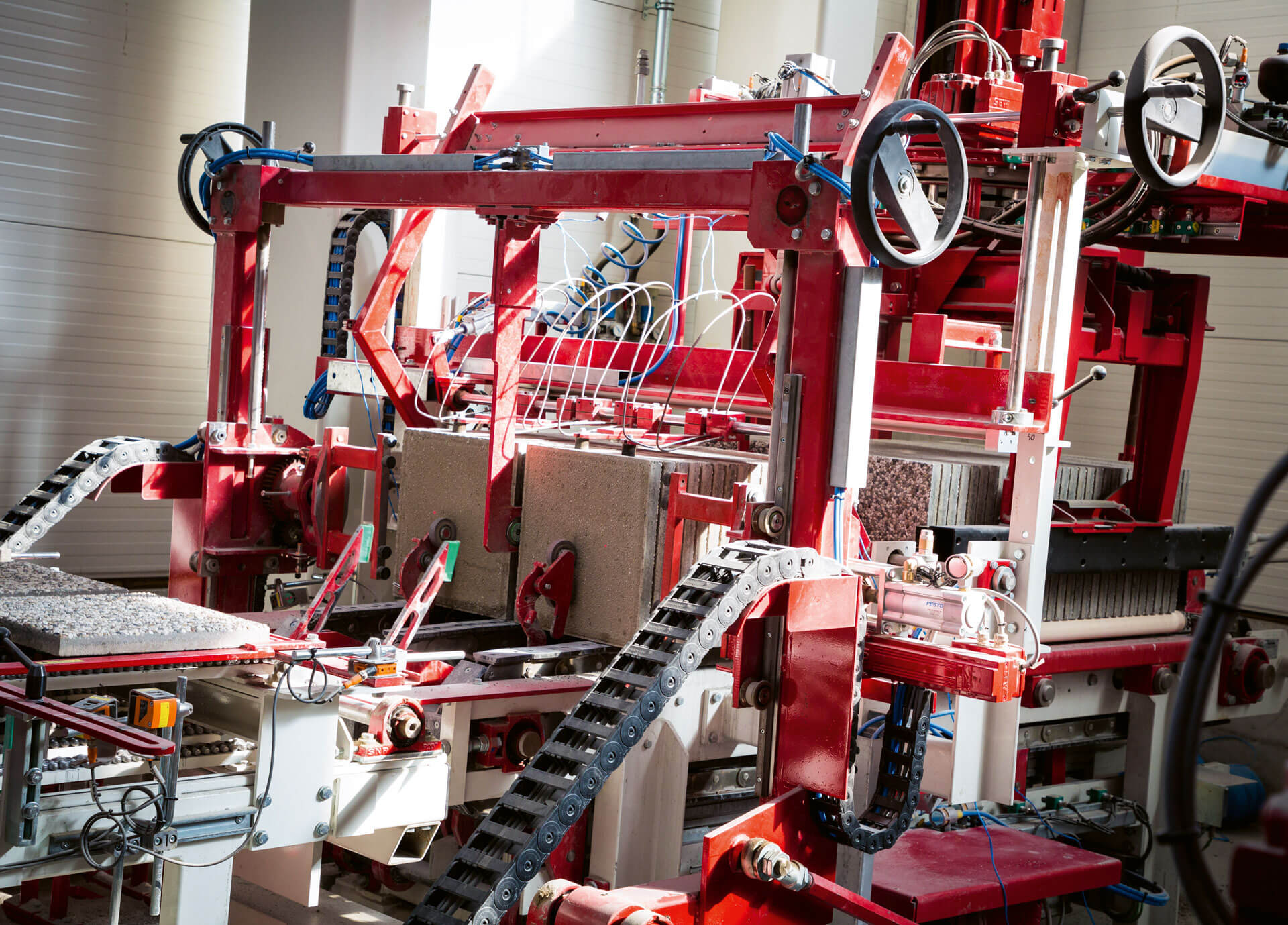

Splitting line available with one or two splitting machines with 90° rotating table for longitudinal and traverse split. Precise product positioning under the splitting knife by means of electromotor with encoder for accurate splitting and less waste. Feeding technology with automatic waste flap. Rearrangement, respectively formatting of split products that layers can be packed. Optionally executed for Y-split or special split. Can be combined with edge treatment machine for random chipping of edgesand with bushhammering/aging machine.

Technical specifications *

| Splitting cycle | |

| with product transport included | approx. 12 Sek. |

| * depending on product characteristics and required final result and also on product size and splittings to be carried out | |

TECHNICAL DATA

Product thickness: 50 – 350 mm

Working width: 800 mm/1,200 mm

| Model | 800 | 1200 | |

| Splitting width | 800 mm | 1,200 mm | |

| Passage width | 900 mm | 1,300 mm | |

| Splitting height | with side knives | 140-350 mm | 140-350 mm |

| without side knives | 50-350 mm | 50-350 mm | |

| Passage height | 410 mm | 410 mm | |

| Splitting pressure | 80 t | 120 t | |

| Connected load | approx. 12 kW | approx. 13 kW |

Concrete block refinement

creates room for creativity

The demand for diverse shapes and sophisticated surface designs, such as natural-looking stone surfaces, is constantly increasing.