Handling Systems

PRINZING PFEIFFER offers modularly built and optionally extendable handling systems for an automatic production process. These handling components can be used as a stand-alone solution (e.g. base pallet cleaning, pipe testing equipment, etc.) or fully integrated in complete production lines. New machinery as well as existing machinery can be extended as follows

- Base pallet handling

- Feeding devices (e.g. steps, transport anchors)

- Mould handling

- Product handling

- Product testing equipment

Quality assurance is particularly important in concrete pipe production. For testing and documentation of the concrete pipe quality, Prinzing Pfeiffer offers a pipe testing line whose test stations can be freely configured. This means that individual customer requirements can always be considered during the conceptual design phase.

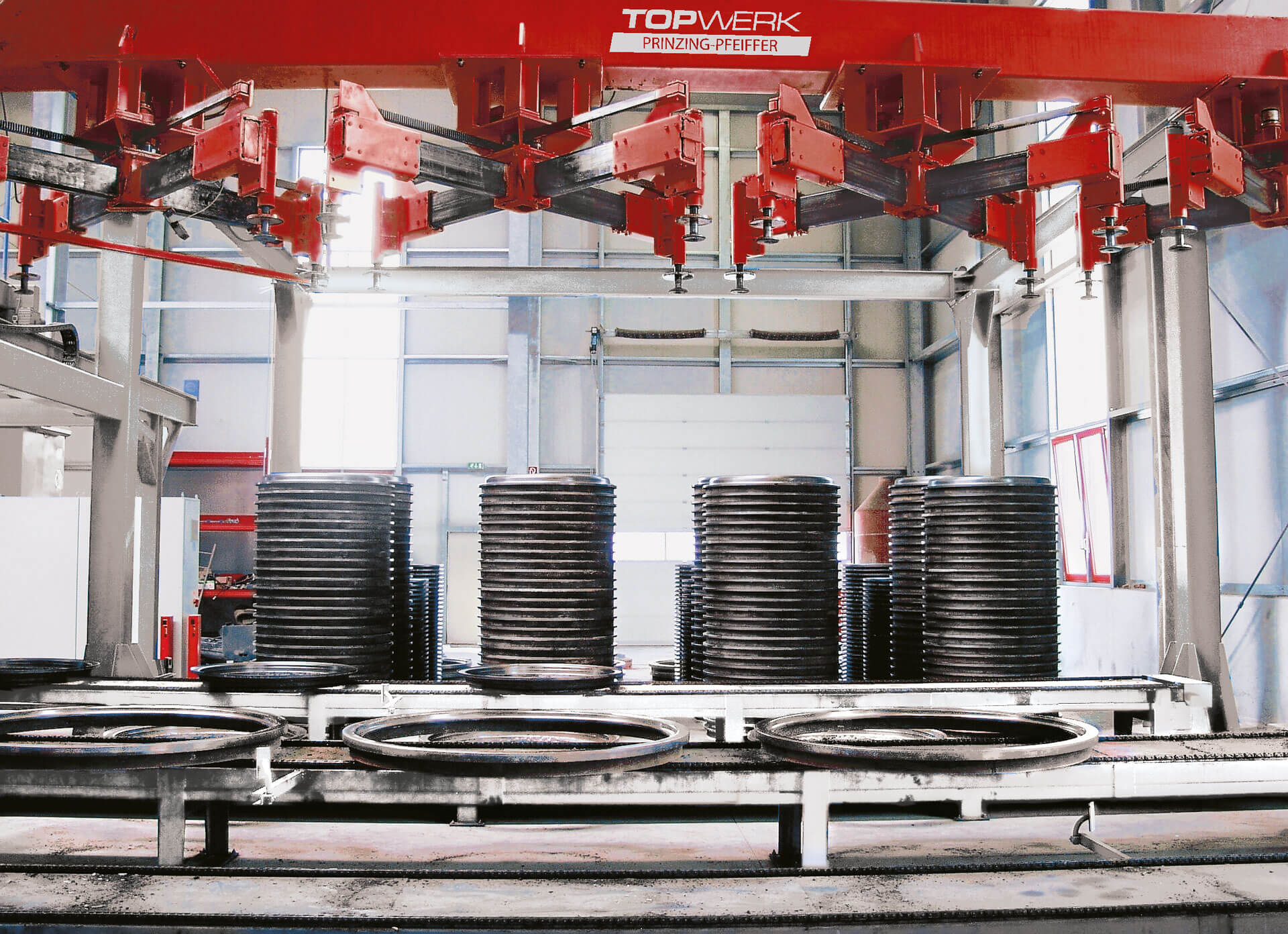

The pipe testing line from PRINZING PFEIFFER consists of several stations. Beginning with the pipe alignment there is also a deburring station for grinding the inside and outside diameters of the bell end and spigot end. This can be optionally extended with an additional milling machine for an additional groove in the spigot end for a concrete pipe with a subsequently installed spigot gasket. The automatic test for a possible pipe leaking will be carried out with a vacuum pipe testing device using the vacuum differential method. The pipe testing line can be extended by a length, roundness, and straightness measurement system.

The final station is normally an integrated pipe marking device to mark pipes by a special DOD inkjet printer according to customer requirements. For example pipe standards, production data, pipe dimension, the company name, or other information can be printed on the outside of the pipe.

A pipe deposit line with a movable pipe carriage ensures that the tested and marked pipes can be temporarily stored and finally picked up by forklift truck.

Advantages of out handling systems

- Modularly designed and optionally extendable

- Universally usable for different machine types

- Use of high-quality automatization components

- Logically thought-out operation plan

- Increase in productivity

- Increase of quality

- Reduction of personnel

- Improvement of working conditions